Others also read

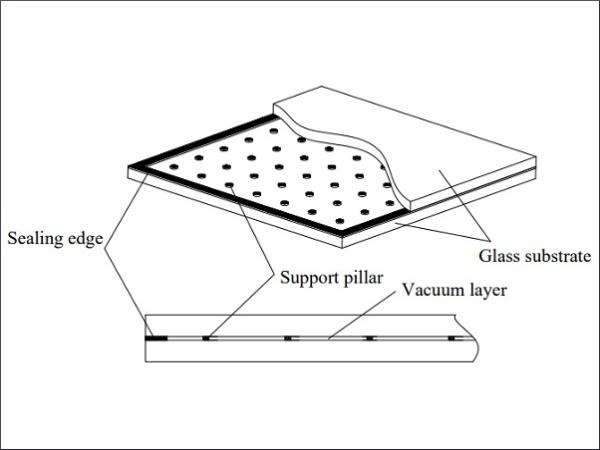

| Discover the perfect balance of sound and heat insulation with VIG multi-objective design optimization!

| Gain multiple benefits with upgrades to the glass laminating furnace

| Read the latest Glastory blog by Taneli Ylinen.

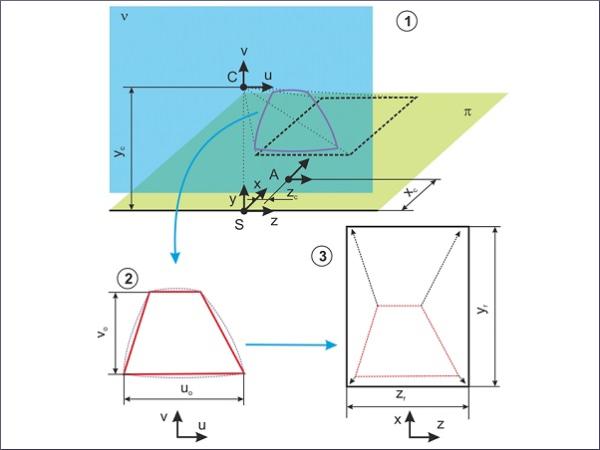

| Glass is reflective in large angles of incidence. Using this property for the detection of shapes is the basic goal of the research.

| End-of-life insulating glass units (IGUs) continue to follow a linear, wasteful path from renovation and demolition sites into landfills or low-value recycling.

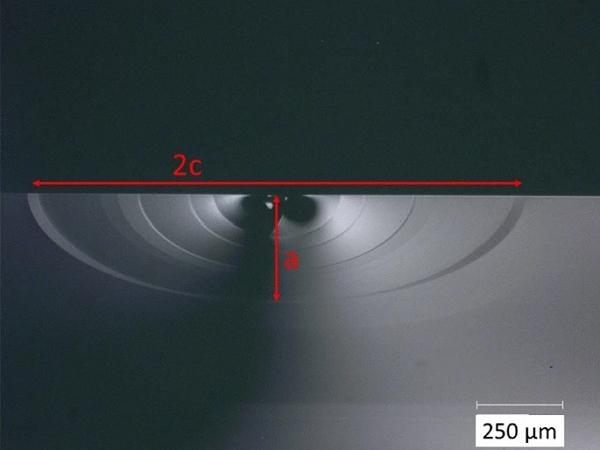

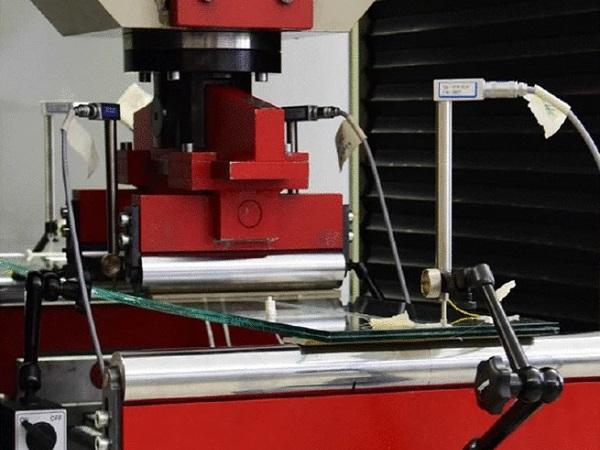

| In the present work, subcritical crack growth in soda–lime silicate glass is investigated under different environmental conditions.

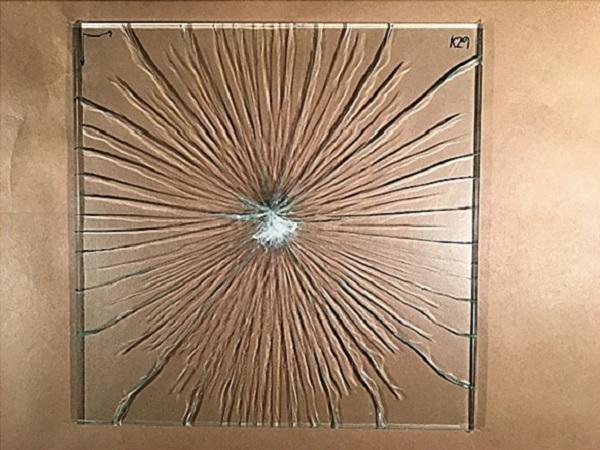

| Glass units are in demand in structural applications, however, the strength is challenging to predict.

| The current study aims to determine the probabilistic fracture strength of glass plates exposed to arbitrary loading and loading rates by a proposed rate-dependent strength prediction model (SPM).

| The paper presents testing of glass panels, static test and dynamic test by hard body impact.

| The study describes the results of the shear modulus of viscoelastic interlayers made of polyvinyl butyral and provides the basis to define and evaluate a model for the finite element analysis.

| In this third episode of the #AskGlaston flat tempering series, Taneli Ylinen deals with the commonly asked question of how to handle the issues with mixed production.

| In this post, we discuss what emerging designs require and how automotive glass processors can meet these requirements.

| The paper is focused on experimental testing of glass-to-glass connection using transparent adhesives.

| This Glastory blog by Kalle Kaijanen is dealing with the processing of high-strength / structural laminates.

| Within this research, two sets of real-scale laminated banister panels with the embedded connection were tested.

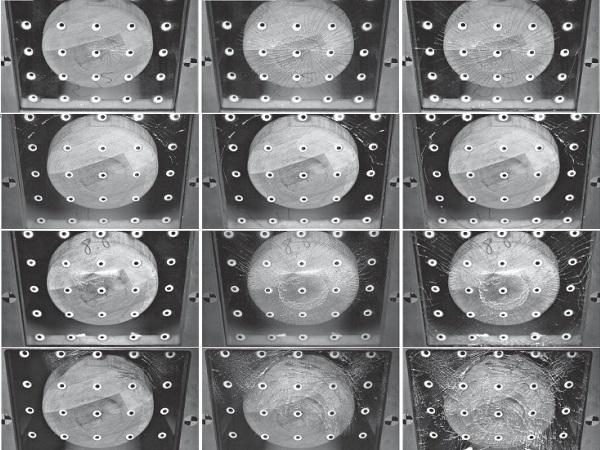

| The results of the classification of hail resistance classes for different materials for greenhouse enclosures are presented in this paper.

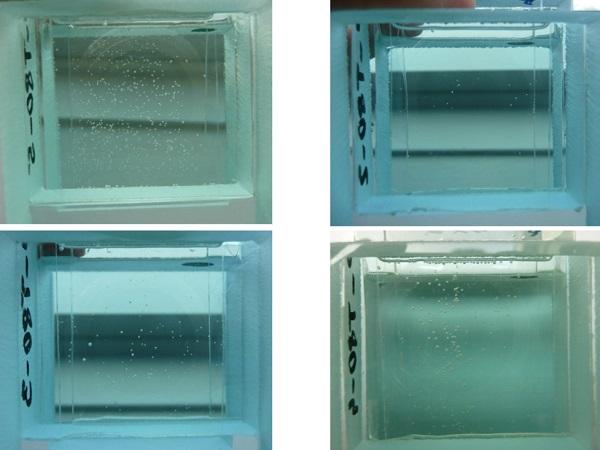

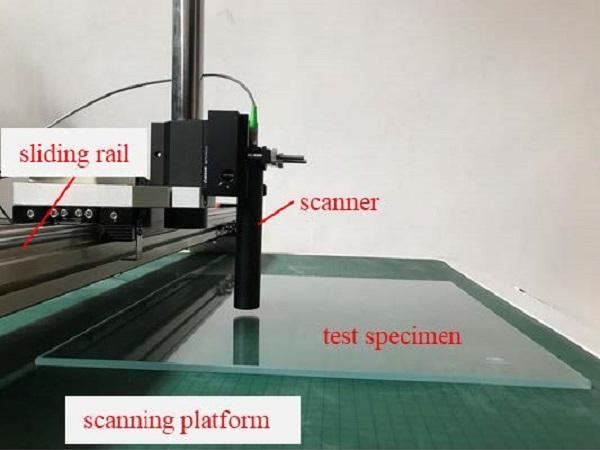

| This study aims to develop a non-contact stage-wise scanning method to extract 3D damage characteristics on glass surface, which can further facilitate the investigation into the associated influences on the flexural strength of glass.

| Color Depth is a material-based research project investigating the optical and structural properties of thick glass.

| The main challenge in the design of the duplex façade was the high aesthetical performance that the façade had to meet.

| In this paper, we present the development of an intrinsic parameter σQM characterizing the sensitivity of a coating (or configuration) to the quench marks.

| In the second episode of #AskGlaston Flat Tempering Series, we will talk about the new solution to estimate the stress level in glass – online.

| This first episode is devoted to the white haze phenomenon – one of the most asked about issues in the history of #AskGlaston.

| This latest Glastory blog by Miika Äppelqvist is dealing with the areas of the tempering process that can be improved to make operations more efficient.

| This paper focuses on a recently developed concept, in which glass is combined with timber to provide post-breakage strength and ductility.

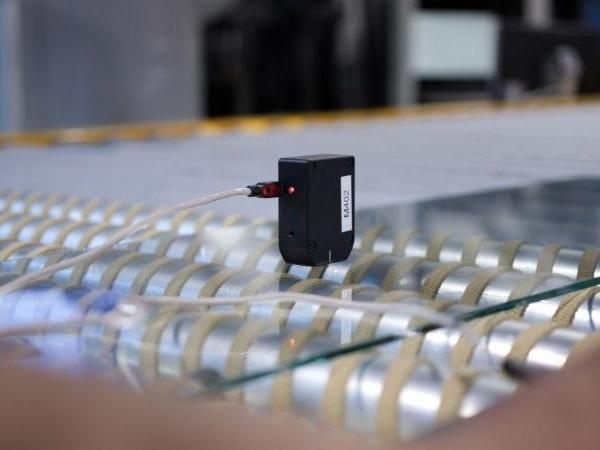

| Industry demand for impeccable glass quality has increased notably over the last years. Customer expectations run high, forcing glass processors to strive for ever-stricter quality control and ensure minimal rejection rates for finished products.