Latest articles

| Viprotron has developed a new technology for the exit of the furnace, that allows the measurement of the distortion of tempered glass with high precision and unparalleled repeatability.

| The two common defects—White Haze and Anisotropy—are often misunderstood but are not the same.

| Implementing quality controls and checkpoints during production and inspecting 100% of the tempering process, guarantees less rejections in the field converting into more profit.

| The new complete metrology scanner after furnace exit and its capabilities for furnace optimization and quality control.

| This article explores the various aspects of PVB Preparation, handling, and assembly. It explains how to store, transport, and handle PVB in order to ensure optimal performance and adhesion.

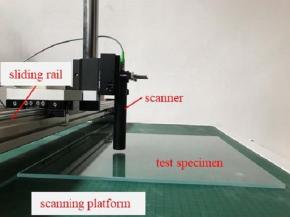

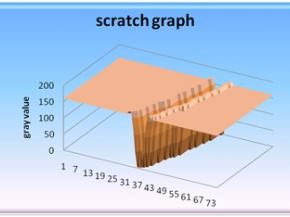

| This study aims to develop a non-contact stage-wise scanning method to extract 3D damage characteristics on glass surface, which can further facilitate the investigation into the associated influences on the flexural strength of glass.

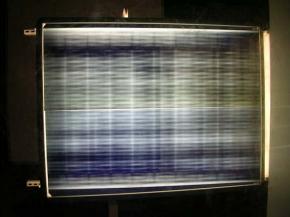

| In the present paper, optical anisotropy effects in architectural glass are evaluated using digital image processing.

| The intention of this paper is to address this gap with the aid of photoelasticity as an indirect measuring method in a coordinated way with numerical simulation based on finite element analysis.

| Industry demand for impeccable glass quality has increased notably over the last years. Customer expectations run high, forcing glass processors to strive for ever-stricter quality control and ensure minimal rejection rates for finished products.

| The most common quality issues that arise in tempered glass are roller waves, glass distortion, bad anisotropy and white haze. In this post, we want to focus on white haze and ways to control it.

| The aim of this paper is to identify and discuss challenges with the assumption that the SSG is isolated from the glass self-weight and provide a better understanding on the complexity of SSG systems.

| This paper was first presented at GPD 2019 by Louis Moreau from AGNORA, Canada.

| In a glass tempering process, residual stresses to glass are made with heat treatment. The process includes heating and cooling, and they should be equal on both sides of the glass pane.

| Following a short overview outlining key design objectives, the fabrication process of an opaque composite glass panel is described in detail.

| In the last years contentions about anisotropies among customers and manufacturers occurred when using glass products, such as heat-strengthened (HS) or fully tempered glass (FT).

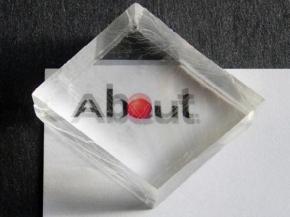

| Glass distortions may cause objects to appear irregular and out of focus when observed through a distorted glass panel.

| A couple of years ago all started with the first measurement of anisotropies and edge stress as well as the detection of White Haze and other glass imperfections right after the furnace.

| Arup are consulting engineers for a series of recent projects involving curved glass: The High Roller observation wheel in Las Vegas and a revolving feature lift for the new Louis Vuitton townhouse in London.

| This blog post was written based on an interview with M.Sc. (Chem.) Santtu Jolkkonen, Sparklike's Service and Maintenance Manager, who has been working as technical support specialist for Sparklike over a decade.

| Glass industry standards in different countries require 24/7 quality control with the same specifications and fully automated analyses and following statistics.