This paper was first presented at GPD 2023.

Link to the full GPD 2023 conference book: https://www.gpd.fi/GPD2023_proceedings_book/

Authors:

- Barbara Siebert - Dr. Siebert and Partner Consulting Engineers PartGmbB, Munich

- Tobias Herrmann - Dr. Siebert and Partner Consulting Engineers PartGmbB, Munich

Introduction

Wide-span glass roofs are becoming increasingly popular as they provide transparent roofing for atriums or entrance areas. Most often, IGU`s (Insulating glass units) are used. As a construction element often inclined transom - mullion constructions are used, in detail with drawn aluminum profiles (including screw channel) or steel constructions with a special add-on construction.

Architectural and structural design

There are many points to consider during planning and execution: First of all, the planning of the roof is particularly important: the less sloping the roof, the more important is a very good quality of execution. As a limit, the inclination should not fall below 7 degrees. Since the lower drainage level of the transoms should drain in the direction of the mullion, transoms that are too wide are unfavorable, as they bend and drainage is no longer possible.

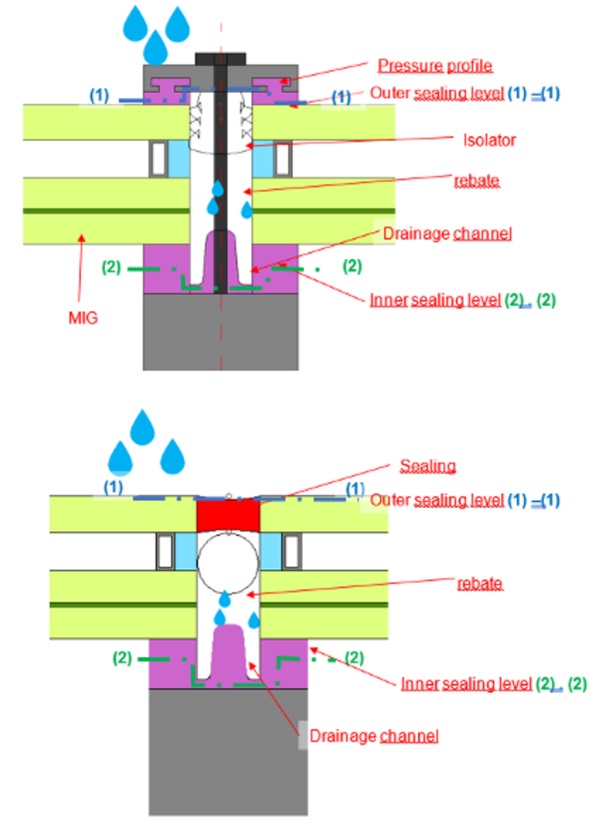

Transom - mullion constructions consist of 2 sealing and drainage levels. As soon as water penetrates the outer sealing level, the water must be drained away in the lower drainage level. This requires compliance with many specifications, especially during execution. For example, the crossing points must be tight, and the support EPDMs must be latched and bonded in an unlocking manner. Unblocking ventilation or vapor pressure equalization of the inner drainage level must be ensured. Of course, a structural analysis has to be done. This concerns the glass, the substructure made of steel and aluminum, but also the detail points such as screw channel, glass support and transom connectors.

Cases of damage

A large proportion of cases of damage in structural glass engineering relate to leaking glass roofs: this is caused by roofs with too low inclination, transoms that are too wide, systems in which the screw connection penetrates the lower sealing level, faulty bonding of the seals, water accumulation in the drainage channel, filling of the glass rebate with silicone, a too small contact pressure and much more. One example is shown in Figure 2.

Examples

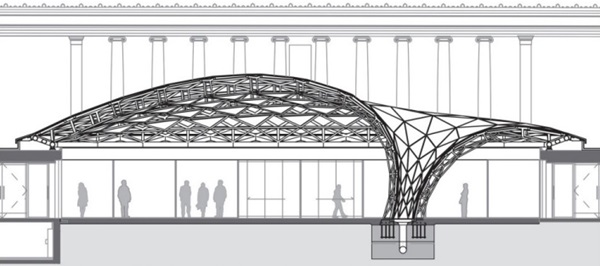

A particularly challenging glass roof is the roof of the Albrigtht Knox Art Museum in Buffalo USA. Although the span is not extremely large, the geometry is a freeform with triangular glass panels. The spectacular "Common Sky" design by Berlin-based design and architecture firm Studio Other Spaces (SOS) for the roofing of the existing of the existing courtyard was in line with the museum's desire to create a modern open and modern art institution for all people.

Eliasson and Behmann use a natural formal language and mark with the funnel-shaped support the place in the inner courtyard where a tree was once planted. Free-form surfaces are being used more and more frequently in architecture, not least because of the everincreasing computing power and powerful planning tools. The project discussed here was also spatially designed according to all rules of the art and down to the last screw. The roof artwork was executed by the German company Hahner Technik GmbH & Co. KG. Structural Design of the substructure was done by the Company ArtEngineering, our office Dr. Siebert and Partner was responsible for the glass.

A major feature of the Common Sky is the division of the outer shell into triangles and equilateral hexagons. While free-form surfaces can be relatively easily meshed or approximated by triangular surfaces, the design-based choice leads to a conflict: six triangles each form a hexagon in the plane at their center. If the latter is lifted out of the plane, this leads to the fact that the edges of neighboring triangles are no longer straight or parallel to each other.

A sealing profile was developed which is placed over the screw channel and allows sufficient support depth for the insulating glass units. With three drainage levels, the rebate spaces were cascaded at the star-shaped junctions to follow the gradient. A planning and technical challenge was posed by the numerous skewangled gasket joints. To reduce errors and inaccuracies on the construction site, all seals were cut to size and bonded in the factory using a specially developed process. This meant that only straight joints at the level of the bolted joints in the supporting structure had to be closed on site.

References

[1] Herrmann Tobias, Common Sky – ein Dach als Kunstwerk, Glasbau Dresden 2023, Ernst und Sohn