Date: 2 November 2010

Today, after 116 years, the Sangalli Group is a well-established business operating in the Italian glass industry, and it is going to open a new production site in San Giorgio di Nogaro, near Udine, being its second flat glass line on the Italian territory.

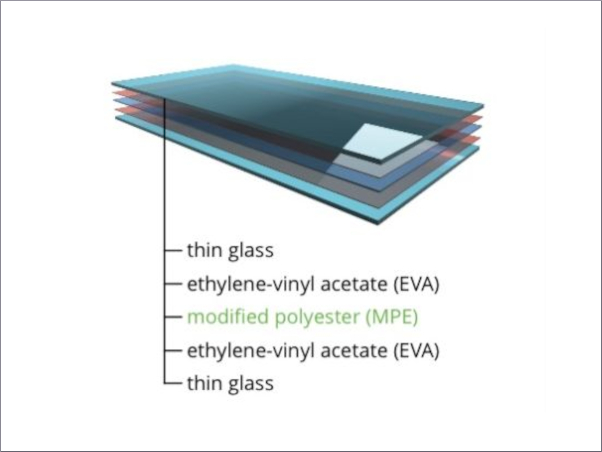

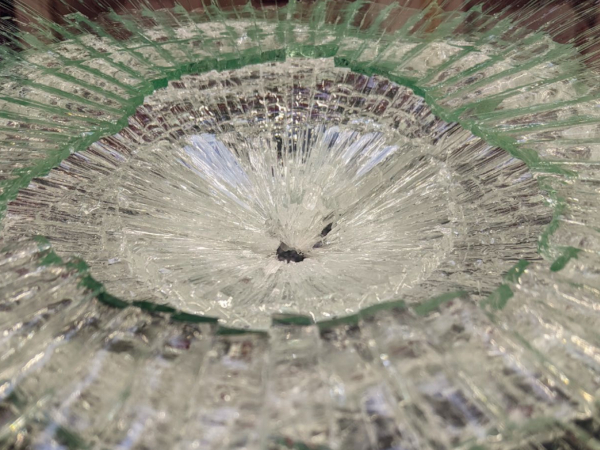

The quantum leap came in the ‘80s. These are the years when the development of technologies and production processes started to enable the improvement of the glass mechanical performance, finally overcoming that limit which for centuries had scared glass makers and prevented the extensive use of glass in architecture: the fragility.

At the same time, a new and widespread environmental conscience started to emerge resulting, in the more industrialized countries, in a number of norms aiming to protect the environment. The glass industry thus began to require products combining safety and particular performance levels in terms of energy efficiency.

It is in such a context that, at the beginning of the new millennium, the Sangalli Group decided to invest approximately 160 million euros in the construction of a glass center in Manfredonia. Sangalli Vetro Manfredonia S.p.A., producing the “Element” flat glass and the “Defender” laminated safety glass, was then soon followed by Sangalli Vetro Satinato, manufacturing the “Velvet” satined glass, and by Sangalli Vetro Magnetronico which, with its “Climax” and “ClimaxOne” ranges of magnetronic glass, positioned itself at the leading edge of the energy-saving low-E glass sector.

The Manfredonia production site, started up in 2002, being indeed the most advanced and efficient plant at work in Italy, enabled the group to produce and market 180,000 tons of flat glass per year, thus obtaining and maintaining a market share, in Italy, of approximately 15%.

Today, the market development and the rapid success of Sangalli Vetro Manfredonia are driving the group towards an expansion in terms of both geographic boundaries and products, increasingly oriented to the ever more exacting needs of the environmentally sustainable architecture.

The new site in San Giorgio di Nogaro, Sangalli Vetro Porto Nogaro”, will be focused on energy saving, and its most attractive products will include laminated glass, coated glass and the new “ElementExtralight” glass for the photovoltaic sector.

ocated 470km from Munich and 300km from Zagabria, its position will enable the company to serve, in a more efficient manner, the North of Italy, Austria, Romania, Germany, the Czech Republic, Slovakia, Swiss, France and the markets of Slovenia, Croatia, Serbia, Montenegro, and Albania, which currently consume about 6 kg of glass per capita every year, and are going to reach the European levels of 10-15kg, opening important target markets for the finished products.

The Sangalli Vetro Porto Nogaro plant will feature a very low environmental impact and will make it possible to eliminate the energy wastes due to the single production plant, and to acquire an increasing stability and visibility on the market, offering a wider range of products on a larger geographic area, as well as to provide an ever-improving service to its clients, in line with the traditional Sangalli family’s policy, being close to the customers and anticipating their needs.

Add new comment