Date: 2 September 2020

Since its foundation in 2000, the company Trempver stands for quality and is known far beyond the borders of France. With 21 years of experience in the glass industry, Trempver has specialized in the production of tempered glass and special laminates and has a large product portfolio ranging from clear to lacquered glass, glass stairs to shower doors. The company has been a satisfied customer of SOFTSOLUTION since 2006 and has been using the digitizing solution VirtualDigitizing ever since.

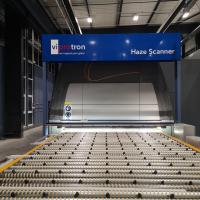

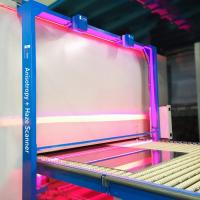

With the purchase of a CulletScanner in cooperation with the company Lisec Austria GmbH, Trempver now has another SOFTSOLUTION system in use. The CulletScanner, which was recently installed together with Lisec Austria GmbH, ensures quality control of their glass according to the EN12150 standard. "Thanks to the good and long-standing cooperation with Lisec Austria GmbH, Trempver has now decided on another quality assurance system from SOFTSOLUTION in order to be able to carry out automatic breakage pattern analyses of their glasses in the future" so International Sales Manager Jonas Pfannenstill.

The CulletScanner with a maximum scanning speed of 20 meters per minute analyzes the fracture pattern of the entire lite and finds automatically those ranges, which contain most, smallest, largest and longest fragments. These positions are highlighted and evaluated again in detail. The associated software provides all common known standards in this area. In the future, the French glass manufacturer will be well equipped to check its high-grade lites for quality defects in the shortest possible time - precisely, in constant quality and traceable.

600450

600450

Add new comment