Date: 21 December 2018

In 2017, fire crews in England attended over 560,000 incidents, 34% fewer than ten years ago.

Of those, only about 170,000 were fires, and over 220,000 were false alarms.

Every year in the UK more than 20,000 non-residential fires are reported, with many of those happening in our workplaces.

While there are a large number of reasons why fires start, many incidents could be avoided if people better understood and managed the most common causes of fire.

While the overall incidence of workplace fires continues to fall, they do tend to be larger and more complex, not only potentially posing a risk to life but to the continuity and survival of the company affected.

Preventing workplace fire loss requires knowledge of both the underlying ignition risks and, if fire does break out, the reasons why the fire might spread.

The main element that then determines the severity of a fire is the availability of a fuel load – the combustible materials that a fire needs to develop and grow.

Faulty electrics are the biggest cause of workplace fires and workplaces are legally obliged to properly maintain all electrical equipment and to conduct Portable Appliance Testing (PAT) at least annually.

These tests ensure that electrical goods are fit for purpose and remain in good working order. Failure to test annually is therefore not only a fire risk in itself, but could result in legal penalty.

What’s also needed is a comprehensive fire safety risk assessment, particularly vital if combustible and flammable materials are used in the workplace.

That assessment will then guide a fire safety plan to ensure the most appropriate storage, handling and disposal of flammable materials.

Again, failure to comply with the fire and safety regulations is a fire risk in itself and, again, could result in prosecution.

But it’s not just complacency that’s the main fire risk, because accidents can happen – for example, an employee spilling liquid onto electrical equipment.

What’s then crucial is that the workplace has sufficient and appropriate fire safety equipment, and that staff are fully trained in their use.

But while accidents can and do happen, a bigger threat is negligence because, in the event of serious incident, the company concerned may lose any right to insurance recompense, leading inevitably to financial difficulty and possible closure.

While every company must have a named person responsible for fire safety, everyone in an organisation also has personal responsibility, because everyone must be aware of fire risk, proper procedures, and what to do in the event of fire.

As we also constantly point out, one of the main lessons for building designers and owners is not simply to incorporate passive and active fire systems, but to look at the whole building’s capacity to withstand a fire.

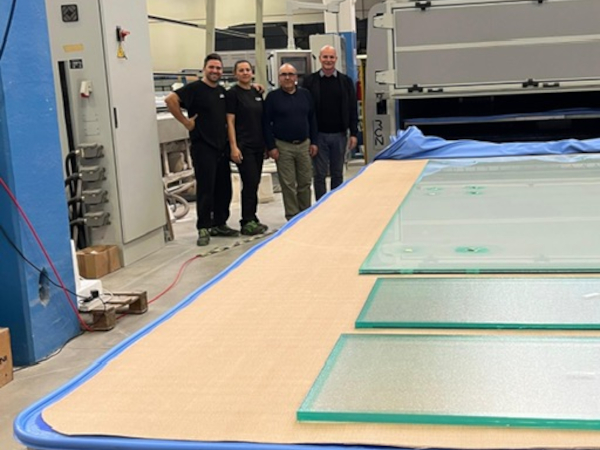

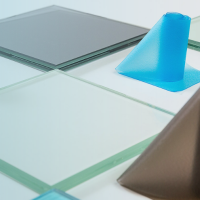

That’s why advanced glazing systems are so important, either for the exterior envelope of a building or for internal screens and fire doors, providing up to 120 minutes of protection against the spread of fire, smoke or toxic gases.

Advanced glazing systems also do one additional thing. By containing the fire, they minimise damage to that company’s workplace and better provide continuity of operations. It is, if you like, an investment in peace of mind.

600450

600450

Add new comment