Date: 21 March 2006

Transparency, light and maximum visibility are important design criteria for modern cars. The amount of glazing used in vehicles is steadily expanding, and the glass is increasingly also being expected to perform new functions. In production, the specified optical properties of the glass need to be perfectly met the product needs to be completely flawless. The SCREENSCAN-Final from ISRA VISION is the only system in the market which enables complete and fully automated inspection of windshield glass. With its three modules Straylight-Module, Absorption-Module and Distortion-Module (SCREENSCAN-Faultfinder), the system checks for all types of fault that can occur, thus guaranteeing a perfect view of the road.

Glass is a fascinating material. Even as far back as the Stone Age, man has used naturally occurring glass like obsidian to make tools for example as a hand-axe. Systematic production of glass vessels and jewelry probably started late in the third millennium B.C. in Mesopotamia. The first documented evidence of man-made glass production dates back to around 2000 B.C. in Egypt, where panes of glass were manufactured by melting glass sand on molten lead. However, it was not until 1827 that new technology which enabled glass to be mass-produced was developed.

Glass as an indispensable material

Today, glass in its many forms is an indispensable material in automotive engineering. Particularly in windshields, where glass provides the driver with a clear view of the road ahead, whilst at the same time offering protection against wind, weather and airborne particles. However, uniform and distortion-free transparency can only be achieved with precisely manageable and controllable manufacturing processes that deliver flawless surfaces and structures. In addition, the homogeneity, dimensional accuracy of the contours and the quality of the edges are among the key quality criteria of glass products.

The increasing functionality of automotive glass is also remarkable: as well as the original protection function. Car glass now also houses aerials, mirrors and rain sensors, contain anti-frost systems and are even coated with an infrared reflection layer. In the future, head-up display zones should help to deliver information more reliably to the driver.

It is very important that automotive glass has no defects not just for aesthetic reasons, but primarily also for safety reasons. The list of potential flaws is long: scratches, surface irregularities, hairs trapped in the laminating layer, particles of fluff or dust, optical distortion or tiniest spot flaws. Accordingly, rigorous quality standards are applied during the production of automotive glass. However, to check that a glass component is genuinely completely flawless you will need a powerful automatic inspection system.

Fully-automated instead of manual

With the SCREENSCAN-Final, ISRA VISION has now introduced a system which enables complete and fully-automated inline inspection for final inspection of windshields. At present, most inspections of this type are usually only performed in the form of a visual inspection. Although a human inspector is certainly capable of detecting nearly all of these types of defect, fatigue will have an impact on the quality of inspection. This means that, with time, the difficult search for what are essentially tiny flaws on the transparent or coated glass surfaces will gradually diminish the ability of the person carrying out the inspections to perform them to the required level of reliability. It also becomes difficult to qualify and quantify all flaws absolutely correctly after a certain amount of time. Manual methods also usually fail to deliver reproducible values for assessment of the flaws.

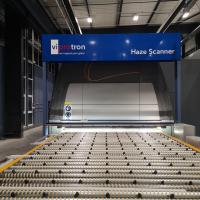

With the SCREENSCAN-Final system, ISRA VISION now offers a system which allows a fully-automated final inspection to be performed which checks for all types of flaws at conveyor speeds of up to 600 mm/s. The development of this system has drawn on the extensive expertise and experience of the manufacturer in the inspection of flat and curved glass. The system is capable of detecting even the tiniest flaws, such as scratches or hair or fluff trapped in the laminating layer, with the utmost precision. It then qualifies and quantifies the flaws on a reproducible basis.

Three independent modules combined to one

SCREENSCAN-Final is a modular system which is made up of three modules. Firstly, the Distortion-Module (SCREENSCAN-Faultfinder) is used to inspect the vertical and horizontal transmitted distortion of the glass. In the process, it uses the patented online-Moiré- technology to evaluate optical distortion which can be generated for example during the bending process. For over 5 years now, the SCREENSCAN-Faultfinder has been used successfully by all of the well-known manufacturers.

Secondly, the Absorption-Module checks the glass for light-absorbing faults, for example hairs trapped in the laminating layer, spot flaws and similar, and it also checks the edges for defects. The latter check includes for example measurements of the foil protrusion and an inspection of the condition of the edge surface. In addition, this module also detects faults in the screen printing process, for example holes in areas printed black, and it can also check the position of any screen-printed areas, ranging from logos and markings to the base for the rearview mirror. In the case of the Absorption Module, the camera focuses from the outside of the windshield directly onto the windshield, which is illuminated from the inside.

Finally, the Straylight-Module inspects the windshield for faults which cause light to be scattered, for example scratches, surface irregularities, chips and similar. With this module, the camera is directed at an angle of 0° onto the outside of the windshield, just like in the case of the Absorption Module. The illumination is provided by light which is reflected from various high power sodium lamps arranged at different angles. This also makes it possible to detect scratches from the outside on printed areas. This specially developed illumination system helps to distinguish scratches from dirt. The module normally detects scratches with a minimum length of 2 mm and edge defects like surface irregularities or chips greater than 1 mm. The module then uses reference scratches produced under defined conditions as samples for system validation to qualify the defects. This allows the system for example to detect smaller scratches without rejecting the windshield.

Each of the three modules can be used individually or in combination. An industrial PC is used as the intelligent part of each of the modules. A central control computer, which also serves as the man-machine interface, is provided for all three modules. The computers communicate via Ethernet. The inspection system can be integrated seamlessly into the process chain for automotive glass manufacturing.

Software

One of the key attractions of the system is the system software, which can be flexibly adapted to the requirements of each individual user. Different user interface views can be used for different users, for example users at operator, service and management level. The system software offers a user-friendly module for teaching the system new types of windshields or new types of defects. This so-called "QUICKTEACH" concept allows you to teach the system through a process of demonstrating the relevant new type of windshield or defect. In addition, it also offers extensive help functions and online statistics.

By logging into the company network, quality managers can also use the View-Station function to gain an overview of the inspection

As a standard service, the inspection system can also be serviced remotely by ISRA VISION. Experience has shown that nearly 90% of all problems can be solved quickly and cost-effectively with the aid of a controlled and password-protected dial-in system e.g. via modem or VPN.

SCREENSCAN-Final is a fully-automated system for inspecting curved glass. For automotive glass manufacturers, it represents a tool which can be used to achieve consistently high quality in production and a means for improving control over the glass manufacturing processes. The information made available by the system software is invaluable for quality assurance and production optimization purposes. With this inspection system, manufacturers will gain a noticeable edge over the competition.

Add new comment