Date: 8 April 2016

During thermal toughening, these inclusions undergo a crystalline phase change to a smaller form and are fixed in place within the glass upon cooling. Over time the inclusions grow and can eventually impart enough stress in the glass to cause spontaneous failure.

When toughened glass panels fail, Nickel Sulphide (NiS) inclusions are the “go to” culprit. Independent research and development, consultancy and testing specialist, Glass Technology Services (GTS) is urging property owners and insurers not to assume that a NiS inclusion is the cause of an unexplained breakage.

GTS Glass Technologist, Dr Richard Cave, comments: “It should never be assumed that the seemingly spontaneous failure of a toughened glass panel is due to a NiS inclusion. Numerous other factors could be involved, such as non-NiS inclusions, vandalism, design flaws, poor toughening, edge damage and damage due to contact with fittings and fixtures. Any unexplained failures of toughened panels should undergo analysis to determine the true cause of failure.”

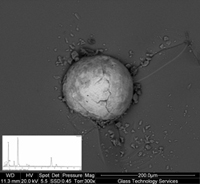

Even where a ‘butterfly’ failure pattern is observed – something commonly associated with a ‘spontaneous’ NiS failure – a NiS inclusion cannot be assumed. The three images below depict this same failure pattern, however, whilst one is due to a NiS inclusion the other two have resulted from a glassy inclusion within the glass and an impact.

When a fully toughened panel fails, the failure origin must be analysed in order to determine the cause of failure – therefore it is essential that the broken remains are retained for investigation. Once the origin is identified this is analysed using optical microscopy, scanning electron microscopy and energy dispersive x-ray spectroscopy, to identify the presence and nature of inclusions (NiS or otherwise) or physical damage.

Where inclusions aren’t to blame, physical damage and residual material can be analysed to determine likely contacting objects, whether it be from an outside source or from interactions with fixtures and fittings in the framing system.

These analytical capabilities and experience in glass enable the team to provide expert reports concerning a whole range of failures – ranging from external influences, such as vandalism and impacts, through to incorrect specification, interaction with components, material processing and fabrication or the presence of manufacturing defects.

“The industry knows that thermally toughened glass has numerous benefits over annealed and heat-strengthened glass, including better resistance to thermal changes, increased strength and safe breakage characteristics,” said Dr Cave. “Steps have been taken to eliminate NiS from the production of float glass, with changes in raw materials, manufacturing methods and processing techniques. The heat soaking process, introduced into manufacture by Pilkington in the late 60s, is also now recommended for all glazing installed in critical locations such as barriers or overhead glazing. Whilst it is not guaranteed to eliminate NiS inclusions altogether, the likelihood of spontaneous failure due to NiS is significantly reduced when heat soaking has been carried out.

“But NiS inclusion should never be assumed. Of the failed toughened panels examined by GTS in 2013, two thirds had failed due to the presence of NiS inclusions, with the remaining third a combination of impact damage, poor toughening, detrimental interaction with fixtures and non-NiS inclusions.

“To highlight this, a property management firm recently sent several failed toughened units to GTS for analysis after spontaneous failures had occurred throughout the building. Whilst analysis of the majority of the units identified the presence of NiS inclusions, other units featured impact damage at the failure origin.

“Ultimately, architects, engineers and specifiers should consider the benefits and drawbacks of all types of glazing before installation and ensure that they adhere to all relevant building regulations and codes of practice. Installers should adhere to the specifications and follow best practice to avoid unnecessary breakages.”

GTS is accredited to ISO 9001, ISO 14001 and ISO 17025 standards and is a Notified Body (number 2461) for the Initial Type Testing (ITT) of glass products under the European Union’s Construction Products Regulation (EU) No 305/2011 (CPR) in order to CE mark products for the European marketplace. The team provides analysis, consultancy, testing, research and development support to glass manufacturers, processors, tougheners, designers, architects, consulting engineers and specifiers across the UK and internationally.

600450

600450

Add new comment