Date: 31 October 2024

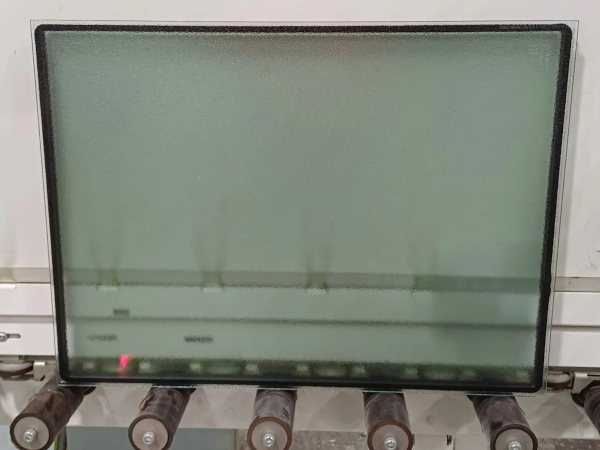

Sparklike is pleased to highlight the British Fenestration Rating Council’s (BFRC) recent adoption of the Sparklike Laser Portable™ 2.1, making them the first in the UK to integrate this advanced gas measurement device. As distributed by Inagas, the Sparklike Laser Portable 2.1 was selected for its precision, portability, and ability to measure gas concentration in both double and triple-glazed units, even through coatings and laminations.

For BFRC, the device addresses a critical need for non-invasive, on-site gas concentration measurement, enhancing their testing capabilities and allowing them to provide comprehensive on-site inspections without compromising IGUs.

Key Advantages:

- Non-invasive Measurement: Enables accurate gas analysis in sealed units without breaking glass.

- Portability: Compact and suited for both factory and on-site use, increasing operational flexibility.

- Precision through Coatings: Measures gas concentrations through most coatings and laminated glass.

- Enhanced Performance: A 12-inch screen, barcode reader, and extended six-hour cordless operation make the device ideal for varied environments.

Commitment to High-performance Insulating Glass

BFRC’s Managing Director, Richard Sellman, emphasized that this upgrade allows them to offer on-site IGU gas concentration determination, further expanding their services to meet industry needs. With this adoption, BFRC demonstrates a commitment to enhancing industry standards through advanced technology, supporting the growing demand for high-performance insulating glass.

The Sparklike Laser Portable™ 2.1 provides a robust solution for companies in the fenestration industry looking to improve the quality and reliability of their gas concentration measurements. By integrating this tool into your operations, you can ensure compliance with energy performance standards and offer precise, non-invasive testing both on-site and in the lab.

Read the original story here: https://www.inagas.com/news.php?article_id=83

600450

600450

Add new comment