Date: 30 May 2011

After purchasing a beveling machine from the company last summer, Unit Art management were so impressed by the production standards and after care services that they have made further investments with the leading glass machinery distributor.

Unit Art Glass is a family run business that was established over 10 years ago, initially providing stained glass for sealed units. The company has since diversified its product portfolio to include sealed units and latterly made the transition into processing glass.

.jpg) This development was given substantial research over a number of years with a view to further expanding the business. Consequently, this has resulted in the need to streamline manufacturing methods and purchase a new Fratelli Pezza Mistral M120V sandblasting machine to help further automate the company’s facilities.

This development was given substantial research over a number of years with a view to further expanding the business. Consequently, this has resulted in the need to streamline manufacturing methods and purchase a new Fratelli Pezza Mistral M120V sandblasting machine to help further automate the company’s facilities.

The Mistral offers an automatic or manual, numeric-control sandblasting cabin along with entry and exit glass supports, each being 1.400 mm. in length. Additionally there is an automatic 4.000 mm long conveyor belt which is lined with a special wear proof and cut proof material.

Stepped movement of the Mistral 120’s glass plate is programmable according to the type of sandblasting to be implemented, with the movement being able to be set with a continuous motion.

Having carefully researched products on the market, for Unit Art Glass the fully automated machinery has made vast improvements to on-site efficiency and output at the company since its installation, having made production faster and cleaner to work in for operators.

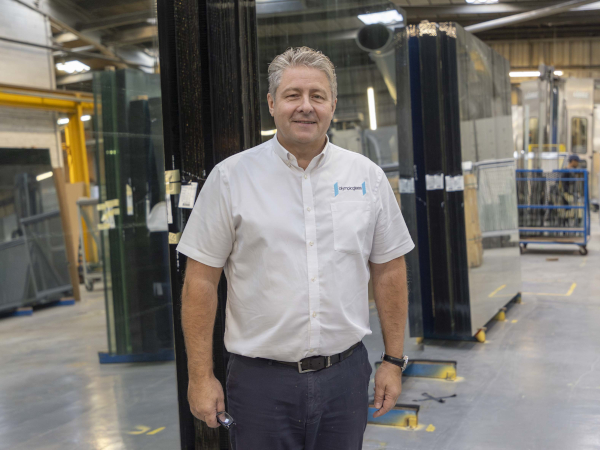

Unit Art contacted The Glass Machinery Company based on the company’s previous business dealings with Darren Bill, Sales Manager. The sandblaster was subsequently installed with minimum disruption to ongoing manufacturing procedures along with on-site training which was all completed in one day.

Neil Tomlinson, Managing Director at Unit Art Glass stated that the quality of products available from The Glass Machinery Company were of a better quality to others on the market and were very competitively priced.

Neil Tomlinson comments: “As our processing side is expanding considerably with this side of the business generating a larger proportion of income we needed to evaluate and consider our future needs. Soon the company will be diversifying into the door market so it was essential that we purchased the right equipment to meet the high standards for which we are recognized with both our existing and potential customers.

The Glass Machinery Company team has excelled in terms of products, performance guarantees and an extremely efficient after-sales care service. The credibility of the company is superb and they can advise us on all our technical requirements”.

Darren Bill, Sales Manager at The Glass Machinery Company comments, “We are delighted to see that the sandblaster from Fratelli Pezza is making a difference and helping to boost production standards for Unit Art Glass. We aim to provide only the highest standards in respect of both products and service support so it is rewarding to know that this is recognized.”

Add new comment