Others also read

LineScanner - high precision dimension control of glass for drill holes, cutouts, notches and much more!

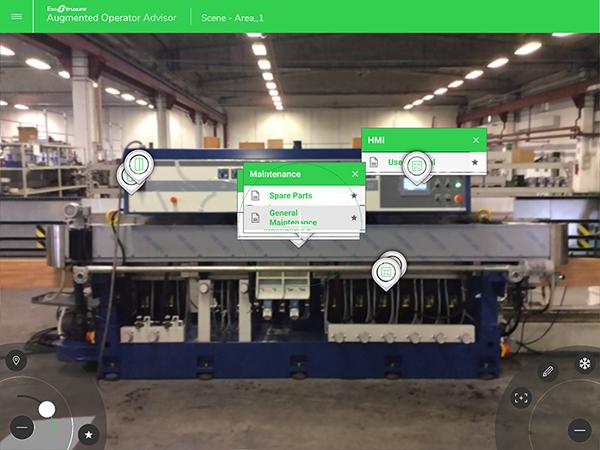

Industry 4.0, digitalization of processes, remote assistance: the levers of Bovone Group to enhance the business of its customers.

Federico Ratti, Innovations Director, sits on the committee, representing the global leader group in machines and industrial components.

The process of affirmation of 4.0 technologies on the current industrial scenario saw a significant acceleration in 2020.

Without a digitizing solution, customer supplied templates can often be a difficult task, as the Swiss company FRANZ GYSI AG can confirm.

Glaston is launching its new brand to communicate the full strength of the new Glaston.

Work is changing for many different reasons and not just because of the pandemic. How can mobile applications help your workers do more in less time? How can they help you increase your yield or revenue?

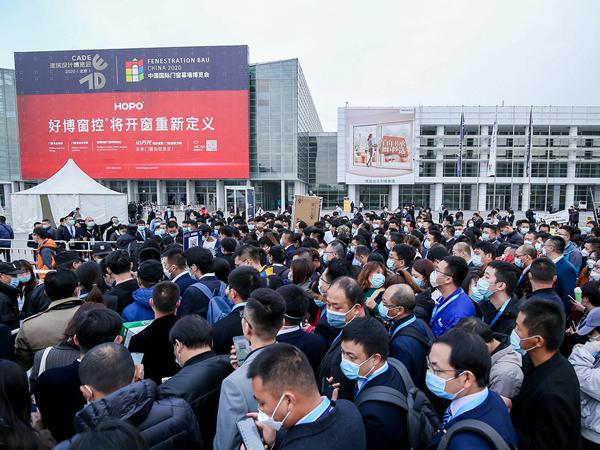

BAU China, the leading trade fair in the Asia-Pacific region for “Building Systems Solutions, High-End Technologies and Materials” was held from October 29 to November 1, 2020.

CulletScanner with tilt-function - new Video available! Automatic fragmentation image analysis with optional polarization function.

Live demos, talks with our experts and in-depth analysis of the main trends of the glass market.

Smaller fabricators are consistently overlooked when companies design, market, and sell ERP solutions. A+W Software is changing that for glass fabricators with the launch of our newest product called A+W iCut.

SCM and CMS, the two benchmark brands in the Scm Group's machinery sector, key players in the 57th edition of Smau, the annual Innovation trade fair held at the Fieramilanocity on 20 and 21 October.

SOFTSOLUTION - GLASS IQ is one of 750 exhibitors and presents automated quality assurance systems for the glass industry.

How can product quality and production processes in various glass applications be optimized by using Optris IR cameras and pyrometers?

Forel has released a special version of its “High Tech” IG line, equipped with a flexible spacer applicator and a “Hot Melt” sealing robot.

Experience the first ever virtual LiSEC Campus!

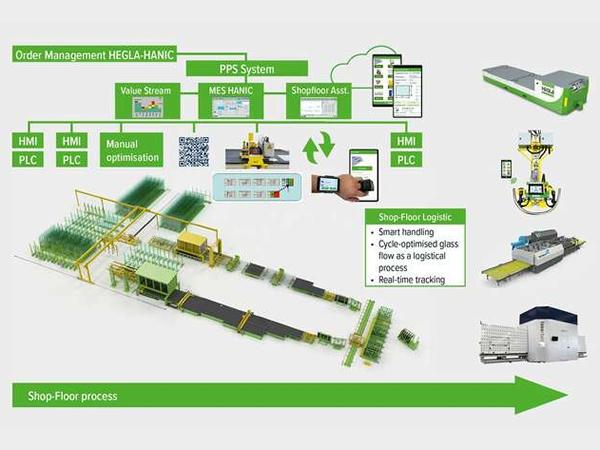

The glass production of the future will be fully networked and digitalized. Alongside digital support for employees, it will provide quick insight into machine capacity and even the current position of a specific pane.

High-quality glazing requires high-quality systems for the quality control of glass.

What needs to be considered when using infrared thermometers, IR cameras and our new glass inspection system in different glass applications?

After extensive tests and research Tryba has decided to use the reliable Quality Scanners from Viprotron.

Thanks to the latest developments, the LineScanner Management Console and artificial intelligence are now used to optimize processes.

The Cms Profile is the ultimate vertical CNC work-center. It can mill, drill, grind, polish, engrave, and seam.

Unlock the next step of automated production | October 7th at 4 PM italian local hour