Date: 10 January 2017

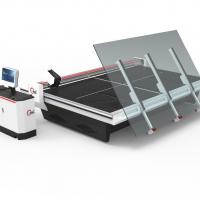

Successful restart of two Illinois lines! The Grenzebach float glass cutting line picks up the endless glass ribbon at the cooling station to transport it through the quality inspection to the fully automated cutting and snapping area after which the single glass sheets are being stacked.

Grenzebach’s customized cutting and line optimization, in accordance with the process controlling, is directly linked to the Fuyao ERP system (inventory control system) which provides maximum glass production.

The glass sheets, which are being separated on the line, are transported to twelve robots, which pick the sheets off the line "on-the-fly". The robots which are located on the left and right side of the line synchronize to line speed, pick up the glass sheets with suction frames and drop them onto the racks ready for shipment to the customer.

Also, now the "pick-on-the-fly" robots feature the new "dual pick" technique which allows for two sheets to be picked up at the same time. The snapping and removing of single sheets on the main line completely eliminates the need for side lines.

Due to the high flexibility of the equipment consisting of cutting systems, snap and chevron roller conveyors and robots, both Fuyao lines in Illinois can produce a wide range of sheet formats.

Since the lines produce glass 24/7 all year round, it takes an exceptionally reliable partner – and Grenzebach can offer just that and much more with over 50 years of experience in the glass industry and having implemented similar lines at Fuyao in China.

600450

600450

Add new comment