Source: glasstec

Modern architectural interiors thrive on glass: open, light-flooded, transparent. However, confidential conversations, medical treatments or personal retreats require discretion. Switchable glass caters for both – in one single component controlled by electrical impulses rather than provided by blinds or curtains.

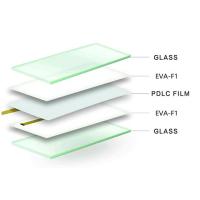

How PDLC works

PDLC is short for Polymer Dispersed Liquid Crystal – liquid crystals suspended in plastics. The heart of this technology is a thin film between two glass sheets with microscopically small liquid crystal droplets embedded in them.

The decisive factor: there is no mechanical element to this glass – this switching process is based solely on an electric field. At the touch of a button you send a signal to a control unit which then applies alternating current to transparent electrodes.

How opaque becomes transparent

Without current (“off” state): the liquid-crystal molecules are randomly oriented. Light is scattered into many directions – the glass surface appears milky and opaque.

With current: the electric field sorts the molecules. The refraction index of the droplets aligns with the surrounding polymer. Light passes through nearly unhindered – the surface becomes transparent.

This switching takes place within seconds. Film, electrodes and controller together invisibly, without any moving parts.

Applications in practice – from clinics to showrooms

Offices and conference rooms: transparency for teamwork, privacy for strategy discussions – the switch happens in seconds without any louvres that interfere with the video call.

Clinics and doctors’ surgeries: glazed fronts provide oversight and daylight. For treatments the same area can ensure privacy in a matter of seconds – with escape routes remaining visible and safety standards complied with.

Hotels and wellness areas: PDLC glass stages the changeover from open-plan areas to retreats. Bathrooms with glass walls appear accessible and airy by day but private and protected by night.

Showrooms and lab visits: targeted unveiling at times, temporary visual protection at others, without sealing off rooms permanently – ideal for presentations and publicly accessible areas subject to security requirements.

The combination of functional utility and minimalist design seamlessly blends with contemporary architectural concepts.

Other smart glass technologies by comparison

SPD (Suspended Particle Device): gradually dimmable and very fast in reaction. Optimal for glare protection and blackout as required in lounges or for car glass.

Electrochromic glass: generates a homogeneous tint but reacts more slowly. Primarily used on façades for smart daylight control, room comfort and energy efficiency.

Thermo- and photochromic glass: operate passively without power supply, react to heat or UV radiation. Cannot be controlled manually – suitable for simple standard applications.

Transparency as a design principle

Smart glass delivers what modern architecture calls for: transparency as a standard, privacy on demand. One single component connects openness with personal discretion – bright, accessible and yet ready for those moments where privacy is more important than transparency.

See how nature and glass can also enter into dialogue by visiting Haus Mischke-Götzinger in Berlin.