Date: 20 December 2023

In a world where environmental consciousness is paramount, industries are under increasing pressure to reduce their carbon footprint. At the forefront of this movement, POLFLAM, a producer of state-of-the-art fire-resistant glass, has made a bold commitment to sustainability by introducing the world’s first POLFLAM GAIA low-carbon fire-resistant glass.

Collaborating with PILKINGTON, part of the NSG Group, we’re proud to introduce a low-carbon alternative for regular fire-resistant glass. By combining our unique hydrogel interlayer technology with Pilkington Mirai™ low-carbon float glass with 50% reduced embodied carbon compared to standard float glass, pioneered through a combination of alternative fuel, high recycled glass content and green electricity sources, we are able to offer the market low-carbon fire-resistant glass with up to 65% less embodied carbon compared to regular fire-resistant glass products, depending on the fire-resistant classifications.

The advantages of our low-carbon fire-resistant glass are multifaceted, with sustainability taking center stage. Notably, it contributes significantly to the growing demand to reduce the CO2 e footprint of buildings and constructions without compromising fire safety or light transmittance. Moreover, our low-carbon glass aligns seamlessly with prestigious certifications such as LEED, BREEAM or DGNB green building labels, providing assurance that our product is at the forefront of environment-friendly construction practices.

What truly sets POLFLAM apart and positions us as the pioneers in the market is our groundbreaking fire-resistant glass production technology. The core of our fire-resistant glass consists of two thermally toughened safety glass panes with a colourless hydrogel interlayer in-between, produced according to our own proprietary formula.

What distinguishes our products, is that to achieve higher fire-rated classes, we can increase the thickness of the hydrogel interlayer without adding extra glass panes, unlike regular multi-layer fire-resistant glass products.

This exclusive approach not only ensures state-of-the-art properties such as the highest light transmittance and lowest weight for fire-rated classes from EI60 and above, but also achieves this with up to 35% lower embodied carbon for our regular products. Combining this technology with Pilkington Mirai™ low-carbon float glass as the substrate sets an unmatched new standard for reducing the CO2 e footprint of fire-resistant glass.

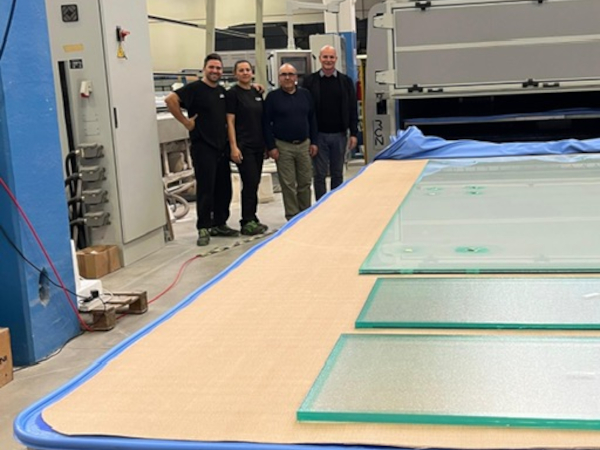

Recently, POLFLAM has successfully finalized their pilot run with the production and testing of the first low-carbon fire-resistant glass panes to ensure its quality and performance using Pilkington Mirai™ 6 mm low-carbon float glass. The next step s to expand our complete product range including Insulated Glass Units. In the meanwhile, our LCA (Life Cycle Assessment) and EPD (Environmental Product Declaration) for this new product is being prepared by a third-party institute to confirm the lowest carbon footprint on the market. The new EPD for POLFLAM low-carbon fire-resistant glass product is expected to be ready end of Q1 2024.

This cutting-edge product exhibits no compromise in performance, quality or aesthetic appearance and will be available for the whole range of products from EI15 up to EI180. Stay tuned as we embark on this transformative journey, shaping the future of the glass industry.

600450

600450

Add new comment