Date: 16 October 2025

“At Premier DGU, we wanted to produce triple-glazed units with different cavity widths and depths on a fully automated basis. We see automation as key to our group’s future success by bringing us higher efficiency and quality. That is what this new Glaston IGU line allows us to do,” says Mark Harrison, CEO of United Glass Group.

United Glass Group is a group of four businesses operating in the UK architectural glass market. Premier DGU, based in Exeter, is the group’s most recent acquisition and the only company in the group that volume produces insulating glass units (IGUs). The other companies – Brownhills Glass and Tufwell Glass are flat glass processors, and London Architectural Glass is a specialist in structural units and fire-rated products.

“When we acquired the 40-person business in Exeter, we wanted to grow the business, building on the excellent work of Premier DGU’s founder, Barry Clarke. To do that, we needed additional capacity to improve output on a more automated basis,” says Harrison.

They saw local growth opportunities in an increasing demand for high-performance glazing by offering enhanced thermal properties and energy efficiency. They recognized they might also sell IGUs to customers throughout the group and knew that being able to produce triple-glazed units with varying cavity depths would meet a broader range of customer requirements.

Moving forward quickly

Once the acquisition of Premier DGU was finalized in September 2024, Harrison jumped on a plane with Barry and Ross Worrall, Glaston’s UK representative, to see one of Glaston’s IGU lines in operation near the Czech border. Although United Glass Group has multiple Glaston furnaces running across the group, this is the first time they had purchased an IGU line.

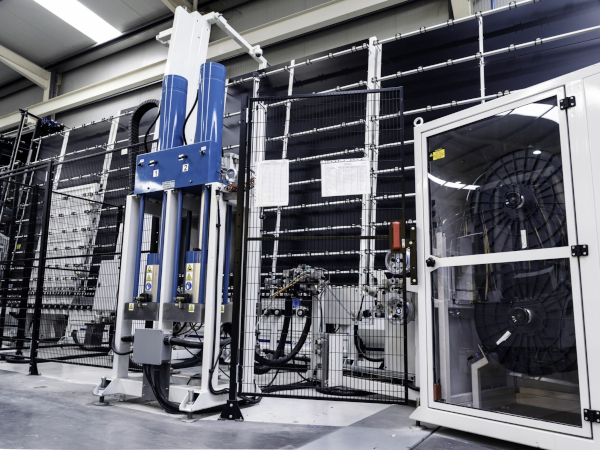

United Glass Group placed an order later that month for a Glaston VARIO FLEX triple-glaze line. The line automates the production of gas-filled and sealed insulating glass units and incorporates flexible warm edge and rigid spacers.

Keeping strict timelines

The Glaston VARIO FLEX line, the first of its type and size in the UK, arrived in Exeter over Easter weekend in April and was installed over the next four weeks. An old line needed to be removed to make space for the new Glaston one.

“We faced a huge risk of disturbing the business, going from two lines to one while the new one was being installed,” he says. “That risk was successfully managed by Glaston strictly adhering to their timelines, and installation was smooth. In addition, Glaston was able to condense everything to fit into a relatively small footprint, without compromising cycle times.”

Line operating well with quality results

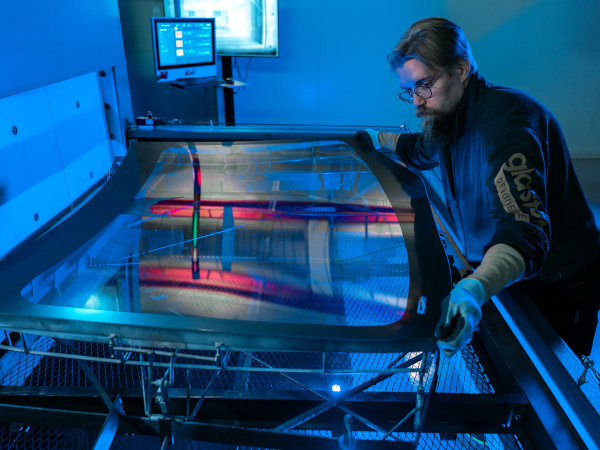

Training was comprehensive, and Premier DGU was happy with the engineering team that handled the project on-site. The line met all its performance criteria very quickly in the testing phase.

“I feel Glaston went out of their way to make sure we had our favorite engineers available,” he adds.

The line has been up and running since late May. “We’re still making some refinements, as happens with these kinds of projects,” Harrison says. “But the line has been operating reliably, the speed at which it is operating is what we wanted, and the quality coming off the line is very good.”

He goes on to say the operators are finding it fairly straightforward to use. There was an issue at first with the software recognizing the different sizes of glass, but once that was overcome, everything has run smoothly.

“Once the holiday season is over at the end of August, we plan to start talking about our extra capacity. We are also informing existing customers about our new triple-glaze technical capability, a key driver for the initial investment,” Harrison says. “We also plan to introduce Premier DGU products to customers elsewhere in the group where there is a willingness to have those conversations.”

Automating brings efficiency and quality

Today, the fully automated line manufactures complete IG units in just over 60 seconds, producing both double- and triple-glazed sealed units with exceptional precision.

A feature that has most impressed Harrison includes the ability to automatically produce triple-glazed units with different cavity depths for Premier DGU’s Edgetech brand of spacer systems.

Going forward, United Glass Group as a whole will continue to automate. “We see automation not only in Premier but also in the other businesses as being key to our future success,” Harrison says.

This investment represents a major leap forward, positioning both Premier DGU and the United Glass Group at the forefront of high-performance glazing solutions in the United Kingdom.

Glaston in brief

Glaston is the glass processing industry’s innovative technology leader supplying equipment, services and solutions to the architectural, mobility, solar and display industries. The company also supports the development of new technologies integrating intelligence to glass.

Glaston is committed to providing its clients with both the best know-how and the latest technologies in glass processing, with the purpose of building a better tomorrow through safer, smarter, and more energy efficient glass solutions. Glaston operates globally with manufacturing, services and sales offices in nine countries and its shares (GLA1V) are listed on NASDAQ Helsinki Ltd. For more information visit glaston.net.

600450

600450

Great!