Others also read

A reminder that June 19, 2021 is the last day to reserve your space at VITRUM 2021.

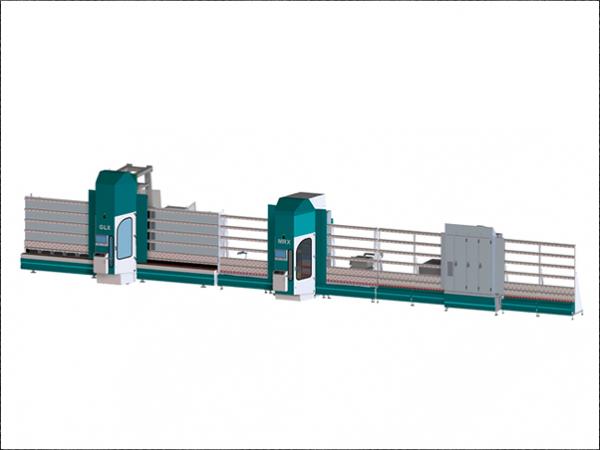

The combiFIN is the fastest and most uncomplicated type of vertical processing of medium-sized glass formats with optimum cycle times and cost-effectiveness.

VITRUM programming will be complemented by that for GLASS WEEK, broadcast from the event Hub and on the dedicated digital platform.

4 video episodes streamed on YouTube to discover the Italian Glass Working excellence

In their path for a always higher technology, Q4Glass choose Forel as a supplier for the vertical processing machinery.

The order, valued at approximately EUR 9 million, includes in addition to one tempering line, several insulating glass lines, a grinding line as well as other equipment.

The exhibitor registration deadline has been extended for another 60 days: you now have until May 19 to fill out and submit the application form.

Meet Vitrum 2021: where the glass industry comes alive - The next edition of Vitrum revealed: “Ready for the challenges of the present and focused on the future of the show”

3 or 4-axis (optional) Numerically Controlled machining center to machine both thin and thick flat glass as well as laminated glass and bullet-proof glass.

The date to reserve space at VITRUM 2021 by taking advantage of the Early Bird rate has been extended to February 15, 2021.

The glass is available in sedak maximum dimensions up to 3.6 x 20m.

combiFIN is a compact but simultaneously highly efficient vertical processing line for flat glass with a thickness of typically 4 to 12mm.

Italian companies share their thoughts and expectations about the show and relaunch of the glass sector.

VITRUM President Dino Zandonella Necca and Director Fabrizio Cattaneo illustrate how the qualities of glass represent new cornerstones of the fair: initiatives, activities and new thematic layout will guide the end user through a new and enhancing…

The first positive signals confirm that Vitrum continues to be the main international event

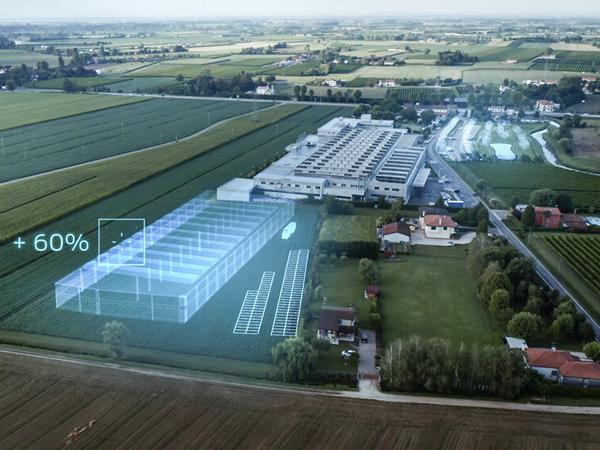

The enlargement of the Forel production plant (Treviso-Italy) is set to begin in 2021.

Reservations are now open for your space at VITRUM 2021, to be held in pavilions 22 and 24 at Fiera Milano Rho from Tuesday, October 5th to Friday, October 8th.

VITRUM President Dino Zandonella Necca commented on the position made public by GIMAV.

The Cms Profile is the ultimate vertical CNC work-center. It can mill, drill, grind, polish, engrave, and seam.

CMS Glass Technology is the industry leader in machining bent glass using the CMS Maxima CNC machining center.

Grinding with Belleville washers makes the edges shiny and completely defect free.

What C.Bergmann appreciates most about the 32 years of cooperation with LiSEC is the consistently high quality of the long-lasting LiSEC machines and the tangible proximity to the customer.

Officina Meccanica Schiatti Angelo s.r.l. is more than just machinery, they are partners who take time to solve your specific problems to add value to your operation.

In our highly connected and modern society, we use in our daily life an increasing amount of applications covered with glass. We are surrounded by touch screens in different sizes: from mobile phones and tablets to big glass screens and interactive…