Date: 6 June 2017

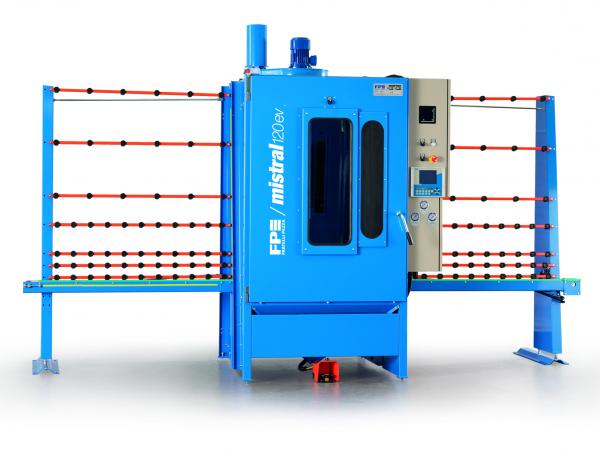

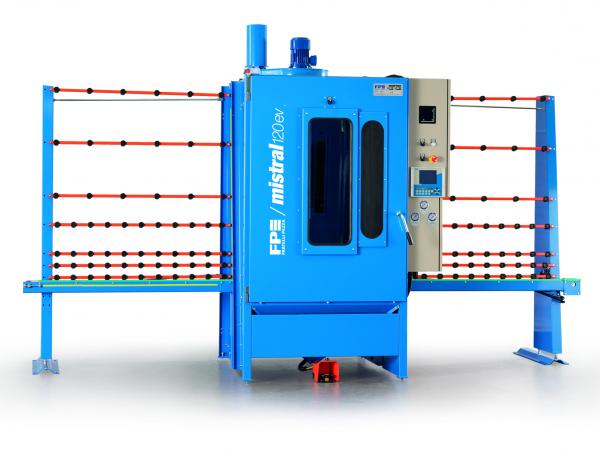

The machines of Fratelli Pezza product range, the automatic cabins of the ZEPHIR and of the MISTRAL EV series, are characterized by extremely low consumptions, more than half of the market average.

That’s why an equipment Fratelli Pezza is undoubtedly the best solution among the options available on the market.

Talking about the small and medium size equipment (Zephir 120 and 180 and Mistral 120EV and 180EV) the electrical consumption is only 2 kW, while for the biggest model Mistral 260EV is only slightly higher, 3 kW.

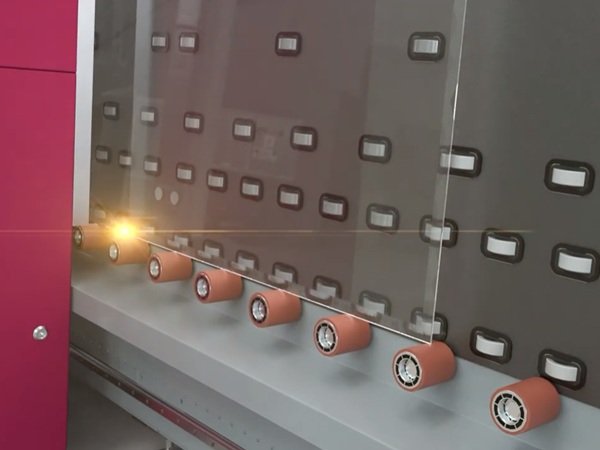

Moreover, the consumption of compressed-air is remarkably lower than any other sandblaster available on the market, only 500 lit/min. for each automatic gun.

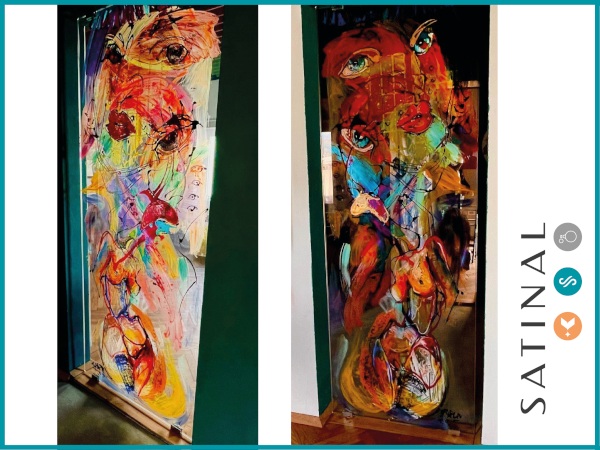

Such reduced electrical and compressed-air consumption allows to save a lot of money in the medium and long term, without forgetting about the highly efficient built-in filtration system, which allows important savings in the consumption of abrasive material.

The blasting media is automatically recovered in the working cycle while the dust is drawn into the filtration chamber.

Using extra quality aluminium oxide supplied by Fratelli Pezza, with 20 Kg of abrasive it’s possible to blast up to 100 sqm. of glass.

The effectiveness of the filtration system as well as the perfect tightness of the cabin allow to keep the particle emissions at an extremely low level, far below the regulatory limits.

600450

600450

Add new comment