Date: 9 November 2022

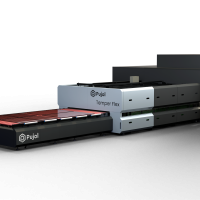

Recently, under the dual external adverse conditions of the epidemic and the war, NorthGlass top series of tempering furnaces have passed acceptance and been delivered to Russian customers, which marks another solid step forward for NorthGlass to develop the global high-end tempering market.

The most important feature of NorthGlass top series of tempering furnace is the intelligent temperature control system. The system real-time monitors the temperature of the glass through the setting of multiple high temperature probe on the furnace body, according to the probe feedback by intelligent algorithm to forecast glass temperature rise trend and automatically adjust the heating time, which changes the traditional setting heating time to control the glass heating degree and achieve accurate control of glass temperature.

Simply, the intelligent temperature control system is like the automatic exposure technology for a smart camera. Before automatic exposure, the photo is determined by the level adjusting the aperture and the speed of the shutter. The birth of the automatic exposure technology makes the ordinary people have the chance to record the wonderful moment only by simply pressing the shutter, and the birth of the intelligent temperature control system enables the operators to steadily produce the desired products by setting temperature, which is another revolution of NorthGlass tempering heating technology.

Another feature of the intelligent temperature control system is the extreme fine heating partition layout, it achieves more accurate area heating on the basis of gapless heating to further reduce the light distortion of the glass.

The maximum processing size of this NorthGlass top series tempering furnace is 3400x6000mm, and customer has produced two consecutive shifts a day for two months. The equipment has hundreds of production formula, and it can be used for the production of ordinary white glass, color glass, Low-E and other kinds of glass. At the same time, it has a full tempering, semi-tempering, fireproof and other production modes, and it has intelligence, energy saving, high quality, stability in one, making customers are full of praise.

600450

600450

Add new comment