Date: 26 November 2020

With more than 135 years of experience, HORN® has been the specialist and expert in the field of the construction of glass melting furnaces for many years. However, this has changed and HORN® is now one of the industry leaders in the implementation of turn-key projects.

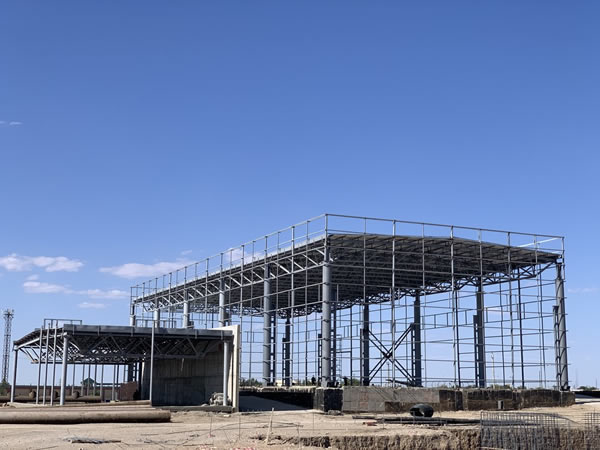

HORN® Glass Industries supplies an all new float glass plant with a production capacity of 250 tons of glass per day for company Zarafshon Oyna LLC. in Zarafshan, Uzbekistan. HORN® has been equipping the country's first float glass plant on behalf of Zarafshon Oyna LLC. since May. HORN® is in charge of planning, delivering and commissioning all technological equipment in Uzbekistan's first float glass plant, which will be handed over to the customer in the summer of 2021. "We're extremely proud to be implementing this major project as a turnkey solution" says Markus Frank, Deputy Director, Glass Plant Technology at HORN® Glass.

Since extraordinary times call for extraordinary commitment, a lot of HORN® employees are currently stationed more than 5000km from their original workplace in the city of Zarafshan, about 670km west of the capital city of Tashkent (Uzbekistan). The situation that the Central Asian country currently has no float glass production of its own and therefore has to import glass sheets from abroad will soon change.

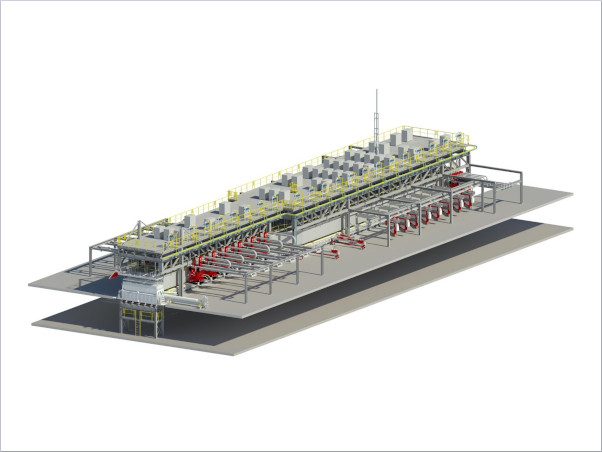

HORN® will provide an impressive scope of supply: planning the melting tank, tin bath and annealing lehr and delivering all the refractory material, the firing system for natural gas and diesel oil, batch and cullet chargers, coolers, stirrers and measuring as well as control technology. The tin bath with its associated technological equipment including a shield gas mixing station as well as the entire annealing lehr and automation system for the hot end will also be supplied by HORN®.

With regard to total automation, HORN® developed a special concept for the top rollers that allows the tin bath to be integrated in the process control system. Zarafshon Oyna LLC. will be using the HTRM-S (suspended) top roller. For all the machine technology, HORN® relies on Siemens products. HORN® Glass, as a general contractor for this project, has collaborated with leading European companies specialised in different fields.

With regard to the future, experts at HORN® Glass recommend an expansion on the same premises so that processing and finishing can also be performed in Uzbekistan. In doing so, the customer will be able to market architectural and automotive glass directly from the factory, both at home and abroad and consistently promote the "Made in Uzbekistan" image for float glass products as well.

600450

600450

Add new comment