Author: Pekka Lyytikainen | Glaston

Source: www.glastory.net

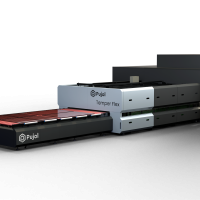

In practice, Glaston’s Tempering Autopilot means a smarter, more autonomous tempering process. It continuously monitors and adjusts key process parameters in real time, ensuring optimal furnace performance without the need for operator intervention.

The system uses advanced algorithms and sensor data to automatically fine-tune heating and cooling settings based on the glass type, size, and load. This results in more consistent quality, fewer rejects, and significantly reduced setup times between batches.

By minimizing manual adjustments and human error, the Tempering Autopilot not only improves efficiency but also ensures repeatable, high-quality results from batch to batch. It’s like always having an expert operator on duty, keeping the process stable and optimized. Moreover, Autopilot can dynamically react to changes in the process more quickly and accurately than a human operator could.

In short, Tempering Autopilot brings intelligence and automation to the tempering line, helping glass processors achieve better quality, higher throughput, and more predictable production.

Comments

It constantly tracks and modifies essential process variables in real-time, guaranteeing peak furnace efficiency without requiring input from the operator.

This is a fascinating look into Glaston’s Tempering Autopilot and how it revolutionizes precision in glass processing. The integration of smart algorithms and real-time monitoring really showcases how technology is streamlining industrial processes. It’s impressive to see how automation can maintain consistent quality while cutting down on human error and setup time — something Commercial contractors Fairfield and similar professionals would certainly appreciate when sourcing reliable, high-quality tempered glass for their projects.