Date: 8 November 2018

A new era is born from the total redesign of the smart glass storage and loading systems, taking advantage of the experience acquired during more than 30 years, to take this range of machines to a new dimension of performance, reliability and adaptability ready for the Industry 4.0.

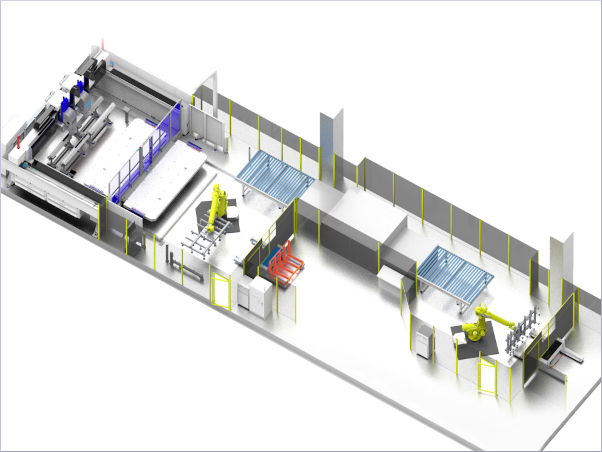

As a representative sample of the dark side of TUROMAS, the company exhibited at Glasstec a fully automated SR-07 storage and loading line for glass up to 7 meters, capable of working simultaneously with standard or Jumbo sized sheets of variable heights, with all sort of low emissivity coatings and thicknesses from 1.8 mm to 25 mm. The SR storage systems are particularly notable for their modular construction, which makes it possible for them to grow as the company grows, and for their almost unlimited capacity to adapt to the size and distribution of space, bridging the columns and even working between different warehouses.

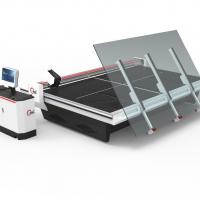

Along with the SR-07, TUROMAS completed the line with the world’s most advanced monolithic glass cutting machine, the RUBI 516C. Powered by linear drives technology, which was pioneered by TUROMAS almost 20 years ago, this table offers outstanding performance: maximum speed of 310 m/min and, most importantly, acceleration of 19 m/s2. It features the exclusive 4-Tool system, with 4 independent cutting tools specifically dimensioned to achieve a virtually perfect cut in any glass thickness without the need for any adjustments by the operator..

The machine exhibited at Glasstec fitted the Low-TPF advanced edge deletion system, also exclusive to our brand, designed to remove in one single operation both the Low-E coatings, the plastic protections of TPF glasses and hard EasyPro® layers. In addition, the table was equipped with the Lab-Print labeling system for the identification and traceability of each glass piece and remnant, which is fitted in the cutting bridge to increase the overall performance of the machine while maintaining compact overall dimensions.

The set of machines makes up what is nowadays the fastest and most efficient glass storage, loading and cutting line in the world.

Watch the video from glasstec 2018

600450

600450

Add new comment