This paper was first presented at GPD 2023.

Link to the full GPD 2023 conference book: https://www.gpd.fi/GPD2023_proceedings_book/

Authors:

- Matthias Fahland - Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology (FEP), Dresden, Germany

- Jolanta Sczelwicka - Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology (FEP), Dresden, Germany

- Jaroslav Vlček - Department of Physics. University of West Bohemia, Pilsen, Czech Republic

- Jiri Rezek - Department of Physics. University of West Bohemia, Pilsen, Czech Republic

Abstract

Vanadium oxide is a well-known solid state thermochromic material. It undergoes a phase transition which is accompanied by a sharp change in the electrical conductivity as well as in the reflectivity for infrared radiation. This makes the material interesting for intelligent windows. However, it is very challenging to deposit Vanadium oxide in the correct crystallographic structure on a large area with sufficient reliability.

The authors present results achieved in a roll-to-roll deposition process of vanadium oxide on flexible glass of 0.1 mm thickness. The deposition width was 300 mm. The thermochromic material was embedded in zirconium oxide top and bottom layers which served as an antireflection layer and a crystalline template, respectively. A reactive high power impulse magnetron sputtering (HIPIMS) process was implemented. It was applied to a metallic rotatable vanadium target of 650 mm length. A closed loop control stabilized the oxygen partial pressure during the sputtering process. The tungsten doping (1.2 at%) of the target resulted in reduction in the phase transition temperature of the deposited layers from 68°C for pure vanadium oxide to a temperature below 30 °C. This is well suited for intelligent glazing solutions. The exact control of the sputtering process is essential for achieving the correct crystalline structure of the layer.

The thin glass with the thermochromic layer system was laminated to thicker panes for the integration in roofs and windows. First performance data in mockups will be presented.

Introduction

The building sector has a share of more than 40 percent of the total primary energy consumption in Europe [1]. With this background, the efforts for increasing the energy efficiency of buildings have been intensified over the last years. Naturally, the glass technology plays an important role for the transparent part of the building envelops, i.e. the windows and the skylights. Window technology looks back to a 4000 year history of developments. However, only since the 70th years of the last century energy efficiency became the crucial topic for research. Since then, low emissivity and solar control coatings, implemented in integrated glass units (IGU), have been the main innovations. Today the climate change and the increased pressure to reduce carbon footprint cause a demand of further improvements. With this background, smart coatings attracted increasingly attention. The question raises to which extend they can add their share for improving the energy balance in the living sector.

Smart coatings are distinguished by the fact that they can change their optical properties according to particular condition of weather, daytime, season or geographic location. The most common type is the electrochromic coating. It changes its appearance in the visible spectral range depending on an electrical impulse which is provided by either a human or a control system. The adaptation extends to the near infrared spectral region for some types of these materials. There are other types of smart coatings based gasochromic or photochromic materials. The special emphasis of this article is put on thermochromic materials.

This is a class of substances that change their properties in response to the temperature. Vanadium oxide is the best known thermochromic material. It has recently attracted attention because of its potential in energy saving applications [2].

In this paper a roll to roll process for the deposition of vanadium oxide is introduced. It is based on a preceding laboratory study of the group of Vlzek [3,4]. They promoted the reactive sputtering of vanadium oxide by high energy impulse magnetron sputtering (HIPIMS). The active layer was embedded in two layers of zirconium oxide. They served as template (bottom layer) and protection (top layer), respectively. Furthermore, the embedding layers improve the optical performance of the stack.

Experimental

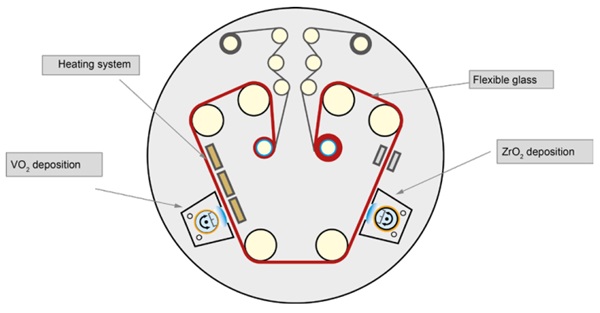

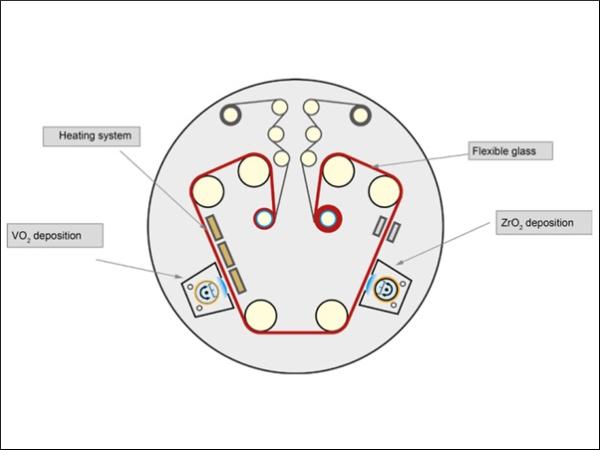

The work was carried out in the roll to roll coater (VON ARDENNE) depicted in figure 1.

A thin foil of flexible glass (300mm wide, 0.1 mm thick, NEG) was conveyed through the machine. At least two passes had been necessary to obtain the complete ZrO2 -VO2 -ZrO2 stack. During its way the foil passes two coating positions, both equipped with a rotatable magnetron (target length 650 mm). The right sputtering position was equipped with a ZrOx ceramic target (GfE Fremat). It was sputtered with a power of 6 kW. Adding 6 sccm of oxygen lead to the formation of a stoichiometric ZrO2 layer

The left position was used for the reactive sputtering of vanadium oxide. The metallic vanadium target (GfE Fremat) contained 1.2 at % of tungsten. This is necessary to shift the switching temperature to ambient conditions. High energy impulse magnetron sputtering (HIPIMS) was applied for this process (power supply: Nano4Energy). The power was 6 kW. The oxygen flow was roughly 25 sccm for the formation of VO2 layers of the correct crystallographic structure. The stabilization of the process was achieved by a feedback loop for the oxygen inlet, combined with a careful inline monitoring of the achieved results. A radiative heater behind the substrate increased to temperature of the flexible glass to approximately 350 degrees C at the start of the vanadium oxide deposition process. This value was determined by applying a model for the radiative heat exchange of the glass foil with its surroundings. The thermal conductivity of the foil can be neglected for this estimation.

Result

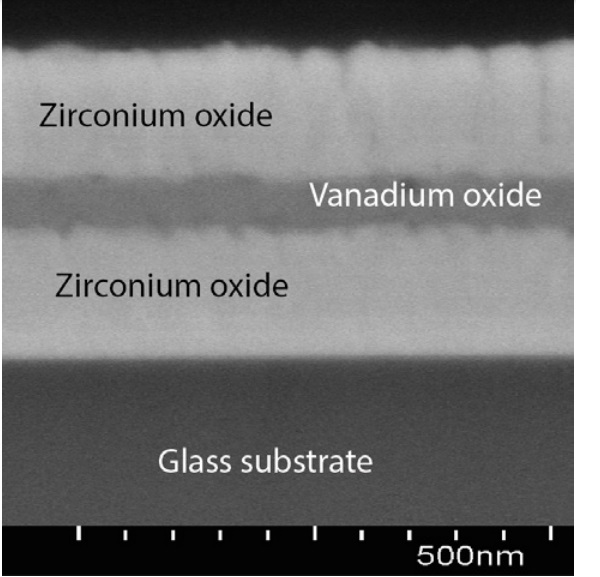

The SEM image of the complete layer stack is shown in figure 2.

The particular thicknesses are 70 nm for the VO2 layer, and 170 nm for the top and bottom ZrO2 -layers, respectively.

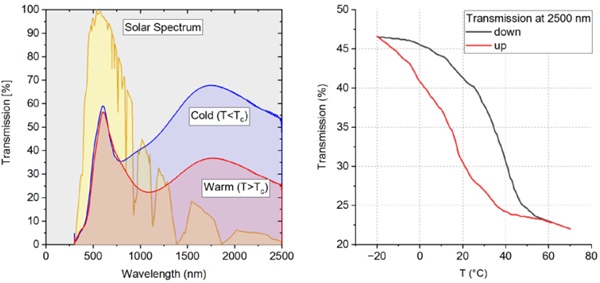

The transmission spectra in the two switching states are shown in Figure 3.

The optical properties in the visible spectral range remain nearly constant. In the near infrared spectral range one can distinguish a high temperature phase with low transmission and a low temperature phase with high transmission.

Acknowledgment

The work was supported by the European Committing Horizon 2020 program (project acronym: Switch2Save, GA number: 869929).

References

[1] https://www.irbnet.de/daten/iconda/CIB_DC26383.pdf

[2] M. Waewickm R. Binions ; j: Mater.Chem. A 2014, 2, 3275

[3] J. Vlcek et al., 2017 J. Phys. D: Appl. Phys. 50 38LT01

[4] J. Rezek, J. Szelwicka, J. Vlcek, R. Cerstvy, J. Houska, M. Fahland. J. Fahlteich; Surface and Coatings Technology, Volume 442, 25 July 2022, 128273

Comments

This article specifically focuses on thermochromic materials, which are just one type of smart coating among many others like gasochromic or photochromic coatings.

This paper presents a promising advancement in smart window technology through the roll-to-roll deposition of thermochromic vanadium oxide on flexible glass. Mars Planet Barber Shop