Wangcheng Ave, 12

Xigong Qu

Luoyang Shi 471000 Henan Sheng

China

Landglass Technology Co., Ltd

Company address

COMPANY DESCRIPTION

Landglass Technology Co., Ltd is a professional, experienced hi-tech enterprise specializing in developing, designing and manufacturing glass tempering furnaces and LandVac tempered vacuum insulated glass.

COMPANY ACTIVITY

Manufacturer

SIMILAR COMPANIES

Qingdao REXI Industries Co., Ltd

No. 3 Building Resources Boya Plaza, Xiangling Road

Qingdao Shi

Shandong Sheng, 266071

China

Luoyang North Glass Technology Co., Ltd.,

No. 20 Binhe Road, High-tech Development Zone,

Luolong Qu

Luoyang Shi

Henan Sheng, 471003

China

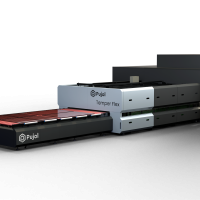

Hornos Industriales Pujol

Carrer del Pla, 108-110, Pol. Ind. El Pla

08980 Sant Feliu de Llobregat Barcelona

Spain

Beijing GreatDia Superhard Tools Co.,Ltd

No 5, Fu rong jie jia, Xi ma ge Zhuang village, Gao li ying town

Shun yi district

Shunyi Qu

Beijing Shi, 101300

China