Date: 19 January 2026

When projects become more complex and processing requirements more diversified, production processes need to evolve. It is from this need that the collaboration between Forel and Tritemplex began. Based in Perù, Tritemplex has over thirty years of experience in glass processing for residential, commercial and institutional projects.

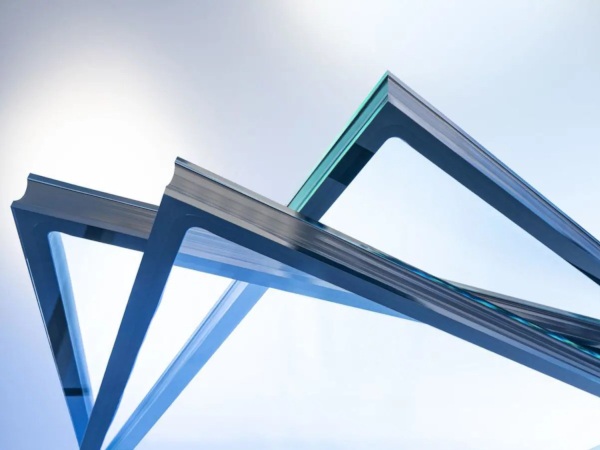

Over time, Tritemplex has developed a strong focus on bespoke solutions, working on projects that differ significantly from one another and involve specific requirements. This evolution has led to increasing production complexity, making it necessary to review the organisation of certain processes in order to continue ensuring quality and reliability in the final result, particularly in insulating glass production.

The start of an operational dialogue

This is where the dialogue with Forel began. Not with the introduction of a single technology, but with the intention of working on the process as a whole. From the very early stages, the collaboration was set up as a partnership, based on continuous discussion around real production needs and shared objectives.

The focus was on shaping a production flow capable of handling different types of processing without compromising quality. A path built on shared analysis and targeted decisions, leading to the definition of a production setup aligned with the company’s actual operational requirements, avoiding standardised solutions.

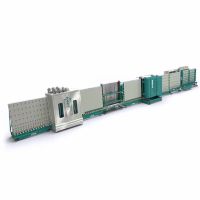

The INSULEX insulating glass line as an expression of the collaboration

Within this framework, the INSULEX insulating glass line was introduced, configured according to Tritemplex’s production needs.

The chosen configuration integrates a flexible silicone-based spacer system, a well-established solution within Forel’s insulating glass technologies, helping to reduce condensation risk and limit thermal bridging. The system is completed by silicone sealants designed to ensure long-term durability and resistance, even under extreme environmental conditions.

Over the long term

The collaboration between Forel and Tritemplex has been built over time, focusing on the process even before the technology itself. A path shaped by dialogue, shared decisions and attention to detail, resulting in a production setup designed to evolve while maintaining quality and reliability.

A story that reflects Forel’s approach: working alongside customers as a technological partner, with a constant focus on process quality and solutions designed to last.

600450

600450

Add new comment