Date: 25 September 2020

The Nautical industry is continually evolving with yachts requiring more and more complex shapes. Each piece of glass needs to be manufactured to fit perfectly into a frame. Therefore, extremely tight tolerances are needed to produce these parts.

During the bending process, the size of the glass varies by several millimetres from the required specifications. The logical solution is to machine this glass after it has been bent.

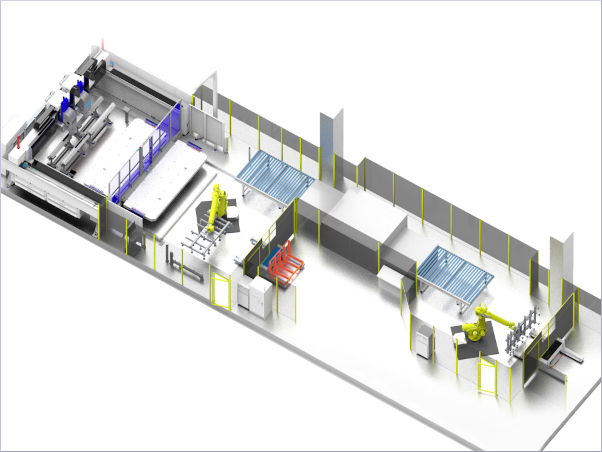

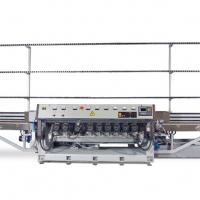

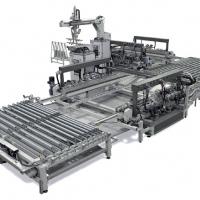

CMS Glass Technology is the industry leader in machining bent glass using the CMS Maxima CNC machining center.

TOP BUYER BENEFITS

- 23% time saving with assisted positioning of the suction cups

- no vibrations due to the rigidity of the rotating axes

- +/- 0.05mm tolerance on the profile

Thanks to the assisted positioning system, the Maxima shows the operator where to position the suction cups on the table and also gives the proper positioning angle to accommodate the bent glass part.

Once the glass has been positioned, a dynamic measuring system is used to probe the surface and adjust the geometry of the program to match the actual bent part. This allows for consistent grinding and polishing of the edge around the entire perimeter.

TECHNICAL SPECIFICATIONS

- Z axis up to 1,400 mm at full speed

- 40 HP electro-spindle for the most demanding machining

- Full visibility of the work area

600450

600450

Add new comment