This paper was first presented at GPD 2023.

Link to the full GPD 2023 conference book: https://www.gpd.fi/GPD2023_proceedings_book/

Authors

- Javier Sanchez-Gil - Cristacurva, Houston, USA

- Gabriela Davila - Cristacurva, Guadalajara, Mexico

- Patrisia Yanez - Cristacurva, Houston, USA

Abstract:

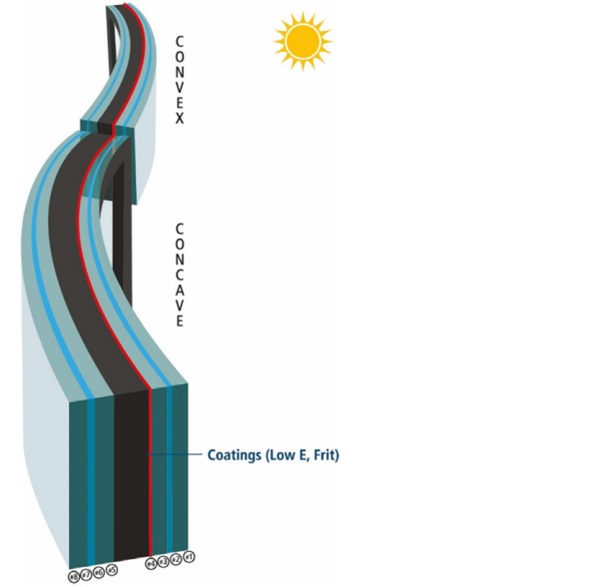

Curved glass is a component that plays a central role in the aesthetics of heightened designs and iconic buildings. Curved glass is fundamental in advanced architecture which incorporates a magnitude of glass with organic forms throughout these cutting-edge design structures. Pushing the limits of innovation and design possibilities requires continual technological development in glass fabrication techniques in order to keep up with the latest aesthetics, safety, structural, and performance requirements. One of the key components within these requirements is preserving uniformity in aesthetics and performance when a high thermal-performing or decorative curved glass application is required for convex and concave curves. The following showcased projects demonstrate examples of how advances in technology and know-how have made it possible for curved glass to keep the same aesthetics and thermal performance in undulating facades where the coatings are to remain on the same surface, typically #2 or #4, regardless of whether the curve is concave or convex.

Introduction

Color uniformity is an integral part of any architectural design concept. Therefore, any modification pertaining to the placement of coatings (Low E’s, frits, and printed patterns) may overthrow the purposed vision and create a misjudgment of the visual intent. Interfering with the fluidity of the aesthetics is not something an architect wants to encounter when designing any structures.

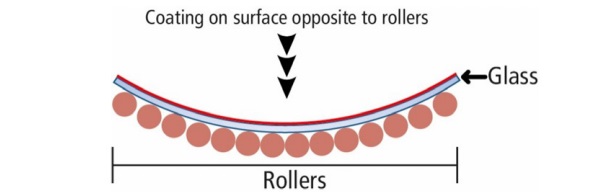

Only until very recently, curved tempered glass had been restricted to a unidirectional curving technology because the coatings are to be maintained away from the oven’s rollers, see drawing below.

This limited the design of curved glass façades that required coatings (Low E’s, frits, and printed patterns) to only convex applications - where the curve of the glass would face outward of the building keeping the coatings on the interior. If the architecture of the structure called for a concave curve, the coating had to be moved to surface #3, #5, and so on, resulting with loss of solar performance and altered glass aesthetics. Architects had to settle and work with this technological constraint.

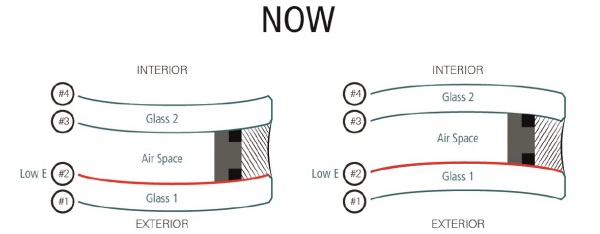

Recent developments have enabled the possibility of having curved glass in concave applications with coatings (Low E’s, frits, and printed patterns) on surface #2, #4, and so on, making this new technology a fundamental process. With color uniformity now available, the integrity of the scope is preserved reducing biased color renditions and only enhancing the intended way of the unique conceptual design. Solutions to undulating facades, or concave curves, that need to match performance and appearance with the rest of the glass on the façade have become a reality.

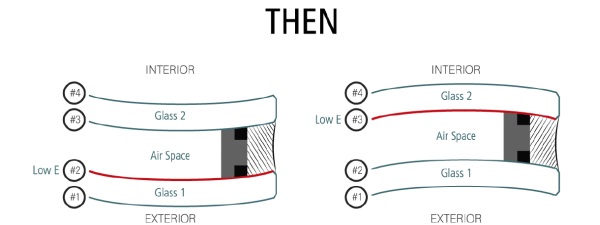

Aesthetic Differences

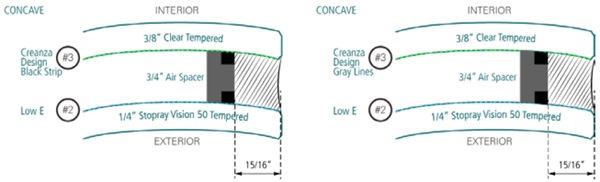

The following illustrations show how coatings had to be placed on uneven surfaces (#3, #5, etc.) when the glass was curved and installed with its concave surface facing the exterior of the building.

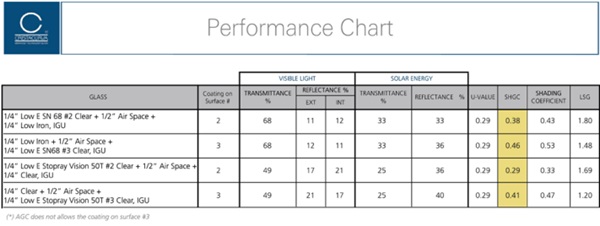

Performance Differences

The following performance chart shows two different glass coatings and difference in performance when the coating is placed on surface #2 or #3. As it is possible to see, the solar heat gain coefficient (SHGC) is considerably lowered when the coating moves from surface #2 to #3. In the case of SN68 there is a 19% loss in performance and up to 30% in the case of Stopray Vision 50. It is important to note that AGC, the manufacturer of the coating Stopray Vision 50, indicates against placing this coating on surface #3. As it is possible to see, not only do the aesthetics become uniform using the curved concave new technology, but also the solar performance of the units, which would otherwise be diminished when coatings are transferred to an inner glass surface. The following are just two examples of projects that have used this breakthrough state-ofthe-art technology to create beautiful curved and undulating facades, achieving uniformity in the glass aesthetics and the required solar performance.

2100 Penn Corporate Headquarters An undulating façade with reflective Low E glass.

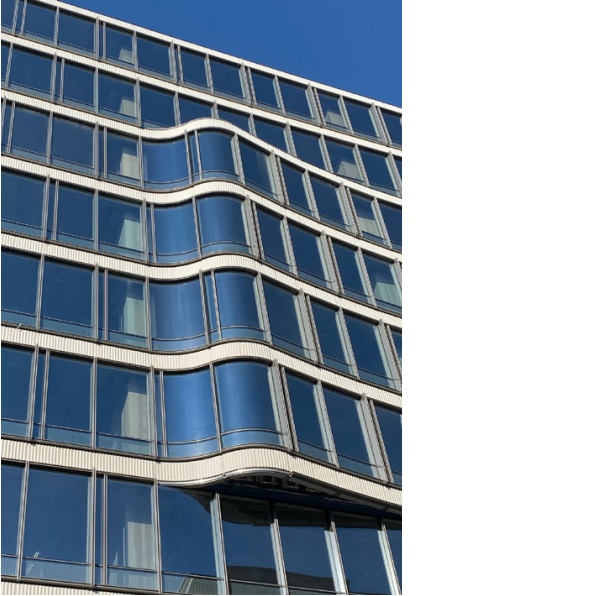

The façade of a newly constructed corporate building located at 2100 Pennsylvania Avenue, in the heart of Washington DC, is a very fitting example of a façade with curved glass that undulates around the building creating a stunning architectural feature. Designed by the renowned architectural firm Pelli Clarke Pelli, the mixed-use 42,000m2 building located right next to George Washington University is targeted to be LEED Gold development.

Considering that the building is predominantly visible along Pennsylvania Avenue, and adjacent to a small yet beautiful park owned by the National Park Service, the architects created a striking undulating floating effect with the curtain wall design along the 3 main streets it faces. The unique gracefully designed façade is a key feature in making it the new iconic building in Washington DC, and is reminiscent of other curved and undulating world icons such as Flatiron in New York or Casa Mila in Barcelona.

According to the architects, “the large doubleheight projecting bays animate the façade like the surface of a waving flag and enhance visual connections between the neighboring streetscapes and workplace interiors.” To accomplish the architectural intent, the undulating, curved glass needed to keep the coating on the #2 surface regardless of it being concave or convex. Up until now, when an undulating façade was designed and a coating required, the coating consequently had to be moved to the 3rd surface of the glass substrate in the concave sections of the façade (please see charts #2 and #3). Changing the surface where the low-e was located enabled the glass to be fabricated with the technology available at the time; however, the solar and thermal performance suffered. In the case of a more reflective glass type, like the one selected for this project, the aesthetics were highly compromised as the concave glass acquired a completely different appearance.

Utilizing the newly-developed “curved, tempered, concave” technology, the glass fabricator curved a large amount of highperformance glass pieces, using a semi reflective Low E glass product and assembled them into IGUs. The project was challenging, not only because concave and convex glass were side-by-side, but also because there were many different radii, requirements for thicker air spacers, and larger-than-normal secondary seal. Initially the architectural team was looking for a 6’ 1” radius which was on paper, too tight for the curved concave technology. However, through additional research and development, the glass fabricator was able to meet this requirement and actually achieved a tighter radius, down to 5’ 7”. Worth noticing on this project is that the silicone depths were also thicker than normal and designed to meet more stringent wind loads.

Production of the panels was completed in the time required, shipped to Canada to be assembled into a unitized system, and then installed at the job site in Washington DC. The aesthetic results achieved were not only consistent throughout the manufacturing process, but also stunning – bringing to life the architect’s vision for the building.

1101 Chestnut

A curved concave façade with oversized reflective Low E glass.

The winner of Philadelphia Business Journal’s top honor: Best Real Estate Deal of the Year, is a beautiful 19 story building designed by Ennead Architects from New York City. The building is located in Center City, Philadelphia, near downtown, and will house many of Jefferson Health's Specialty Care medical services.

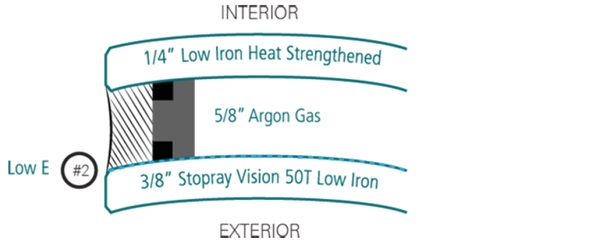

The façade offers movement and beauty through the use of curved concave glass. Glass units span up to 5.64m (222”) using combinations of different glass thicknesses, depending on the unit location. The façade includes different flat glass configurations that are adjacent to the curved concave units, in order to create a textured flowing façade. The curved glass required the same Low E product as the adjoining flat glass. As such, the architects chose low iron glass and a coating that could be curved.

The design process included a great deal of collaboration between the architects, consultants, and glass fabricator early on. The goal of these discussions was to better understand the curved tempered concave technologies, and to determine what design possibilities were available with the new technological developments. Through a collective process, the group determined the radius of the units that would gracefully connect the flat pieces in a curvilinear way. It was imperative that the design team and the glass fabricator worked together in order to ensure an aesthetically-pleasing design that could, indeed, be fabricated.

In order to verify the color and general aesthetics of the concave curved glass, the glass fabricator produced 3 different mock ups that enabled the design team to better visualize the curved concave effect, and how the general aesthetics of the curved Low E glass would enhance the façade.

The project includes approximately 800 units of varying sizes, the largest being 1.95m (77”) x 5.64m (222”). The considerable size of the curved concave IGUs and the large volume, was a production and logistical challenge that the glass fabricator, in coordination with the glass installer, successfully resolved.

At the start of the fabrication process the construction and design teams visited the glass fabricator’s facility to inspect units and to have a better understanding of the quality program the fabricator followed. Different steps of the process were reviewed, including the crating and shipping of these very large units to their destination in Pennsylvania. The design consists of the curved units being assembled onto a sophisticated unitized curtain wall façade system. The installation of this beautiful curved concave glass façade began in the fall of 2021 and finished in September of 2022.

Conclusion

The curved glass fabrication of these two projects exemplifies the everchanging design requirements demanded of glass in modern architecture, and how newer technologies and timely coordination between the architectural and glass-fabrication teams enable solutions to these new design challenges.

The possibility of placing coatings, Low Es, frits, and other, on any surface regardless of the glass being curved convex or concave is an architectural breakthrough and a game changer. This new technology gives architects a free rein when it comes to designing organic and flowing glass walls, keeping coatings on the same surface regardless of whether the glass is curved in a convex or concave way. Aesthetics and performance are kept consistent and uniform, allowing for beautifully designed and environmentally friendly buildings.

The prospect of uniformity in aesthetics and performance, now available, is a win-win situation that will transform tomorrow’s architectural landscape.