Date: 19 November 2024

Founded in 2000, South Star Glass Limited has emerged as a leading force in the glass processing industry, consistently providing top-quality glass products across diverse markets. From its roots in South China to its expanding presence in Hong Kong, Macau, Southeast Asia, and Australia, South Star Glass has built a reputation for excellence. Today, it stands as the most advanced and highest-capacity independent glass processing plant in the region.

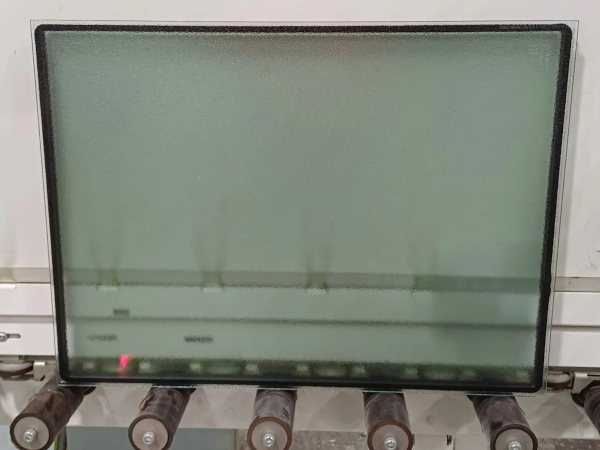

At the heart of South Star Glass’s success lies its commitment to precision, efficiency, and continuous improvement in production processes. To ensure the highest standards of product quality, the company has implemented cutting-edge technologies that enhance both its manufacturing capabilities and inspection processes. One such technology is the vertical LineScanner, an automated system that meticulously checks the surface quality of finished insulating glass (IG) units, laminated glass, and single-pane glass.

The LineScanner plays a pivotal role in South Star Glass’s quality control process. Unlike manual inspection, which can be subjective and prone to human error, the LineScanner provides objective, accurate reports of any surface defects. This helps ensure that each piece of glass meets the company’s stringent standards before it reaches the customer.

In addition to the LineScanner, South Star Glass utilizes the Osprey Complete, an advanced system for measuring anisotropy and distortion in tempered glass. This technology has become indispensable in the company’s operations, according to Mr. Li Baiyu, the production manager at South Star Glass.

He explains, “With an Osprey, operators can efficiently access real-time quality data for tempered glass, enabling immediate adjustments to production parameters and ensuring consistently high-quality output. The LineScanner precisely detects glass surface defects, delivering objective and accurate inspection reports that elevate the standard of quality control..”

The implementation of these systems has led to a significant improvement in production efficiency and product quality. By automating key inspection processes and enabling precise adjustments, South Star Glass has not only reduced the likelihood of defects but also enhanced its ability to respond to potential issues promptly. This focus on continuous quality improvement has been a driving force behind the company’s growth and success.

With cutting-edge technology, a commitment to innovation, and a focus on quality, South Star Glass Limited continues to set the standard for glass manufacturing and processing in the region.

600450

600450

Add new comment