Via Fieramonti 1

Cisterna di Latina 04012 LT

Italy

Mappi International Srl

Company address

COMPANY DESCRIPTION

Manufacturer of tempering furnace for flat glass, laminating system.

COMPANY ACTIVITY

Manufacturer

SIMILAR COMPANIES

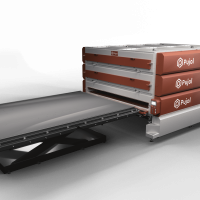

Hornos Industriales Pujol

Carrer del Pla, 108-110, Pol. Ind. El Pla

08980 Sant Feliu de Llobregat Barcelona

Spain

Luoyang North Glass Technology Co., Ltd.,

No. 20 Binhe Road, High-tech Development Zone,

Luolong Qu

Luoyang Shi

Henan Sheng, 471003

China