Innovations in silicone sealants have made structural glazing the bridge between architectural vision and construction reality, delivering a powerful combination of aesthetics, performance, and long-term durability.

In this feature, Momentive’s Application Development Leader Errol Bull reflects on the history of structural glazing, from the first use of silicone sealants in curtain walls to today’s soaring towers.

A Timeline of Structural Silicone Glazing

- 1964: First structural bonding projects in the U.S. using 1-part silicones

- 1968: First two-sided SSG curtainwall emerged

- 1971: First four-sided SSG system was installed (Detroit, MI), with additional safety devices

- 1974: First four-sided SSG project without safety devices was completed at the School of the Art Institute of Chicago

- 1984: First generation of two-part silicone developed in the U.S.

- 1985: IFT façade project in Rosenheim, Germany – toggle system, no safety devices, lifetime monitored

- 1990–1993: Next-gen two-part silicones meet European standards; first SSG system approvals in Germany

- 2019: 50th anniversary of the School of the Art Institute of Chicago, the first known four-sided structural silicone glazing installation

- 2023: 30 psi adopted as the industry standard for design stress requirements.

Origins: A New Era Begins

Silicone’s industrial history dates back to the late 1930s, with Eugene G. Rochow at GE and Dr. James Franklin Hyde at Dow Corning pivotal in the development of scalable production. Silicone then became a key part of the World War II war effort, with its resistance to heat, moisture and UV making it a key component in aircraft and electronics.

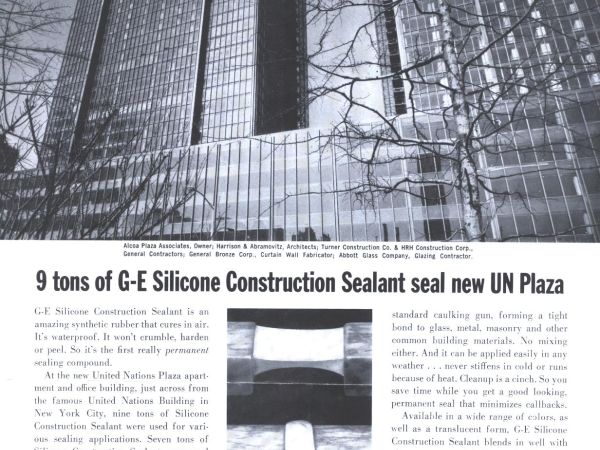

By the 1960s, GE had introduced its first silicone-based sealants and coatings, marking the beginning of a new era of architectural design freedom. A landmark early example was New York’s United Nations Plaza Towers (1964), which used GE’s SE-1200 Weather sealant. This marked a pivotal shift, as sealants could now be used to protect building exteriors from elements like wet weather, UV, and extreme temperatures. By the mid-60s, silicone sealants were serving a structural role, bonding glass to frames and unlocking new possibilities for performance and aesthetics.

GE continued to lead the industry for decades, when in 2006, it became Momentive Performance Materials. Today, Momentive continues to build on this legacy of silicone innovation, shaping the modern world's skyline.

Building the Framework: 1970s to 1990s

The 1970s witnessed the rise of small-scale SSG projects, the introduction of early four-sided glazing and the emergence of unitized façades.

One of the standout projects of that era was the School of the Art Institute of Chicago, home to the first known four-sided structural silicone glazing installation. Completed in 1974 using SilPruf SCS2000 sealant, this system has remained intact for 50 years – a remarkable achievement in building envelope durability and a testament to the longevity of silicone structural glazing systems.

By the 1980s and 1990s, structural glazing had become a global phenomenon. Architects and engineers pushed the boundaries of design, integrating more complex shapes, materials and sizes into the building envelope. During this period, GE introduced non-acetoxy, neutral-cure silicones for improved compatibility and safety, and developed robust two-part SSG sealants designed to support higher structural loads.

That evolution can be seen on the MGM Grand. When it opened in 1993, it was the largest hotel in the world, with Momentive’s SSG4400 sealant chosen for structural glazing and in-shop curtainwall fabrication.

A New Millennium of Ambition

By the early 2000s, the term "supertall" had become part of the architectural vocabulary. Buildings between 300 and 599 meters (984 and 1965 ft) redefined skylines from Asia to the Americas. But with height came a series of new challenges: seismic forces, extreme wind pressures, larger glazing units and stricter energy performance standards.

UltraGlaze SSG sealants were engineered to meet these demands. Tested to meet global standards such as ETAG 002 (Europe) and GB/T 16776 (China), these advanced silicones allowed façades to remain flexible and intact under extreme conditions, including hurricane-force winds and blast impacts.

The Shanghai Financial Center, standing at 492 meters and completed in 2008, is an excellent example of the evolution of the silicone and construction industry.

Today’s High-Performance Silicone

Today, Momentive’s structural silicone products are integral to some of the most impressive structures of the modern era. Structures like Central Park Tower in New York, the world's tallest residential building, and the upcoming Rise Tower in Monterrey, Mexico, are underpinned by several UltraGlaze structural glazing sealants, both of which were chosen for their design flexibility and field-tested durability.

Historically, one important milestone is the Cass Building, located at 455 West Fort Street in Detroit. The building was the first to feature four-sided structural silicone glazing. And, despite initial concerns, the building turned 50 in 2021, reaffirming SSG’s importance in façade engineering.

Perhaps one of the most impressive of modern structures is Apple Park, Apple’s headquarters in Cupertino, California. Known as “the spaceship,” it is the largest glass-supported building on Earth, featuring curved panels that span up to 47 feet in length. The structure showcases the seamless integration, strength, and aesthetic freedom - all enabled by SSG technology.

The Modern Benchmark

The latest generation of UltraGlaze structural glazing sealants are built to meet 30 psi design stress requirements (updated by ASTM in 2023), offering:

- High tensile strength for narrower mullion designs and higher wind pressures.

- Excellent elasticity and tear resistance, helping façades absorb movement and stress without cracking or failure.

- UV and weathering resistance help deliver decades of flexibility in harsh environments.

It’s important to note that while older-generation silicones and competitor products can lose flexibility or adhesion over time, Momentive’s new formulations remain flexible – an essential trait for accommodating thermal expansion, wind loads, and building movement.

Tested to the Extreme

Momentive has a two-fold approach to testing – as well as its impressive lab testing, it puts its sealants to the test in real-world situations.

Structural silicone sealants are subjected to blast tests, seismic cycling, and over 50,000 pressure cycles at test pressures exceeding 1,000 pounds per square foot (psf). The results? Glass may fail, but the silicone holds.

In one blast simulation run by a third-party testing lab, loads reached 1,140 psf – over 10 times the typical design pressure. Despite the intensity, the silicone joints withstood the force, demonstrating resilience not only under code-level stresses but also under catastrophic events.

Why Glazing Engineers Trust Structural Silicone

So, why do façade engineers and architects continue to choose structural silicone after all these years? It comes down to performance over time. The following benefits have proven decisive on projects around the world:

- Long-Term Durability: Unlike organic sealants, silicones do not become brittle or shrink over time. Projects completed 30–50 years ago remain sealed today.

- Design Freedom: Structural silicone enables glass-to-glass, mullion-free designs that traditional mechanical fasteners cannot support.

- Energy Efficiency: With excellent thermal resistance and compatibility with triple-glazed and gas-filled IG units, silicones support next-gen building codes.

- Safety and Resilience: In areas prone to hurricanes or earthquakes, properly engineered silicone glazing systems provide life-safety benefits without sacrificing aesthetics.

Conclusion: A Legacy of Performance

As buildings become taller, façades become more complex, and climates become more demanding, the role of structural silicone will continue to grow.

Today, the best structural silicone glazing sealants must offer:

- 30psi design strength

- High flexibility & stability

- Protection against environmental effects

- Quick, primerless application

Momentive continues to invest in next-generation glazing solutions, supporting everything from jumbo glass panels and curved units to blast-resistant assemblies.

Projects such as the Shanghai World Financial Center, Central Park Tower in New York, Cayan Tower in Dubai and Mahanakhon in Thailand showcase the diverse range of high-performance façades made possible by advanced SSG systems.

Structural silicone has enabled the transformation of glass façades from simply being weather barriers into stunning, high-performing design elements. Momentive’s decades-long leadership in silicone chemistry continues to push boundaries today.

For architects, engineers, and specifiers seeking proven solutions, UltraGlaze structural glazing sealants offer more than performance – they offer peace of mind. Backed by lab and field testing, and trusted in some of the tallest buildings in the world, they prove that silicone isn’t just a choice. It’s a legacy.

About Errol Bull

Errol Bull, P.E., CSI, is an Application Development Leader at Momentive Performance Materials Inc. Member: IIBEC, ASTM C24, ISO TC59/SC8.

With over 25 years of global experience in construction sealants, adhesives, and coatings, Errol is an expert in structural glazing and sealant performance. He holds a Bachelor of Science in Architectural Engineering and a Master of Science in Civil Engineering.

About Momentive

Momentive’s silicone solutions for building envelopes include high-quality sealants and coatings designed to extend life and enhance the performance of buildings worldwide.

The UltraGlaze SSG product family includes one and two-part 100% silicone-based structural sealants and adhesives. For new construction or renovation of building envelopes, including monumental curtainwalls, window walls and glass façades, you can depend on SSG products.

However complex and ambitious, turn your vision into reality with UltraGlaze™ Structural Glazing Sealants.

For more information, visit: https://siliconesforbuilding.com/