Date: 4 June 2025

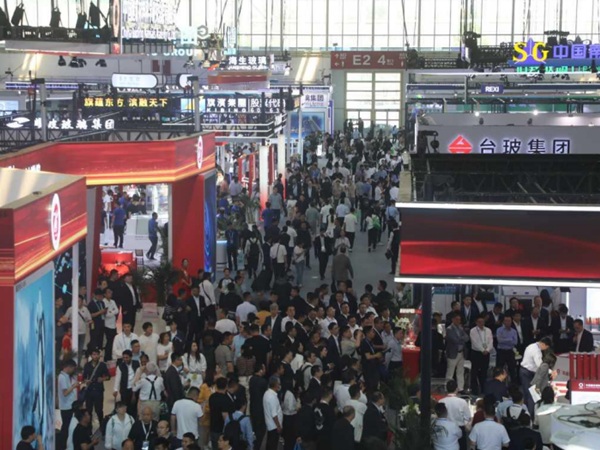

China Glass 2025 exhibition proved once again to be a resounding success, showcasing not only a vibrant atmosphere but also providing great opportunities to meet existing customers, form partnerships, and make new business connections across China and the APAC region.

China is taking determined steps to increase building quality and long-term energy efficiency. There are also increased warranty requirements for window and door producers in China. Glaston’s TPS® insulating glass technology is well-positioned as the leading solution to meet these growing and evolving standards.

Glaston’s TPS® technology is seen as a major enabler for increasing long-term building quality thanks to its longer unit lifetime and energy efficiency performance, even in challenging environmental conditions. To support the growth of insulating glass, Glaston’s tempering solutions are well-suited to reach the required quality and safety standards.

Another takeaway was the increasing demand for automation solutions across glass processing, which is also supported in Glaston’s technologies. For example, the innovative TPS® technology has advanced built-in automation levels that increase efficiency in the insulating glass manufacturing process while maintaining production quality. Another way to increase efficiency comes with applying the Thermo Plastic Spacer material directly onto the glass plate. TPS® eliminates the need to stock different spacer profiles and connectors. Changes to spacer width can be made during the process without losing time.

In addition, it can be noted that the EV market continues to grow in China. Glaston has its mobility pre-processing machinery production facilities in China, supported by the local glass supply chain, and is well-aligned to adapt and capitalize on this growth.

The Glaston team is at the forefront of innovative solutions in glass processing. Through strong collaboration with customers and partners, and with operations in Tianjin, we can demonstrate our solutions in action and manufacture our products to meet market needs.

China Glass confirmed again the importance of being able to trust the original innovator in the glass processing industry. Glaston will continue to work for setting the standard with advanced technology, exceptional reliability, and comprehensive lifecycle support.

600450

600450

Add new comment