Date: 25 June 2024

This installation marks the third such Osprey system for UPG, reinforcing the company’s commitment to utilizing advanced technology to enhance its production capabilities and quality.

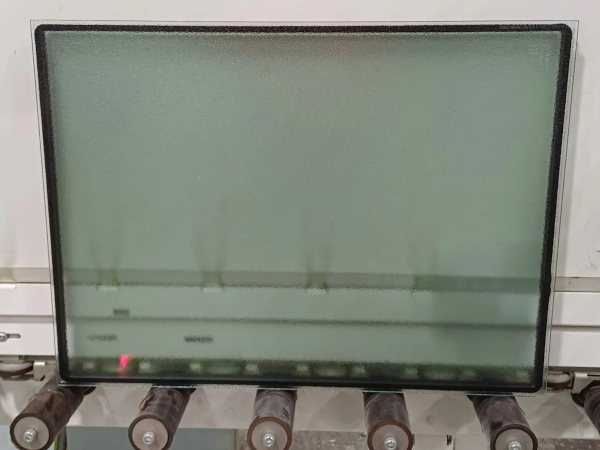

The Osprey 10 Complete is celebrated for its precision and efficiency in glass production, ensuring consistent, high-quality output. This state-of-the-art technology aligns with UPG’s dedication to meeting the highest standards in the industry and providing superior products to its customers.

Cory Brown, Director of Operations at United Plate Glass, shared his enthusiasm for the Osprey 10 Complete and its impact on the team and production quality.

“I love the Ospreys, but what I love even more is that my operators all love the Ospreys. It’s been paramount to our improved quality,” said Brown. “The Osprey 10 Complete has not only streamlined our processes but also significantly enhanced the quality of our products, thanks to the ease of use and reliability that our operators experience.”

The addition of a third Osprey 10 from LiteSentry-Softsolution is a testament to UPG’s ongoing investment in cutting-edge technology to maintain its competitive edge. This addition aims to boost production efficiency, ensure top-tier quality, and meet the evolving demands of UPG’s diverse clientele.

United Plate Glass is dedicated to upholding a tradition of excellence through continuous improvement and innovation. The integration of the Osprey 10 Complete at the North Carolina facility signifies another milestone in UPG’s commitment to operational excellence and customer satisfaction.

600450

600450

Add new comment