Date: 9 October 2001

The basic principle of the system is to prevent any harmful environmental impacts that may arise from the company's operations. At the same time it supports the environmental philosophy of those Tamglass customer companies which require partners to manage their environmental affairs. Tamglass' environmental system has been certified by Lloyd's Register Quality Assurance.

When environmental questions are raised, the first things that often come to mind are the chemicals used in different industrial processes, aerial and waterway emissions, and problem waste. In the manufacturing of architectural and automotive glass, however, the environmental impacts relate more to energy and water consumption, and to noise. Hazardous chemicals or problem waste in the true meaning of the word do not arise from the processing of safety glass. Nevertheless, environmental matters are taken very seriously in Tamglass.

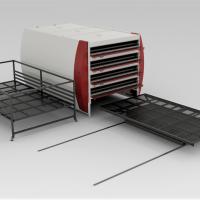

Tamglass Safety Glass Ltd's environmental philosophy extends all the way to the beginning of the production chain, namely to the choice of production machinery. Tamglass Safety Glass uses machines designed and manufactured by its affiliate company Tamglass Ltd in its production of tempered and laminated safety glass. The design of these machines has taken into account both energy consumption and the amount of water used in the process. Careful utilization of heating and cooling energy, closed water systems for the machines, and good sound insulation are all part of the implementation of Tamglass environmental philosophy.

In its production of tempered and laminated safety glass, Tamglass Safety Glass Ltd uses float glass, which is flat glass made from sand, soda ash, dolomite, lime and recycled glass. The float glass comes to the a factory with its edges protected by honeycombed board, which is returned to the float glass supplier for re-use. Waste glass created in the further processing of float glass is also recycled. Laminated and tempered safety glass, moreover, are always delivered to customers whenever possible such that the packaging materials can be recycled.

A matter for everyone

"In order to succeed, an environmental system requires that everyone working within the company is committed to applying the company's environmental policy. All of our company's employees, from senior management down are responsible for implementing the system," says Pertti Iivanainen, Managing Director of Tamglass Safety Glass Ltd. He views environmental matters as being wider in scope than the company's own activities. "Some of our customers, and their customers too, require us to operate according to an environmental system, and the number of such customers will surely increase in the years to come. Consumers in Western companies have also learned to ask whether the products they purchase are made in accordance with the principle of sustainable development," says Iivanainen.

In our living environment we are continually encountering things that are linked to environmental questions, even though we are not always aware of it. When a housing company glazes its balconies with the aim of improving living comfort and cutting heating costs, it is simultaneously acting in a way that saves energy and consequently also the environment.

"The automotive industry responds particularly critically to environmental matters; one of its important competitive factors is the resolution of environmental questions. The automotive industry has also been one of the first industrial sectors to start demanding that all of its subcontractors and partners, including manufacturers of automotive glass, operate in their own production in accordance with an environmental system," adds Iivanainen.

Economic

Taking environmental aspects into account in company operations need not raise production costs. This is true, of course, in some industrial sectors, but as far as safety glass manufacturing is concerned this has not proved to be the case. In fact it has been possible to control rising costs by means of a well implemented environmental management system that, among other things, saves on waste management fees by utilizing energy waste and by sorting and recycling mixed waste.

"How a company responds to environmental questions in its own activities tells a lot about that company's values. In terms of the company and, above all, the community and the individual it is absolutely vital to respond seriously to environmental questions. Any other attitude will no longer be tolerated in future," concludes Iivanainen.

Add new comment