Date: 9 January 2024

Since establishing their presence in the US through an acquisition, Poland-based Press Glass has continued its brisk growth based on the same values that make it the #1 glass fabricator in Europe and the UK. The company’s latest US investment is a Glaston ProL convection control upgrade at its Ridgeway, Virginia, plant. This upgrade helps reduce remakes and raise on-time delivery to 98%.

Press Glass was founded in 1991 in Poland with a single line for IG units. During the next 10 years, the company grew tremendously, exporting IG units and later moving into commercial architectural glass. Currently, Press Glass is headquartered in Konopiska near Czestochowa, Poland, with 13 European factories throughout Europe.

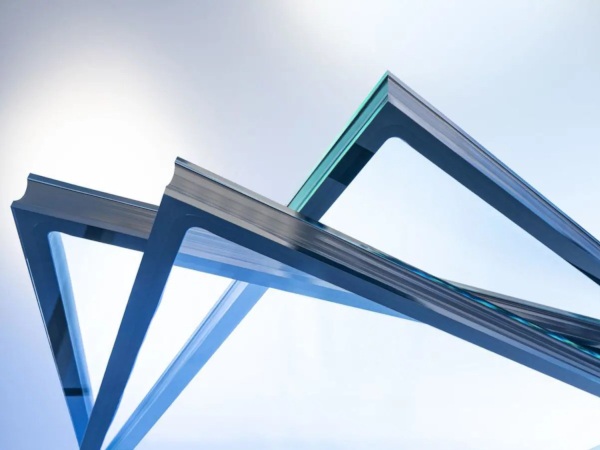

To move closer to customers in the US and Canada, Press Glass acquired Glass Dynamics, Inc., a glass fabricator in Stoneville, North Carolina, in 2017. Over the next three years, the company expanded its presence in the US with the establishment of a 270,000 sq. ft. state-of-the-art facility in Ridgeway, Virginia, only 7 miles north of its first location. Today, with over 500 employees in the US, Press Glass has evolved into a one-stop glass fabricator of architectural flat glass for construction projects on the East Coast and across North America.

LASTS LONGER, WORKS BETTER

Glaston and Press Glass share a longstanding partnership. Most of the tempering lines in Press Glass’s European facilities are from Glaston. The company’s US branch has Glaston FC Series and Jumbo Series tempering lines at the Ridgeway factory for larger projects and an additional smaller line in Stoneville for smaller IG units and heavier interior glass. Currently, a fourth line – another tempering furnace – is being assembled and will be delivered soon.

“Glaston is considered the ‘Cadillac’ of the market. The price point may be higher, but Glaston machinery lasts longer and produces higher quality,” says Gregg Vanier, Director of Manufacturing and Technology at Press Glass.

FIRST PROL CONVECTION UPGRADE

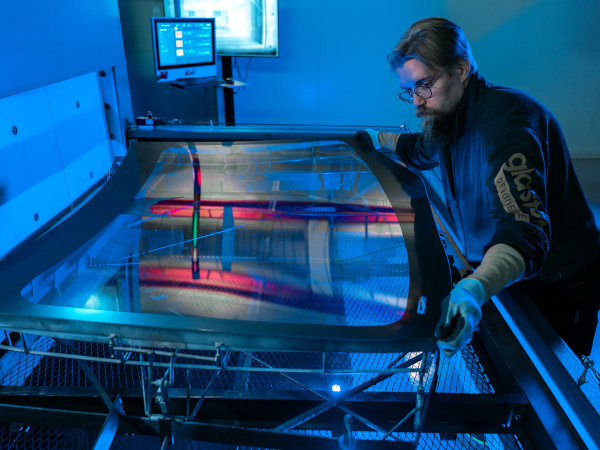

In another move forward, Press Glass was the first in the world to invest in Glaston’s convection upgrade for its lamination line in Ridgeway, completed in April 2023.

“It was clear we needed to upgrade when the market started asking for more complex end products. We needed better control to help process the multilayer laminates that are more common in the US market than the monolayers in Europe,” Gregg explains.

The ProL convection upgrade helps eliminate trapped air inside the layers that causes a lack of adhesion.

“Since commissioning, we have been able to gain traction in the market. We just had our most efficient production period in terms of square footage produced per day. The upgrade also led to higher quality, enabling us to reach 98% on-time delivery,” he says.

He also emphasizes that remakes have gone down since the upgrade, and this helps manage production costs.

Additionally, the new upgrade features have significantly simplified the lamination process itself, further contributing to the overall efficiency.

MINIMIZING LOST REVENUE

Installation was supposed to last eight days, but Glaston’s Hamed Tabatabaei and Andres Londono finalized the upgrade in just four days, two of which were over the weekend.

“This helped us minimize our chances of losing revenue – which we really appreciated,” Gregg underlines.

“The entire process was well planned and executed. The fact that the team completed the project well within our time constraints means a lot. Minimal production time loss along with great people equals success,” adds Chris Hayzlett, Maintenance Supervisor, Press Glass.

TRAINING MAINTENANCE LEADS TO BIG GAINS

In October 2023, Glaston also organized a tempering training session, giving the Press Glass maintenance team a thorough understanding of the maintenance and recipes for their tempering lines.

“The training has clearly helped us increase capacity and decrease quench time,” Gregg says. Another workshop is planned for February 2024 to continue training the team.

SUSTAINABILITY IN RECRUITMENT AND OPERATIONS Ongoing training is just one of the ways that Press Glass aims to recruit and retain employees in their rural area. One of the company’s strategies is creating a workplace that offers challenging and satisfying work with automation and computer systems.

“The glass processing industry is surprisingly clean. Much of the heavy work has been replaced by automation, allowing employees to do mental rather than physical tasks,” says Gregg.

“HAPPIEST PLANT I’VE EVER WORKED IN!”

Implementing quality processes and quality checks is also essential, and collaborating with companies such as Glaston is an integral part of Press Glass’s commitment to delivering unparalleled quality. “We want to make sure we provide the quality our customers and architects expect. Nothing can leave our plant that is not acceptable,” Gregg adds.

Press Glass sees its customers and suppliers as partners in all it does. And its employees are proud of being part of a big family.

“I have to say this is by far the happiest plant I have ever worked in,” Gregg concludes.

600450

600450

Add new comment