Others also read

Sparklike, a global leader in non-destructive gas measurement solutions for insulating glass units (IGUs), announced the appointment of Sasu Koivumäki to its Board of Directors.

A perfect-looking IGU can still fail. Explore why visual inspection alone is not enough to ensure real IGU performance.

This year marks the 10th anniversary of Sparklike Laser Portable™, a major milestone in the development of non-destructive gas measurement for insulating glass units.

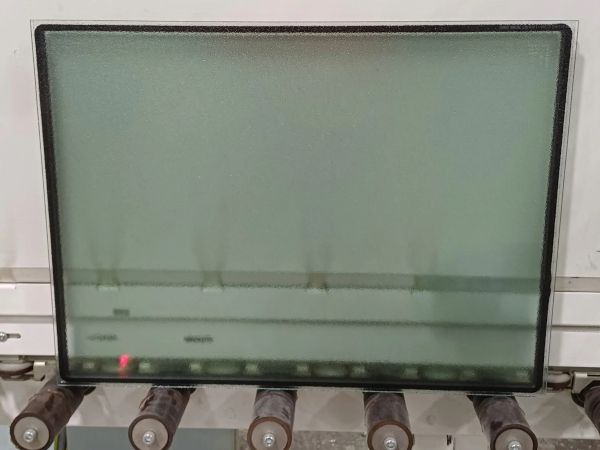

Chongzheng Shengda Glass opts for the first 8 × 3.3 metre TPA line from LiSEC.

When production gets more complex, strong partnerships make it sustainable.

As customer expectations for energy efficiency and glazing performance continue to rise, SafeGuard Glazing Supplies has reinforced its commitment to quality with the Sparklike Laser Portable™ 2.2.

As 2025 draws to a close, it’s a good time to reflect on business. We know for most glass processors, this has not been the easiest year.

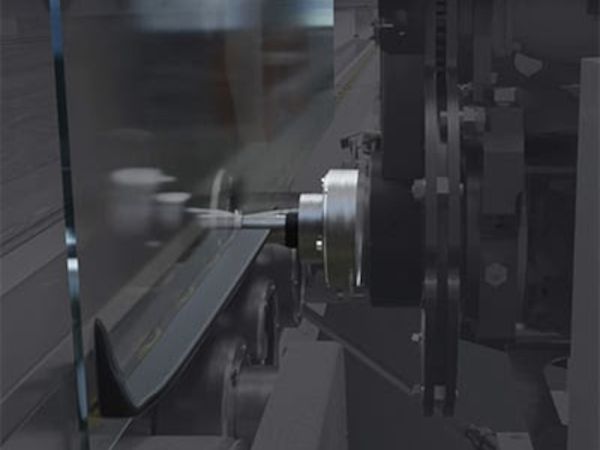

Discover how the new Glaston TPS® PRO technology sets a new benchmark in insulating glass manufacturing.

A forward-looking collaboration between NBS and Forel shows how automation and large-format glass production are redefining the future of industrial glass manufacturing in Japan.

Its recent investment in the innovative LiSEC SRP-A system underscores their shared commitment to digitalisation and greater efficiency.

NorthGlass has successfully delivered a fully automated smart manufacturing line for a key client in Vietnam, enabling high-precision, high-volume production that meets the demanding standards of global home furnishing brands, including IKEA.

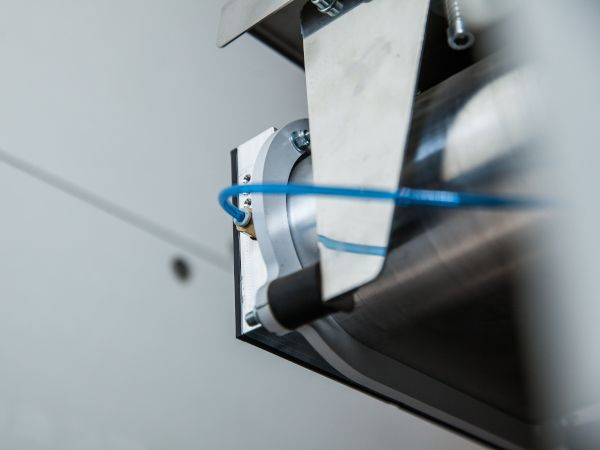

Discover how automated TPA application ensures accuracy, speed and reliable processing – even in large-format production.

The 2025 edition of GlassBuild America has concluded in Orlando, marking a record-breaking year for North America’s leading glass industry exhibition, which welcomed the highest number of exhibitors and visitors to date.

Sparklike Laser Integrated™ is a fully automated, non-destructive gas measurement system designed to be integrated directly into insulating glass (IG) production lines.

Sparklike continues to strengthen its global presence, connecting with industry professionals and showcasing its innovative gas measurement solutions for insulating glass (IGU) quality assurance.

From the GlassBuild 2025 show floor in Orlando, Forel & Quanex are highlighting the innovative collaboration that is bringing automation and spacer performance to the next level.

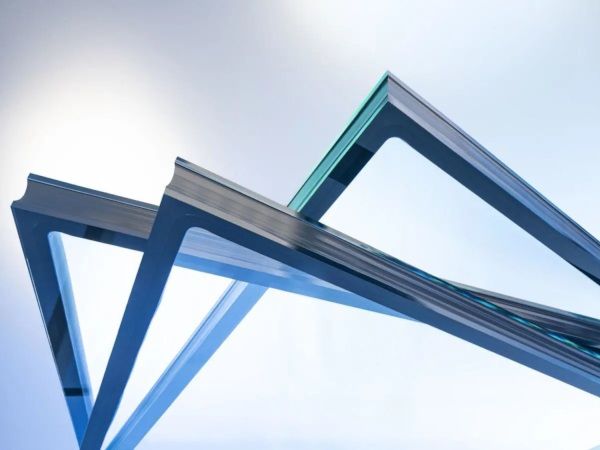

Forel introduces a new manufacturing solution for Triple Thin IGUs with Flexible Spacer, combining advanced automation, precision, and efficiency for next-generation insulating glass production.

With its new plant in Port Talbot, Press Glass UK is consolidating three locations and boosting efficiency and growth thanks to LiSEC automation.

At GlassBuild America 2025, Glaston showcases its latest innovations in glass processing, emphasizing smart automation, energy efficiency, and production flexibility.

First IGU line with a small footprint and high speed in the UK.

A long-standing partnership driven by innovation, technology, and a shared vision for excellence in architectural glass.

At Vitrum 2025, Forel showcased new technologies and solutions that push the boundaries of innovation and efficiency in glass processing.

The quality and durability of insulating glass units (IGUs) rely on precise manufacturing processes, especially when it comes to gas fill levels and leakage rates.

Now online: the new video dedicated to the manufacturing of triple glazed units with thin inner glass using the Forel High Tech line with TA thermoplastic spacer applicator.

Austrian window manufacturer Felbermayer has invested in turnkey LiSEC technology to achieve fully automated, high-quality insulating glass production.