As the automotive industry evolves, the demand for more vehicle and driving-related information is growing year after year. Advanced driver-assistance systems (ADAS), autonomous driving systems (ADS) and other surround sensors mean more data to generate and display. What other trends are emerging from this, and how do these impact the display glass processing business?

When we look at automotive display trends, we notice only one direction – toward infinity. This comes both in the number of displays integrated within the vehicle and their actual size.

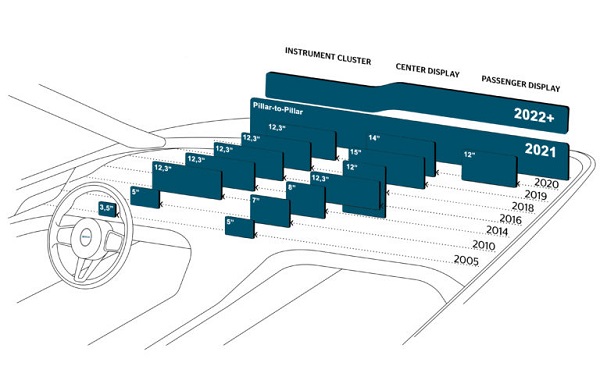

Over the last 15 years, the size of automotive displays has grown tremendously. They started off very tiny – but since then, they have only gotten bigger and bigger. They’ve changed many times, with several displays merging into one, resolution becoming higher and displayed information becoming ever more all-inclusive. Why pack the dashboard with numerous standalone displays if you can combine all the information needed into only one piece of glass?

Nowadays, automotive displays can even take up the entire dashboard of the car. The concept of this kind of in-vehicle display was presented by Mercedes-Benz this year in January.

Bigger size means more complex shapes

The need for very wide displays results in another of today’s market trends – shaped displays. By this, we mean more than just an elegant and simple curve. If you look at the dashboard of your own vehicle as an example, you will see the display has an extremely complex outer shape.

If your customers don’t ask for anything like that – just wait. Merging several smaller displays into one large and technologically sound innovative solution allows a brand to stand out from competitors. Especially in the premium vehicle market, this will soon be the next big thing.

For a glass processor, this means a whole range of things to consider to provide solutions that keep up with the trends.

Precutting process

The first is ensuring the best quality precutting process. Are you confident your shaping solution will be able to shape the input glass unit into whatever your customers require? Since display glass is expensive, you want to get the most out of your material. Ideally, precutting should match the final shape as closely as possible.

Shape cutting process

The next phase is cutting the actual shape of the glass on the precision cutting machine. Here, the break-out step is crucial. If you create chips here, you will not be able to grind them out – or you will need such a high grinding allowance that it will take ages.

Grinding and polishing process

In the grinding process, there are some things to improve, too. For instance, the latest preprocessing solutions grind and polish display glass on the same table without moving the glass. Because the glass is in the same position, the grinding of each contour exactly matches the previous one. This gives you the minimum grinding allowance with the highest cycle time.

Heat treatment and bending

Do you have the right heating technology for the glass bending process? For display glass, convection heating is the optimal choice. First, it can heat printed glass evenly, which is often needed for displays. Convection is also very helpful when working with delicate and very thin display glass.

Inventive automotive designers keep surprising us with new ways of embedding displays into interior surfaces. This is a great opportunity for forward-looking glass processors who are well-equipped and ready to support new ideas with the most advanced and progressive offering.