Authors: Abdultawab M. Qahtan & Abdulkarem H. M. Almawgani

Source: Buildings 2022, 12(8), 1249; https://doi.org/10.3390/buildings12081249

Abstract

Designing windows in hot climates that allow occupants to easily control their preferences in a smart home is of considerable importance. This paper aims to contribute to this topic by examining the potential of a smart window system that has double dynamic insulated glazing (DDIG) in preventing heat gain and maximising daylight indoors, considering smart privacy protection during both the day and the night. A small-scale model was developed to examine the proposed window system. Test cell temperature, glass surface temperature and indoor illumination lux were investigated.

The results showed that the DDIG had high solar heat control inside the test cell, with a significant reduction of 2.5 °C compared with the common glazing of translucent glass used in Najran City, Saudi Arabia. At high solar irradiation intensities, no significant differences in controlling the heat gain to the test cell were found between coloured DDIG (DDIG-colo) and transparent DDIG (DDIG-trans). A graded reduction between DDIG-trans and DDIG-colo was found with decreasing solar intensity, which was found to be 15%, 10% and 8.7% at irradiation intensities of 200, 400 and 600 W/m², respectively. The DDIG transparencies maintained the illumination lux with higher reduction under low solar irradiation. The DDIG also provided privacy protection and granted user preferences for outdoor connections.

1. Introduction

The careful design of windows in buildings provides sufficient energy savings [1] and appropriate visual comfort for occupants [2]. In hot climates, compared to walls, windows are a major source of heat gain [3,4]. Window energy efficiency is primarily obtained by designing windows to control solar heat gain [1]. Controlling solar heat gain through window glazing can be done in two ways. The first is to block direct solar radiation, which passes through the window glazing as short-wave radiation and then forms a greenhouse effect in the closed environment [5]. This approach can be controlled by window shading [6].

The second way is to reduce heat (long-wave IR) flow through windows, which is determined by the air temperature difference between indoors and outdoors [7]. Here, reducing the emissivity of glass surfaces is a choice and can be obtained by heat reflective coatings [8]. However, in hot arid climates, controlling heat gain by conventional window glazing is challenging. Reviewing the market of Najran City, Saudi Arabia, where this study was conducted, showed that typical window glazings used in residential buildings are translucent glass (pinhead glass PG that mainly used for privacy purposes) and tinted glass. Achieving privacy with translucent glass has many negative aspects, such as minimal heat gain control and inflexibility with the outdoor view and connection.

Tinted glass comes in several colours (bronze, green and grey) and has less U-value in comparison with translucent of PG. In hot arid climates, the main drawback of tinted glass is that it absorbs a large amount of infrared (IR) radiation. In the hot summer climate of Najran, where outdoor air temperatures can peak at 43 °C [9], long-wave IR (heat) increases the surface temperature of tinted glazing, which is eventually transmitted indoors [4]. Tinted glazing also causes a reduction of visible light depending on the degree of tint [10,11], window orientation and season [12].

Heat-reflective low-emissivity glass is the preferred choice for high outdoor air temperature environments due to its ability to reflect thermal energy into surrounding space [13]. That is, if the surface faces outward, then the heat is released to the outside of the building. To maintain the durability of the low-e coating, a double glazing with vacuum must be used [14]. In the hot climate, a low-e coat must be applied at the intermediate and outer pane of the double glazing to protect the indoors from thermal radiation [15]. This double low-e coat also needs to be integrated with tinted glass to reduce optical direct solar heat gain [16].

However, this tint causes low-e glass to reduce daylight illumination indoors and has no flexibility to respond to different times of the day and weather. In particular, it cannot easily provide privacy protection at night. Thus, a smart and dynamic tint (film) integrated with a double low-e clear glazing is needed. This is particularly important for residential buildings in conservative societies, where window glazing requires a careful selection to enhance the well-being of tenants by providing an acceptable view of the outside [17] without decreasing privacy protection.

A window for day and night privacy in residential buildings is important for comfort. Typical solutions for obtaining privacy include blinds and shades; however, have limitations. For example, they make a space dark and reduce outdoor connection. On the other hand, coloured and tinted glazing can enhance home privacy during the day but does not provide privacy at night. It also reduces daylighting during the daytime [10,11]. Currently, window glazing does not exist on the market that can provide both privacy and outdoor connection during the day and night.

In this context, a unique solution is a window system that incorporates smart and dynamic glass. The most popular types of smart glass include electrochromic (EC) and polymer dispersed liquid crystal (PDLC). These types of smart glass with electrical signals can permit higher daylight transmission in both states of transparent and translucent [18]. They also decrease solar radiation transmittance without the need for shading devices, such as blinds [19], and can also be used for privacy protection [20]. There are some drawbacks to using EC, including slow switching speed and high production costs [21]. However, PDLC is the most economical smart glass [22] and has a fast response speed with a colouring rate of 1 s or less [23].

Several studies have been conducted in relation to window glazings with a PDLC film. Hemaida et al. [24] investigated the effect of PDLC windows on the overall office building energy performance utilising a simulation program under two contrasting climate zones: an arid climate (Riyadh, Saudi Arabia) and a temperate climate (London, United Kingdom). They concluded that the PDLC window was more effective with a cooling reduction of 12.8% (arid climate) than a heating reduction of 4.9% (temperate climate). They also found that the PDLC provided excellent interior illuminance in both climates.

In another study, Hemaida et al. [22] examined the optical and thermal performance of a PDLC glazing system for the translucent and transparent states. A small-scale test cell equipped with PDLC glazing was exposed to solar irradiations of 1000, 800, 600 and 40 W/m² for 3 h. The major finding was that the PDLC glazing system showed effective thermal performance for heating in a cold climate, with Solar Heat Gain Coefficient SHGC values of 0.68 for the transparent and 0.63 for translucent states. Ghosh and Mallick [25] attempted to find the optical characteristics of PDLC glazing for building applications.

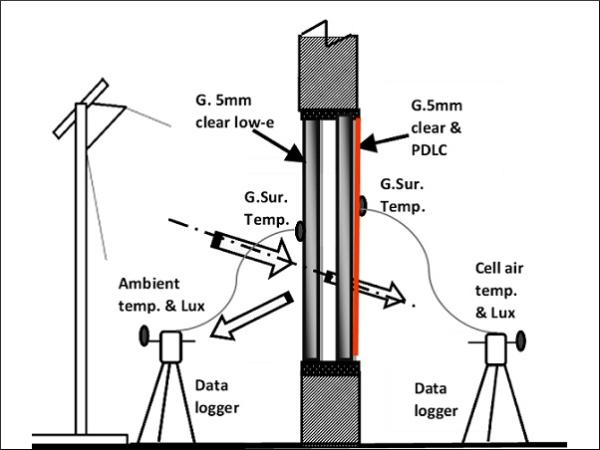

They found that the PDLC-transparent state offered a solar radiation (wavelengths ranging from 300–2500 nm) transmission of 41%, while that of the translucent state was 23%. Oh et al. [26] assessed the optical properties of four types of PDLC films and concluded that PDLC film reduced annual building energy consumption and improved daylight performance while considering glare prevention, which is the most basic function of shading devices. Table 1 summarises the previous studies conducted on the thermal and lighting properties of PDLC in the transparent and translucent states.

Table 1. Thermal and lighting properties of PDLC glazing.

In summary, in the smart home concept, one of the key supporting features is the ability to monitor the dynamic changes of solar radiation and then use smart windows to operate in energy-efficient ways [27,28]. This study aims to investigate the potential of a smart window system that has double dynamic insulated glazing (DDIG) in preventing heat gain and maximising natural light indoors without sacrificing home privacy protection during the day and night. Thus, the study proposes a DDIG system, namely double glazing with a low-e coating on the inner surface of the outer glass pane, combined with a PDLC switchable film on the inner surface of the second glass pane. The significance of this study is that the proposed system helps improve thermal and visual performance and provides dynamic privacy protection for residential buildings.

2. Methodology

The basic experimental methods capable of evaluating building performance are small-scale experimental models, full-scale models, analytical models and simulation models [29]. However, the small-scale model is an experimental technique to collect data on the effects of new materials and newly designed elements in building envelopes [30]. Even though the thermal and lighting performance may not be the same as that in the actual room under outdoor conditions, there are several advantages to using this method. For instance, it is much more economical [29], easily adaptable and provides experimental data that can be used in modelling and computer simulations.

To investigate the proposed glazing system of a DDIG system, laboratory experiments were designed utilising a small-scale model, as well as various materials and equipment. The following paragraphs describe the DDIG system, the equipment used to examine the effect of the DDIG system on thermal performance and illumination lux inside the test cell and the system’s capability to provide home privacy protection.

2.1. Test Cell, Glazing System and Instrumentations

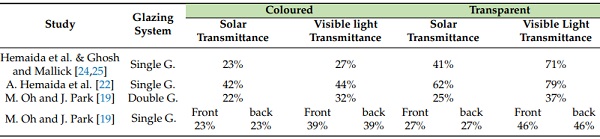

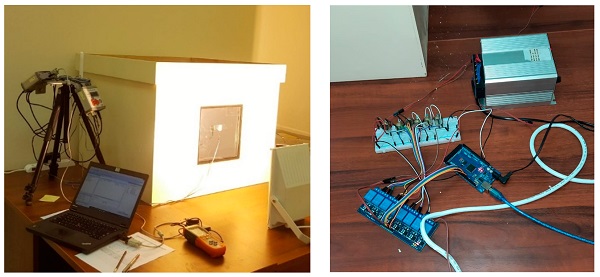

Measurements were conducted in a small-scale environmental test cell that was 80 cm wide, 80 cm deep and 60 cm high, as shown in Figure 1. The test cell was constructed from the outside to the inside (18 mm plywood + 10 mm ARNON insulation +6 mm plywood). The test cell was built in double walls with a gap of 10 cm at the two side walls and 20 cm at the back wall, forming inside dimensions of 60 L × 60 W × 60 H to a representative cubic unfurnished room of the scale model (1:5). The double walls provided more insulation and created a safe cavity for a datalogger. All the internal walls of the cell were coloured with white paint.

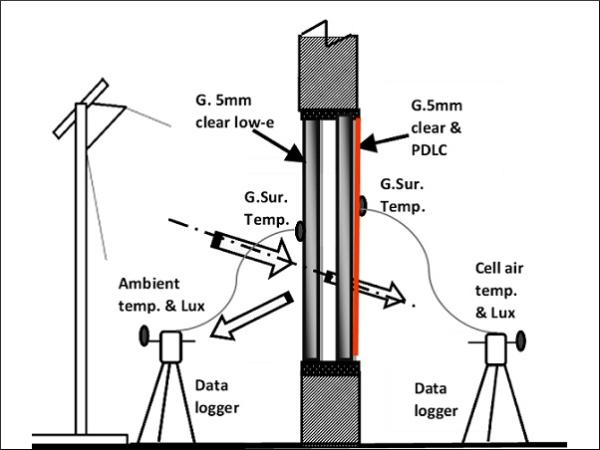

The front wall (60 cm wide), which had a window of 30 cm × 30 cm, resulted in a 25% WWR, which is 5% more than that recommended by the Saudi Building Code of 20% WWR [31]. This is because the sellers provide glazing samples limited to 30 cm × 30 cm. The DDIG was constructed specifically for this study by the HUAKE TEK Industry (5 mm clear low-e glass + 12 mm air gap + PDLC film + 5 mm clear tempered glass), as shown in Figure 1. The PDLC film integrated into a double low-e glass can be controlled either by the user or automatically by the external environment (outside air temperature, external solar radiation, external illuminance). The optical properties of the PDLC were discussed earlier as a summary of several previous studies (Table 1).

The test cell was equipped with surface temperature, air temperature and lux sensors to measure its performance through the DDIG. An LSI R-Log data logger was used to measure air temperature inside the test cell and ambient (lab room), glass surface inner and outer temperature and illumination lux inside the test cell. An Extech Infrared Thermometer was used at the beginning of the test to reduce measurement uncertainty. A BH1750FVI sensor was attached to the front wall side of the window and connected to an Arduino for smart control of the DDIG transparencies. Table 2 includes information about the sensors and their accuracies.

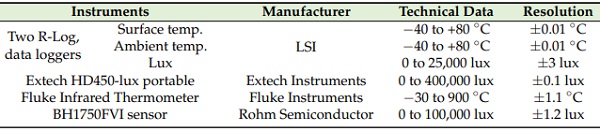

Table 2. Technical characterization of the sensors and their accuracies.

2.2. Solar Simulator

Solar simulators are used in laboratory experiments with a scaled-down building space to test factors affecting buildings under controlled conditions. Solar simulator systems are costly, but a low-cost solar simulator can be designed using several types of lamps that cover the entire irradiation wavelength range. Given that this study investigates the thermal and illumination performance of a window system, it benefits from the advancements of metal halide lamps with a good spectral match to the solar output ranging from 200 nm to well past 2500 nm, and temperatures ranging from 5000 K to 6000 K (almost similar to the 5800 K of the surface of the sun) [32,33,34]. The present study was designed a solar simulator using an Osram warm-white metal halide lamp with a power of 150 W and a temperature of 4000 K.

The measurements used an Arduino to switch the simulator lamp on and off. The solar irradiation was simulated by varying the brightness of the metal halide lamp by adjusting the distance from the window system. The solar irradiation value was confirmed using an Extech HD 450 lux meter that measures from 0.0 to 400 Klux, with a basic accuracy of ±5%. The Illuminance lux to solar irradiation conversion factor was 1 W/m², equalling 116 for artificial light of solar simulators and 120 for outdoor natural sunlight [35]. A digital light sensor BH1750FVI was attached to a side of the outer skin of the glazing system and connected to the Arduino to control the DDIG transparency according to the experiment schedule, which comprised 60 or 120 min exposure at each of the eight different transparencies and 120 min rest between each case.

2.3. Dynamic Setpoint Control Operation

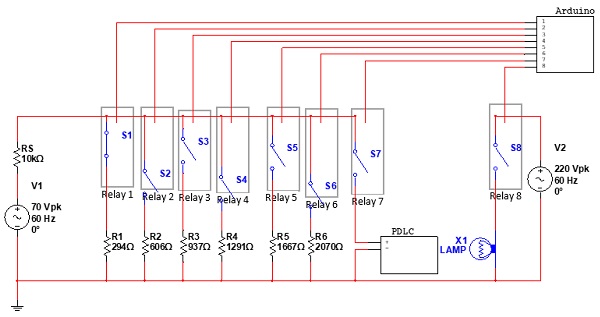

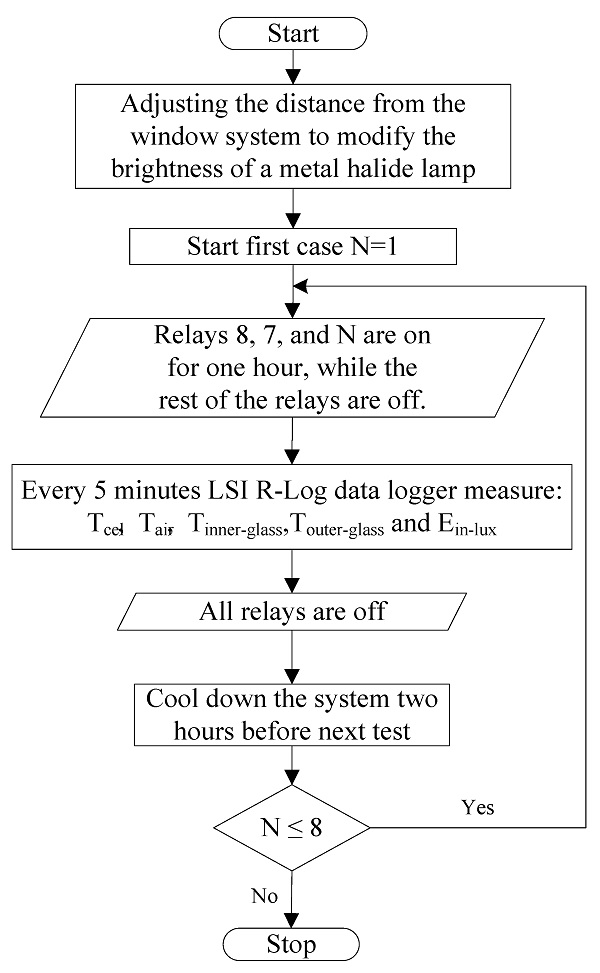

The Arduino adjusted the PDLC glass’s transparency percentage according to the dynamic setpoint control operation. Every case of operation lasted for 60 min (in some cases, 120 min), followed by 120 min of switching off to cool down the system. Figure 2 depicts the proposed circuit diagram, which clarifies all the electrical circuit components.

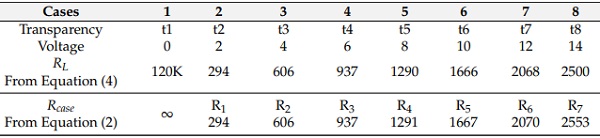

Table 3 shows the calculation of the resistances (Rcase and RL) in various transparency cases. The resistors provide the appropriate voltage for the appropriate gradient as follows:

Table 3. Resistance measurement in different transparency cases.

The voltage varied from 2 V to 14 V, with seven cases to provide the seven needed transparencies of the proposed PDLC system.

The resistance of PDLC was measured, where RPDLC = 120 kΩ and Rs was assumed to be 10 kΩ.

Resistance on the load consists of two parallel resistances.

The value of the state resistance can be derived from Equation (1), and the result is as follows:

The voltage on the PDLC according to the voltage divider is given:

The various load resistances in different cases from Equation (3) can be derived as follows:

Equation (1) was used to calculate the resistances in each case. We assumed that the seven scenarios in Table 3 with seven voltages ranging from 2 to 14 volts produced distinct gradations on the PDLC film. In each situation, the total load resistance can be calculated, and a value can be substituted in Equation (2) to calculate Rcase.

Table 3 shows no difference between the load resistance and the case resistance. The reason for this result is that the load resistance comprised two parallel resistances, one of which was the film resistance, which had a very high value compared to the case resistance. According to mathematical laws, the sum of two parallel resistances, in which the first is very small and the second is very large, equals an approximation of the small one.

Figure 3 depicts the proposed DDIG system flowchart of the workflow:

- Metal halide lamp brightness could be adjusted by varying the distance from the window system.

- For 60 min, relays 8, 7 and N were on, while the rest of the relays were off.

- All relays were turned off for 120 min to allow the system to cool down before the next test.

- An LSI R-Log data logger was used to measure air temperature inside the test cell Tcel and ambient (lab room) Tair, glass surfaces inner Tinner-glass and outer temperature Touter-glass, and illumination lux inside the test cell Ein-lux.

- Steps 2–4 were repeated six times to complete the six separate transparency situations.

2.4. Double Dynamic Insulated Glazing System, DDIG

To form a unique dynamic insulated glazing system for residential buildings in hot climates, the double glazing with PDLC switchable film was applied on the inner surface facing the test-cell environment, combined with an outer panel with a low-e coat applied on the inner surface facing the cavity. Dynamic transparencies were chosen to cope with dynamic solar radiation during the day. This technology also provided the flexibility to switch to a transparent state for providing an outdoor connection in the daytime and to switch to a coloured state for privacy protection at night.

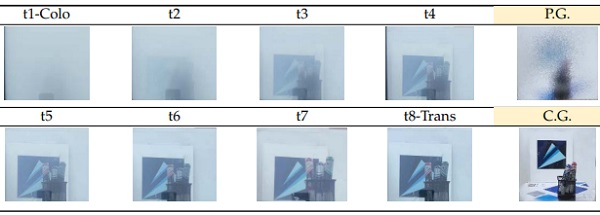

To attain different transparencies of DDIG, a different voltage could be applied to the inner skin of the system, which had a PDLC film using an Arduino with a stepping voltage of 2 V to 14 V to obtain different transparency levels. Table 4 demonstrates the DDIG with different transparencies of PDLC film, starting with the coloured state (t1-colo), followed by t2 to t7 and ending with the transparent state (t8-trans). The photographs in Table 4 were taken when the two sides of the DDIG were exposed to the same light intensity.

Table 4. Photographs of different DDIG transparencies compared to 6 mm pinhead and clear glass. Both sides were exposed to the same illumination.

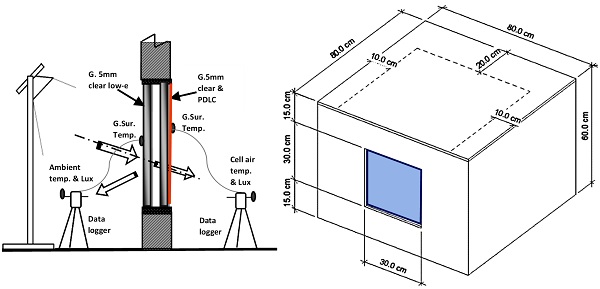

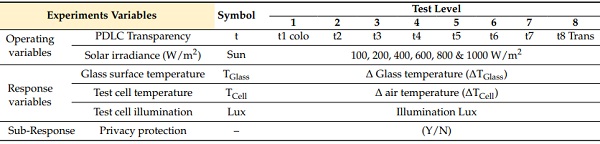

Table 5 summarises the design of experiments with the two design parameters, namely DDIG transparency and solar radiation intensity involving 6 × 8 = 48 tests. The dynamic transparency of DDIG was controlled by an Arduino, providing eight gradient transparencies. These two design parameters were investigated for three response parameters, namely glazing surface temperature, test cell air temperature and illumination lux in the test cell. Figure 4 shows a photograph of the experimental setup used to evaluate the proposed DDIG system.

Table 5. Design of the experiments, 48 cases.

3. Results and Discussion

3.1. Comparative Evaluations-Baseline

The experiments in this study started with a preliminary investigation to compare the commonly used single PG window glazing in residential buildings of Najran against the double insulated (low-e) glazing DIG system. Starting the experiments by comparing Clear Glass CG and PG against DIG (that is, the baseline of the proposed DDIG system) provided a clearer picture of the reliability of the experiments and measurements due to the large differences in the values. Comparisons were performed based on the differences in outdoor/indoor air temperature and glass surfaces, in addition to the lux inside the test cell.

Figure 5 shows that the test cell was exposed to solar irradiance of 800 W/m2, and the ambient temperature (lab room) remained between 28.1 and 28.8 °C as the air conditioning was kept off during the period of experiments. Other factors, such as air velocity and relative humidity in the laboratory room, were considered constant and negligible, as no changes occurred to the lab room ambient during the experiment period.

Figure 5 compares the air temperature and glass surface temperature of CG, PG, DIG and DDIG-trans under solar irradiation of 800 W/m2, which corresponds to the maximum value on horizontal surfaces for sunny days in summer in Saudi Arabia [36]. Comparing the temperature inside the test cell showed that PG performed better than CG, with a small difference of 0.5 °C following a 60 min exposure to the solar simulator lamp. Within this short test duration, DIG significantly contributed to controlling heat gain indoors, with a reduction of 2.2 °C compared with PG. Applying PDLC film in its transparent state to the inner skin of DIG (DDIG-trans) resulted in a slight improvement (less than 0.5 °C) in controlling the solar heat gain inward compared with the baseline of DIG.

Figure 5 also shows that the inner surface temperature of DIG reached 38 °C with a reduction of about 17 °C compared with the common PG, which has an inner surface temperature of about 55 °C. An increase in the inner surface temperature of about 3.3 °C in the plot of DDIG-trans compared with the inner glass of DIG can be attributed to the spectral data of the PDLC film on the inner skin of DDIG, which has more solar energy absorption compared with the clear glass of the DIG.

A preliminary investigation was conducted on the performance of the proposed glazing system (DDIG) at its transparent state (DDIG-trans) compared to the PG and DIG, which are used in residential buildings with different percentages of use. DIG was found to be the least used due to its high cost. However, the use of DIG also has disadvantages from its use of colour (tinted glass), which reduces light transmission and limits clear outdoor connection and resident privacy, particularly at night. However, after exploring the thermal and light performance of the proposed DDIG system, the following sections provide extensive experiments and discussion on the dynamic transparencies of DDIG to match the dynamic solar radiation and day/nighttime.

3.2. Dynamic Transparency of DDIG with Accordance to Dynamics of Solar Radiation

Solar radiation varies during the day and on different facades and building orientations. These variations require the design of dynamic windows that provide shading in times of high solar intensity in summer, enable the choice of increased daylighting and outdoor connection at times of lower solar radiation and consider the smart privacy protection of users from exposure to the outside. The proposed DDIG window system, which incorporates a low-e coating and dynamic shading of PDLC film, was examined under different solar irradiation intensities with different transparencies.

3.2.1. Thermal Performance of Various Transparencies of the DDIG System

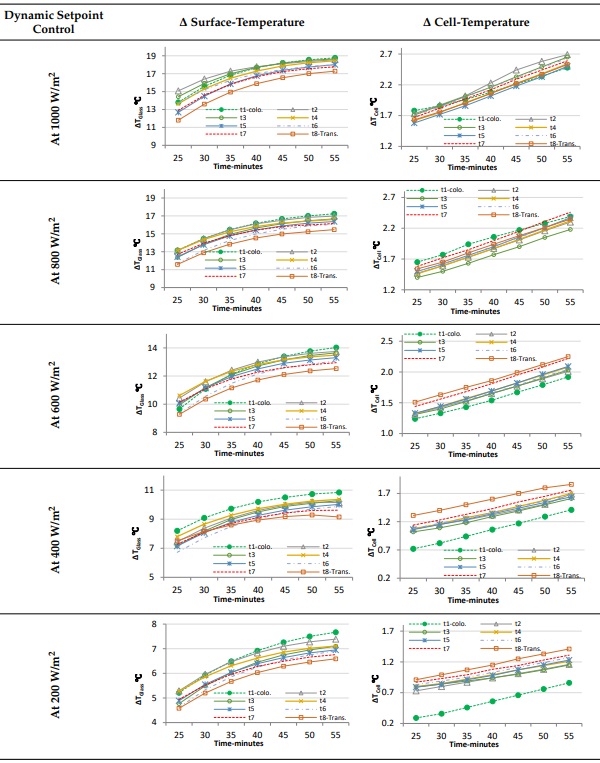

The extensive experiments ran 48 cases (Table 5). Eight different transparencies of DDIG (t1–t8) were exposed to a constant indoor solar simulator at different irradiation intensities (namely 1000, 800, 600, 400 and 200 W/m2) for 60 min exposure times. The temperature outside the test cell, that is, the temperature of the laboratory, remained between 28.1 and 28.8 °C. The results are plotted and demonstrated in Table 6 and discussed as follows:

Table 6. Dynamic transparency of the DDIG as a function of various solar irradiation intensities.

- Under the irradiation of 1000 W/m² (see row 1 of Table 6), the temperature differences (∆TCell and ∆TGlass) of the DDIG system with eight transparencies (t1 to t8) are illustrated. After 60 min exposure to the sun simulator lamp, the glass surface temperature differences (∆TGlass) varied between 17.3 and 18.8 °C at t8-trans and t1-colo, respectively, corresponding to a gap difference of about 1.5 °C between the two transparencies. Negligible variations were found in the remaining transparencies (from t3 to t6). However, a low-e coat on the inner surface of the outer glass pane reduced the conduction heat gain, which caused a lower temperature of the internal glass. In addition, the coloured state of the PDLC film on the internal glass of the DDIG system reflected a portion of solar irradiance toward the outer glass pane, increasing its surface temperature compared to the surface temperature of the internal glass pane. By contrast, air temperature differences (∆TCell) between the test cell and the ambient environment remained almost the same at all transparencies, with a temperature difference of about 2.7 °C. This was found at t1-colo, marking a temperature difference slightly higher than that found at t8-trans (about 2.5 °C) following 60 min exposure to the solar simulator lamp. The greater this difference, the higher the rate of heat gain. DDIG, in its transparent state at 1000 W/m², caused an increase in heat gain of about 12% compared with the coloured state. Hence, t1-colo is preferred because of the lower temperature difference between the test cell and the ambient.

- Under the irradiation of 800 W/m² (see row 2 of Table 6), the glass surface temperature differences varied between 15.5 and 17.2 °C at t8-trans and t1-colo, respectively, corresponding to a gap difference of about 1.7 °C between the two transparencies. The temperature variation between the ambient and test cell ranged from 2.1 °C at t1-colo to 2.4 °C at t8-trans, indicating a 12% difference in favour of t1-colo. DDIG performed similarly under high solar intensities of 1000 and 800 W/m² in both the transparent state and coloured state due to low solar reflection and control in both states.

- Under the irradiation of 600 W/m² (see row 3 of Table 6), the glass surface temperature differences varied between 12.9 and 14.4 °C at t8-trans and t1-colo, respectively, corresponding to a gap difference of about 1.5 °C between the two transparencies. In terms of air temperature variation, the plots show that the differences had a higher gap between t1-colo and t8-trans compared with that at 1000 and 800 W/m². Given that a lower difference is preferred, t1-colo is more efficient in controlling heat transmission inward. The temperature difference was found to be about 1.9 °C, which was less than the 2.3 °C at t8-trans, indicating a 17.4% difference in favour of t1-coloured.

- Under the irradiation of 400 W/m² (see row 4 of Table 6), the glass surface temperature differences varied between 9.2 and 10.8 °C at t8-trans and t1-colo, respectively, corresponding to a gap difference of about 1.6 °C between the two transparencies. The plots show that the differences between the ambient environment and the test cell had a clear temperature variation between the case of t1-colo and the case of t8-trans. The lower difference was found at t1-colo with a temperature difference of 1.4 °C compared with 1.9 °C at t8-trans, indicating a 20.3% difference in favour of t1-colo.

- Under the irradiation of 200 W/m² (see row 5 of Table 6), the plots show the differences in grading in accordance with the changes in the transparency of DDIG. Eliminating the overlapping curves, the lower air temperature difference between ambient and test cell of about 0.9 °C was found at t1-colo, compared with an air temperature difference of about 1.4 °C at t8-trans following 60 min of exposure. This result indicates a 35.7% difference between the two cases in favour of t1-colo.

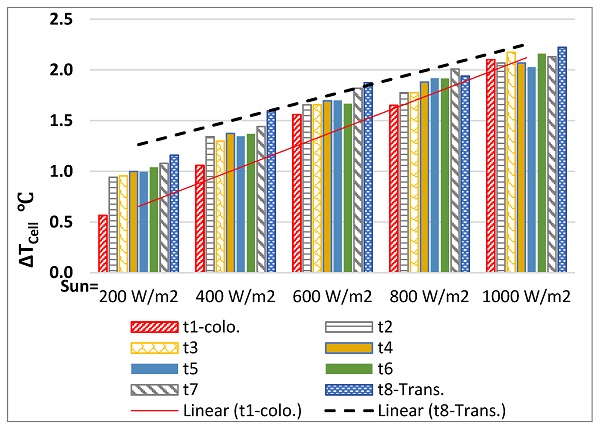

Figure 6 summarises the results, comparing the temperature differences between the test cell and the ambient environment. The values provided are an average of 60 min exposure times to the solar simulator lamp for the 48 cases. A minor difference in the indoor air temperature (less heat gain control) with all transparencies of DDIG was found under high solar irradiations of 1000 and 800 W/m².

An improvement in the DDIG’s capability to reduce heat gain was found to be inversely proportional to the intensity of the solar radiation, where the efficiency of the DDIG increased as the solar radiation decreased. Furthermore, the examined transparencies (particularly t4, t5 and t6) had no significant variation in controlling heat gain to the test cell space under all solar radiation intensities. The linear plots in Figure 6 show that coloured-DDIG had better heat control under low solar irradiation than that under high solar irradiation.

3.2.2. Validation of DDIG Thermal Performance of Both Cases: Coloured and Transparent

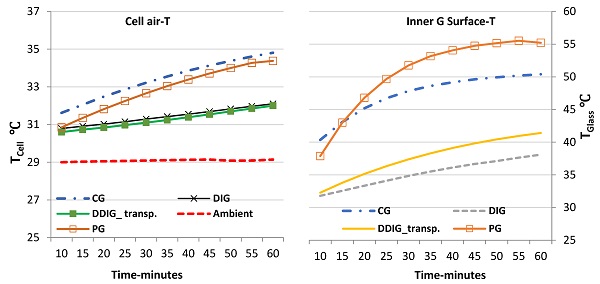

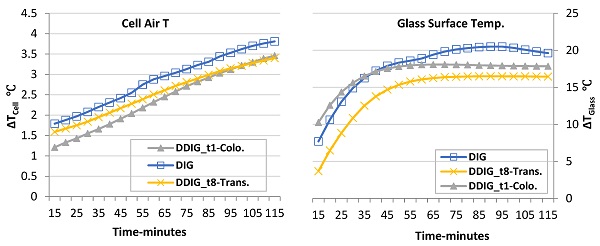

The above results showed that at high solar irradiation (e.g., 800 W/m²), no significant differences were found between the t1-colo and t8-trans states in controlling the inward heat transmission. For further discussion and to confirm these results, the study repeated the experiment by increasing the exposure time to 120 min for each case. Figure 7 compares the reference case of the DIG (double glass with low-e coat applied to inner glass of outer pane) with the proposed DDIG system in its two states: the transparent state (DDIG_t8-trans.) and the coloured state (DDIG_t1-colo.).

The left side of Figure 7 compares air temperature differences between ambient (lab room) and inside the test cell. Under the irradiation intensity of 800 W/m², air temperature differences between the DIG, transparent-DDIG and coloured-DDIG were found to be 3.8, 3.7 and 3.4 °C, respectively. A lower difference indicates better performance and greater heat gain control. Therefore, no serious differences occurred between these cases in controlling heat gain, with a small preference for the coloured-DDIG (t1-colo.) confirming the results in Figure 6 and Table 6. These results agree with those recorded by the authors of [26], who conducted PDLC spectrum analysis and found that solar transmittance was reduced by 15.8% in the coloured state compared with the transparent state.

Furthermore, our results agree with those reported by the authors of [24], where the coloured state of PDLC achieved an annual energy reduction of 12.8% in the hot arid climate of Riyadh, Saudi Arabia. By contrast, the result found by the authors of [22] concludes that coloured-PDLC applied to single glazing increased heat gain compared with its transparent state. However, the improvement in controlling heat transfer in the present study can be attributed to the integration of PDLC film with insulated glazing of low-e in a double window that formed the proposed DDIG system.

In terms of glass surface temperature with 120 min exposure to the solar simulator lamp, Figure 7 shows a rapid increase in the temperature differences of glazing surfaces of the DDIG. After 75 min, the temperature differences began to settle and were maintained at approximately equal values in both states, namely the transparent and coloured states. The baseline of the DIG showed a different response, where the glass surface temperature continued to increase as the window system was exposed to the lamp of the solar simulator. This indicated the advantage of the DDIG in controlling heat gain compared with the reference window of the DIG.

Figure 7 also shows that the differences between the outer and inner glass surface temperatures of DIG, transparent-DDIG and coloured-DDIG were 19.6, 16.5 and 17.9 °C, respectively. Notably, a lower difference was found at the transparent-DDIG under the irradiation of 800 W/m². Following 120 min of exposure, the outer glass of transparent-DDIG and coloured-DDIG had a surface temperature of about 60.3 and 60.9 °C, respectively, while the inner surface temperature was 43.8 °C and 43.0 °C, respectively.

However, the inner glass surface temperature of the DDIG remained lower than that of the outer one, causing lower heat energy transmission inward. This finding is in disagreement with the results found by the authors of [22], where the inner glass surface temperature was higher than that of the outer glass surface, causing heat to flow inward. The improvement of the proposed DDIG can be attributed to its double glazing, which uses insulated low-e glass as the first skin and PDLC as the second.

3.3. Lighting Transmission and Illumination Lux with the DDIG System

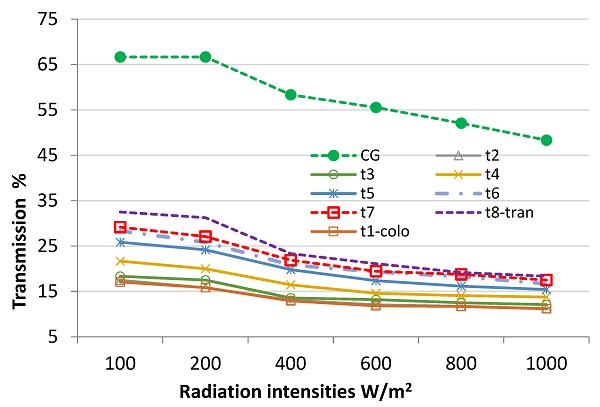

Light transmission and test cell illumination were examined to understand how each case performs in comparison. In relation to indoor illuminance, the study aimed to determine how well a DDIG system with a variety of transparencies could transmit light into the test cell under different solar simulator irradiances of 100 W/m² to 1000 W/m².

The light transmission was measured on the test cell (field measure) using two lux meters that were attached to both sides of the DDIG system. One of the lux meters was vertically attached to the outer skin of the outer glass pane, facing the solar simulator lamp. At the same time, the second lux meter was vertically located at the back of the inner glass surface that faced the inside of the test-cell to measure the amount of light that passes through the DDIG. Due to the haze of the DDIG-colo, the light transmits at more angles than a sample that is not hazy. However, for an accurate reading, the lux meter was placed 5 cm past the inner skin.

A clear float glass of 6mm was used to validate the results of testing the light transmission. Thus, the light transmission was calculated for the DDIG system using the following equation.

where I = transmitted light measured on the inner glass of the DDIG and Io = incident light on the outer glass of the DDIG.

Figure 8 shows the light transmissions of the DDIG system. The average light transmission for all solar irradiance was 58%, 24% and 13% for the 6mm clear glass, transparent (t8-trans) and coloured (t1-colo) state, respectively. During the low solar irradiance from 100 to 200 W/m², the DDIG offered higher light transmission of 32.5% at t8-trans compared to 17% at t1-colo. This variation indicates that under low solar irradiance, DDIG-t1-colo was able to provide light indoors in addition to glare control.

Under the high solar irradiance from 600 to 1000 W/m², the light transmission varied between 18% and 11% at t8-trans and t1-colo, respectively. With direct observation, indoor privacy protection can be achieved with the range of t1-colo to t4, with average light transmission varying between 13 and 16%, respectively. However, previous studies reported that the PDLC haze coefficient of t1-colo was 71.4% and t8 was 6.4% [22].

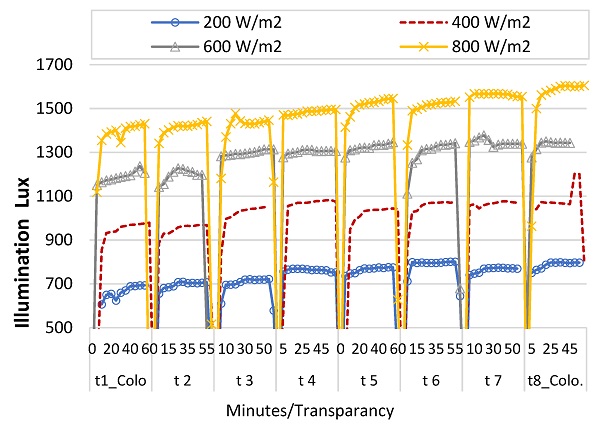

In terms of the illumination performance inside the test cell with the proposed DDIG system, the measurements were taken at 150mm height in the centre of the test cell. The results are a function of different solar irradiations and different DDIG transparencies. Figure 9 shows that the illumination lux gradually increased with the increment of DDIG transparency. For instance, the illumination inside the test cell at 800 W/m² increased from 1430 lux at t1-colo to 1605 lux at t8-trans, an increase of about 10%. Likewise, under the low solar irradiation of 200 W/m², an increase of about 15% in illumination lux was found from 690 lux with t1-colo to 795 lux with t8-trans. The dynamic transparencies of the DDIG showed more control of the illumination lux inside the test cell under low solar irradiation than that under high solar irradiation.

Thus, the dynamic transparencies of the DDIG better maintained indoor illumination lux (daylighting) under diffused daylighting than that under direct sunlight. However, the DDIG still provided privacy protection and may provide daylight glare-control (by controlling direct sunlight). When comparing the coloured state of the DDIG (t1-colo) to the common PG, a high illumination lux reduction occurred, with an average of about 60% lower under the DDIG at solar irradiations between 400 W/m² to and W/m². Under the coloured state of the DDIG, a more visible light shading contributed to more privacy protection, in addition to its effect on controlling thermal transmittance. The dynamic transparency of PDLC film integrated with low-e glazing as double glazing (DDIG system) provided the flexibility to respond to tenant desires according to dynamic solar radiation and home privacy protection throughout the day and night.

3.4. Optimum Transparency of the DDIG System for Homes in a Hot Climate

The significance of the dynamic transparencies of the proposed DDIG system to residential buildings in hot climates of Najran City is due to its capability in responding to dynamic solar radiation that contributes to daylight glare-control and reducing heat gain, particularly when compared with conventional glazing PG that is mostly used in residential buildings of Najran. The DDIG also provides dynamic privacy protection and grants an outdoor connection depending upon the outdoor conditions.

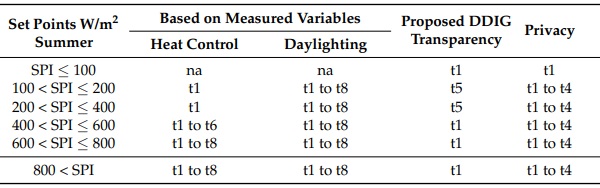

The concept responds to selected solar setpoints (100 W/m² to 1000 W/m²) matched with different transparencies of the DDIG (t1-colo to t8-trans). It works by the integration between two lux sensors located outside and inside the spaces, in addition to an outdoor solar radiation sensor. Based on the results discussed earlier, Table 7 summarises the optimum transparencies of the DDIG in relation to dynamic solar radiation, illumination lux and privacy protection. The optimum transparencies of the DDIG were concluded as follows.

Table 7. Proposed transparencies of the DDIG with accordance to external solar irradiance.

- The setpoint of solar irradiation of (≤100) W/m2 turned the transparency of the DDIG into t1-colo, knowing that the PDLC haze coefficient of t1-coloured was 71.4% and t8 was 6.4% [22]. However, the priority, in this case, was given to privacy protection as indoor lux was higher than outdoor lux (frequently, electrical lighting is switched on in the early morning and early evening).

- Under the solar irradiation of 100 < SPI ≤ 200 and 200 < SPI ≤ 400 W/m2, the selected transparency was also t1, which provides thermal reduction as shown in Figure 6. It was also suitable to choose t5 (with an approximate haze coefficient of 34%, considering that t1 was 71.4%). This choice provided enough light and enabled residents to see through from the inside out while still providing privacy protection because the outdoors is brighter.

- The t1-coloured state of the system under solar radiation is recommended to be within the range of 400 < SPI ≤ 600 W/m2 with priority given to heat control.

- Under high solar irradiation of 600 < SPI ≤ 800 W/m2 and 800 < SPI, the t1-coloured state of the system is recommended for daylight glare control, in addition to its contribution to a slight heat control compared with its transparent state.

- The transparency of t8-trans and t7 should be manually switched to provide an outdoor connection as needed.

- At night when tenants are inside the home and use electrical lighting, more light was being reflected inside than that coming from outside. Therefore, DDIG-t1-colo is the choice for maximum privacy protection.

3.5. Limitations of the Study

The DDIG system was examined with a variety of transparencies under different solar irradiances. However, it was difficult to maintain a particular outdoor solar irradiance from 100 W/m² to 1000 W/m² to examine the eight cases of DDIG (t1-colo to t8-trans) at each individual sun. To reduce the effects of the outdoor environmental conditions, a small-scale model was used to obtain accurate measurements of the solar heat gain, thermal performance and light transmission of the DDIG system in an indoor environment considering only the proposed glass system. This helped to draw dynamic transparency that matched control setpoints to optimize DDIG system performance. In addition, a small-scale model required low costs and space.

Moreover, a solar simulator was used in the present experiment to investigate variables under controlled and repeatable conditions. A metal halide lamp was used because it provides a good spectral match to the solar output, particularly for thermal applications. Its light sources are commercially available and do not require a complex and expensive power supply [32,37]. Metal halide lamps are limited providing a stable output, causing the appearance of some fluctuations in the results of this study, particularly at the start and end of each case. To overcome this weakness, the experiments were repeated by increasing the exposure time from 60 min to 120 min (as shown in Figure 7). The analysis excluded 5 min from the start and end of measurements where the lamp was unstable.

4. Conclusions and Recommendations

4.1. Thermal Performance of the Proposed DDIG Window System

- A significant contribution in controlling heat gain indoors was found in DDIG compared with the common translucent glazing of PG, which is mostly used in residential buildings of Najran, Saudi Arabia. A reduction of 2.5 °C inside the test cell occurred when replacing PG with the proposed DDIG system.

- An improvement in DDIG’s capability to reduce heat gain was found to be inversely proportional to the intensity of solar radiation, where the efficiency of the DDIG increased as the solar radiation decreased.

- At high solar radiation intensities, no significant differences were found between t1-colo and t8-trans. The remaining examined transparencies, particularly t4, t5 and t6, have no significant variation in controlling the heat gain to the test cell space under all solar radiation intensities. In terms of glazing surface temperature, the inner glass surface temperature of all transparencies of DDIG and under different solar radiation intensities remained lower than that of the outer one, causing lower heat energy transmission inward.

4.2. Optimum Transparencies with Solar Set Points

The concept was the response of different transparencies of DDIG (t1-colo to t8-trans) to selected solar setpoints (100 W/m² to 1000 W/m²). In general, the dynamic transparencies of the DDIG had no meaningful difference in controlling the heat gain inside the test cell.

- The t1-coloured state of the system is recommended for solar irradiations within the range of 100 W/m² for privacy protection, as well as for solar irradiations from 400 W/m² to 600 W/m² for heat control. At night when electrical lighting is switched on, DDIG-t1-colo is also recommended for maximum privacy protection.

- The transparency of t5 is recommended for solar irradiations of 200 W/m², which enables some privacy protection and an outdoor connection.

- The t1-coloured state is recommended for high solar irradiations of 800 W/m² and above, which enables solar heat control as well as daylight glare control.

- The transparency of t8-trans and t7 should be manually switched to provide an outdoor connection as needed.

4.3. In Terms of Indoor Illuminance

The coloured state of DDIG (t1-colo) reduced illumination lux at the work-plane of the test cell with an average of about 60% compared with translucent PG under all solar irradiation intensities from 400 W/m2 to 800 W/m2. The dynamic transparencies of the DDIG showed more control of the illumination lux inside the test cell under low solar radiation intensities than that under high solar radiation intensities. The average light transmission (lux meters were vertically attached to the both sides of DDIG) was 58%, 24% and 13% for the 6mm CG, DDIG-t8-trans and DDIG-t1-colo, respectively.

For further study: In the hot climate of Saudi Arabia, window design involves summer solar heat gain that is much more critical than heat loss in winter. However, future study will focus on a reversible window system of DDIG that has a low-e pane facing inward and a PDLC pane facing outward in winter, compared to the reverse order in summer.

The DDIG system might be improved by integrating triple glazing with double layers of PDLC film in between to increase the system capability in solar shading and to prevent the absorbed solar radiation from entering indoors. The results of this work will be beneficial for building engineers to incorporate in the retrofit or design of a new low-energy building with PDLC switchable double glazing.

Author Contributions

Conceptualization, A.M.Q. and A.H.M.A.; Investigation, A.M.Q. and A.H.M.A.; Methodology, A.M.Q. and A.H.M.A.; Software, A.H.M.A.; Writing the first draft, A.M.Q.; Visualization, A.M.Q. All authors have read and agreed to the published version of the manuscript.

Funding

The authors are thankful to the Deanship of Scientific Research at Najran University for funding this work under the General Research Funding program grant code (NU/-/SERC/10/562).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data used to support the findings of this study are available from the authors upon request.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Kaasalainen, T.; Mäkinen, A.; Lehtinen, T.; Moisio, M.; Vinha, J. Architectural window design and energy efficiency: Impacts on heating, cooling and lighting needs in Finnish climates. J. Build. Eng. 2020, 27, 100996. [Google Scholar] [CrossRef]

- Acosta, I.; Campano, M.Á.; Molina, J.F. Window design in architecture: Analysis of energy savings for lighting and visual comfort in residential spaces. Appl. Energy 2016, 168, 493–506. [Google Scholar] [CrossRef]

- Wu, H.; Wang, D.; Liu, Y.; Wang, Y. Study on the effect of building envelope on cooling load and life-cycle cost in low latitude and hot-humid climate. Procedia Eng. 2017, 205, 975–982. [Google Scholar] [CrossRef]

- Lu, S.; Li, Z.; Zhao, Q. Thermal Process of Windows in Hot Summer and Cold Winter Climate. Procedia Eng. 2015, 121, 1788–1794. [Google Scholar] [CrossRef]

- Santolini, E.; Pulvirenti, B.; Guidorzi, P.; Bovo, M.; Torreggiani, D.; Tassinari, P. Analysis of the effects of shading screens on the microclimate of greenhouses and glass facade buildings. Build. Environ. 2022, 211, 108691. [Google Scholar] [CrossRef]

- Ye, Y.; Xu, P.; Mao, J.; Ji, Y. Experimental study on the effectiveness of internal shading devices. Energy Build. 2016, 111, 154–163. [Google Scholar] [CrossRef]

- Qahtan, A.M. An Empirical Study on the Use of Water Film in Glazed Buildings to Reduce Solar Radiation Transmittance in the Tropics. J. Green Build. 2015, 10, 141–160. [Google Scholar] [CrossRef]

- Kou, R.; Zhong, Y.; Kim, J.; Wang, Q.; Wang, M.; Chen, R.; Qiao, Y. Elevating low-emissivity film for lower thermal transmittance. Energy Build. 2019, 193, 69–77. [Google Scholar] [CrossRef]

- Al-Tamimi, N.; Qahtan, A.; Abuelzein, O. Rear zone for energy efficiency in large mosques in Saudi Arabia. Energy Build. 2020, 223, 110148. [Google Scholar] [CrossRef]

- Tuchinda, C.; Srivannaboon, S.; Lim, H.W. Photoprotection by window glass, automobile glass, and sunglasses. J. Am. Acad. Dermatol. 2006, 54, 845–854. [Google Scholar] [CrossRef] [PubMed]

- Li, D.H.W.; Tsang, E.K.W. An analysis of daylighting performance for office buildings in Hong Kong. Build. Environ. 2008, 43, 1446–1458. [Google Scholar] [CrossRef]

- Kumar, G.K.; Babu, T.P.A. Study of Various Glass Materials to Provide Adequate Day Lighting in Office Buildings of Warm and Humid Climatic Zone in India. Energy Procedia 2017, 109, 181–189. [Google Scholar] [CrossRef]

- Schaefer, C.; Bräuer, G.; Szczyrbowski, J. Low emissivity coatings on architectural glass. Surf. Coat. Technol. 1997, 93, 37–45. [Google Scholar] [CrossRef]

- Somasundaram, S.; Thangavelu, S.R.; Chong, A. Effect of Existing Façade’s Construction and Orientation on the Performance of Low-E-Based Retrofit Double Glazing in Tropical Climate. Energies 2020, 13, 2016. [Google Scholar] [CrossRef]

- Jelle, B.P.; Kalnæs, S.E.; Gao, T. Low-emissivity materials for building applications: A state-of-the-art review and future research perspectives. Energy Build. 2015, 96, 329–356. [Google Scholar] [CrossRef]

- KiranKumar, G.; Saboor, S.; Babu, T.P.A. Investigation of Various Low Emissivity Glass Materials for Green Energy Building Construction in Indian Climatic Zones. Mater. Today Proc. 2017, 4, 8052–8058. [Google Scholar] [CrossRef]

- Kim, J.; Kent, M.; Kral, K.; Dogan, T. Seemo: A new tool for early design window view satisfaction evaluation in residential buildings. Build. Environ. 2022, 214, 108909. [Google Scholar] [CrossRef]

- Ghosh, A.; Norton, B.; Mallick, T.K. Daylight characteristics of a polymer dispersed liquid crystal switchable glazing. Sol. Energy Mater. Sol. Cells 2018, 174, 572–576. [Google Scholar] [CrossRef]

- Oh, M.; Park, J. Evaluation of building energy and daylight performance according to applying electrochromic and pdcl (polymer dispersed liquid crystal) to office building in South Korea. Int. J. Sustain. Build. Technol. Urban Dev. 2019, 227–240. [Google Scholar] [CrossRef]

- Shaik, S.; Nundy, S.; Maduru, V.R.; Ghosh, A.; Afzal, A. Polymer dispersed liquid crystal retrofitted smart switchable glazing: Energy saving, diurnal illumination, and CO2 mitigation prospective. J. Clean. Prod. 2022, 350, 131444. [Google Scholar] [CrossRef]

- Scorpio, M.; Ciampi, G.; Rosato, A.; Maffei, L.; Masullo, M.; Almeida, M.; Sibilio, S. Electric-driven windows for historical buildings retrofit: Energy and visual sensitivity analysis for different control logics. J. Build. Eng. 2020, 31, 101398. [Google Scholar] [CrossRef]

- Hemaida, A.; Ghosh, A.; Sundaram, S.; Mallick, T.K. Evaluation of thermal performance for a smart switchable adaptive polymer dispersed liquid crystal (PDLC) glazing. Sol. Energy 2020, 195, 185–193. [Google Scholar] [CrossRef]

- Ghosh, A.; Norton, B. Durability of switching behaviour after outdoor exposure for a suspended particle device switchable glazing. Sol. Energy Mater. Sol. Cells 2017, 163, 178–184. [Google Scholar] [CrossRef]

- Hemaida, A.; Ghosh, A.; Sundaram, S.; Mallick, T.K. Simulation study for a switchable adaptive polymer dispersed liquid crystal smart window for two climate zones (Riyadh and London). Energy Build. 2021, 251, 111381. [Google Scholar] [CrossRef]

- Ghosh, A.; Mallick, T.K. Evaluation of optical properties and protection factors of a PDLC switchable glazing for low energy building integration. Sol. Energy Mater. Sol. Cells 2018, 176, 391–396. [Google Scholar] [CrossRef]

- Oh, M.; Lee, C.; Park, J.; Lee, K.; Tae, S. Evaluation of Energy and Daylight Performance of Old Office Buildings in South Korea with Curtain Walls Remodeled Using Polymer Dispersed Liquid Crystal (PDLC) Films. Energies 2019, 12, 3679. [Google Scholar] [CrossRef]

- Malek, M.R.A.; Aziz, N.A.A.; Alelyani, S.; Mohana, M.; Baharudin, F.N.A.; Ibrahim, Z. Comfort and energy consumption optimization in smart homes using bat algorithm with inertia weight. J. Build. Eng. 2022, 47, 103848. [Google Scholar] [CrossRef]

- del Rio, D.D.F.; Sovacool, B.K.; Bergman, N.; Makuch, K.E. Critically reviewing smart home technology applications and business models in Europe. Energy Policy 2020, 144, 111631. [Google Scholar] [CrossRef]

- Chen, Q. Ventilation performance prediction for buildings: A method overview and recent applications. Build. Environ. 2009, 44, 848–858. [Google Scholar] [CrossRef]

- Lirola, J.M.; Castañeda, E.; Lauret, B.; Khayet, M. A review on experimental research using scale models for buildings: Application and methodologies. Energy Build. 2017, 142, 72–110. [Google Scholar] [CrossRef]

- Alwetaishi, M. Impact of glazing to wall ratio in various climatic regions: A case study. J. King Saud Univ. Eng. Sci. 2019, 31, 6–18. [Google Scholar] [CrossRef]

- Tawfik, M.; Tonnellier, X.; Sansom, C. Light source selection for a solar simulator for thermal applications: A review. Renew. Sustain. Energy Rev. 2018, 90, 802–813. [Google Scholar] [CrossRef]

- Wang, W.; Laumert, B. Simulate a ‘sun’for solar research: A literature review of solar simulator technology. Ind. Appl. 2014, 50, 3055–3064. [Google Scholar]

- Colarossi, D.; Tagliolini, E.; Principi, P.; Fioretti, R. Design and Validation of an Adjustable Large-Scale Solar Simulator. Appl. Sci. 2021, 11, 1964. [Google Scholar] [CrossRef]

- Michael, P.R.; Johnston, D.E.; Moreno, W. A conversion guide: Solar irradiance and lux illuminance. J. Meas. Eng. 2020, 8, 153–166. [Google Scholar] [CrossRef]

- Zell, E.; Gasim, S.; Wilcox, S.; Katamoura, S.; Stoffel, T.; Shibli, H.; Engel-Cox, J.; Al Subie, M. Assessment of solar radiation resources in Saudi Arabia. Sol. Energy 2015, 119, 422–438. [Google Scholar] [CrossRef]

- Sobek, S.; Werle, S. Comparative review of artificial light sources for solar-thermal biomass conversion research applications. Ecol. Chem. Eng. S 2019, 26, 443–453. [Google Scholar] [CrossRef]