Date: 16 September 2024

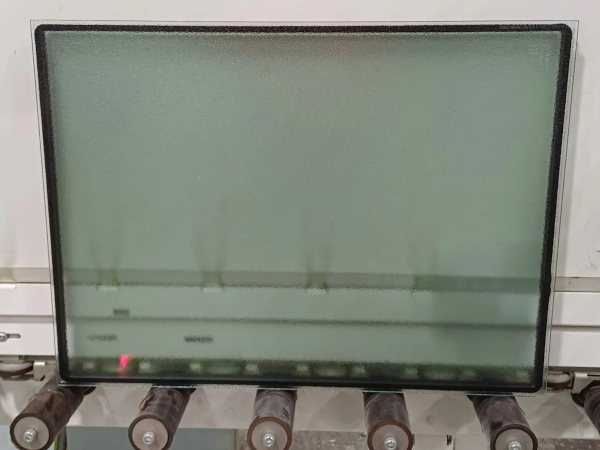

Eyrise has concentrated on liquid crystal display technology, developing a new, reliable, and robust solution for modern interior and exterior building glazing. Their liquid crystal glass, branded as eyrise®, is manufactured at their facility near Eindhoven, Netherlands. This production line is unique and the first dedicated to architectural liquid crystal glass, producing panels as large as 3.5 meters—a world record.

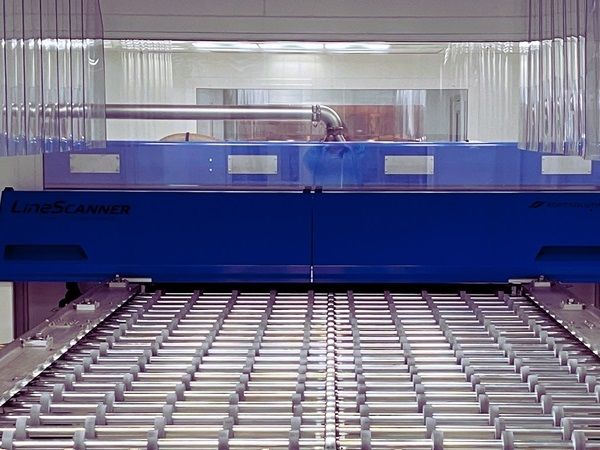

Ronald v.d. Heuvel, Project Engineer, stated: “I am pleased to confirm the successful and timely delivery of the Softsolution LineScanner to the eyrise dynamic liquid crystal glazing facility. The project was completed within the agreed timeframe and budget, demonstrating exceptional management and commissioning. The initial results post-implementation have been very promising, with notable improvements in operational efficiency, leading to increased productivity and reduced downtime.

Additionally, we anticipate incorporating further functionalities of the Softsolution LineScanner beyond our initial requirements, which will enhance product quality monitoring. Overall, the successful delivery and early positive results from the Softsolution LineScanner have set the stage for continued operational improvements and quality optimization.”

600450

600450

Add new comment