Date: 26 October 2009

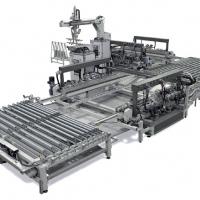

The new owners relaunched the company, strengthening its prominence and worth in the leading global markets. Product development and sales success followed quickly and in a kind of natural progression, leading to the brand’s current position of strength in the tempered glass accessories sector.

The new owners relaunched the company, strengthening its prominence and worth in the leading global markets. Product development and sales success followed quickly and in a kind of natural progression, leading to the brand’s current position of strength in the tempered glass accessories sector.

With 50 years of history behind it, and twenty of those under new management, Nuova Oxidal continues its manufacturing adventure, in preparation of handing off the business baton to the next generation of the Baroni family.

In keeping with the imminent power shift to the latest generation, we wanted this interview to be a first-person account of the personal and professional experiences that many Italian family-owned and operated businesses will identify with.

Elisa and Christian, Nuova Oxidal was established about 20 years ago, based on the experience gained with the original Oxidal: almost a refounding, with the new property, that led to a profound transformation and revitalization of the company. Now that the baton has been passed to you, what feelings of responsibility do you have toward the family business?

Yes, Nuova Oxidal grew out of our parents’ acquisition of Oxidal on October 1st, 1990. Next year will mark our 20th anniversary. At the time of the acquisition, the company was more or less on its last legs. In the years following the great post-war boom, the previous owners had lost interest and the desire to expand the company, which, as time went by, had begun to fall into decline. Purchase of the company by our parents signaled its rebirth, in terms of both sales and productivity. Initially, while we were busy studying, we followed the development from the sidelines; then we entered the business and now we can say we grew up with it. Twenty years ago, Oxidal could have been defined as a small metalworks business. Today, from a production standpoint, Nuova Oxidal is in the vanguard, with highly mechanized systems, we have come of age in terms of sales, recognized in Italy and abroad. Our sales have increased ten times during this time. Of course, there’s a lot of work ahead, so there’s not much we can do except continue along the path taken by our parents, trying to improve the company as we go.

A knack for doing business can also be inherited, but quite often the preparation required to take the reins of this inheritance is very challenging. How did you prepare for this job?

Handing off the proverbial baton was the culmination of a long journey that, at times, even included some contrasting ideas, but we think that’s to be expected. It’s hard to separate the role of business executive from that of child or parent; add to that the differences between generations… Anyway, our parents helped us, and shaped our learning with their vast knowledge of glass and its uses, giving us a better understanding of our industry and making it possible for us to gain the expertise to be recognized as consultants. More and more often our customers come to us for technical advice and this is the proof that our parents’ teachings were invaluable to our personal growth and that of our company. But we don’t think our education is over yet; we are young and we certainly have a lot more to learn. We’ve matured day by day with the company and hope to continue to grow with it.  Would you define your contribution to the vitality of the company the extension of an experience that produced positive results, or do you feel a call to explore new paths?

Would you define your contribution to the vitality of the company the extension of an experience that produced positive results, or do you feel a call to explore new paths?

It’s hard to say. What was done up until now produced positive results but, naturally, you need to be able to keep pace with the times, so the exploration of new pathways cannot be ruled out. During the last few years we took a new direction by adding several product lines intended to meet the needs of the exhibition design and furnishings industry, but we also expanded and updated our existing product line. We have some other internal development projects in the works and what we think of as educational-training projects in mind, too, but for now it’s better not to disclose too much about them.

Everyone, especially the business leaders who’ve been at the top for a long time, says the current economic crisis (which we hope is coming to an end) was the worst in terms of size and consequences since the end of WWII. Do you feel lucky or unlucky to have encountered this crisis at the beginning of your career?

Let’s say we feel fortunate to have experienced it in a period of sound corporate health during which it was possible, thanks to decisions made in the past, to face the crisis without excessive worries. Of course, there were lots of problems, but we managed to adapt to the situation, and it certainly is a period we won’t forget. On the contrary, it has taught us to be much more careful in the future.

In your opinion, what were the strongest attributes of the preceding generation and what were its faults?

Their strength, undoubtedly, is that of having believed in our company, bringing it to the degree of success it enjoys today; the weakness is perhaps that of not knowing how to fully manage the expansion phase, but we also understand, since we worked through it alongside them, just how hard it was to keep up with the organizational aspects and details that go with annual growth rates of 20 to 30%.

Nuova Oxidal’s initiative with the Polytechnic University of Milan (organization of a specialization studies course for the design of temporary spaces) offers 30 architects per year the opportunity to hone their skills by directly confronting the needs of the market. In your opinion, is there still a substantial distance between the academic world and the world of business in Italy, compared to the other industrialized nations?

Yes, we feel there’s a considerable distance. In Italy, especially, much more could be done, particularly by working with the trade associations, which have the economic and technical means to support training and educational programs. But, unfortunately, not many are moving in this direction, overlooking (in our opinion) a fundamental aspect. In the glass industry, training is essential. Glass is a material that can be used in an infinite number of ways and in many different fields, with low environmental impact, because the material can be recycled. The development of glass leads to the development of our industry, however, all to often, we run up against a certain lack of awareness or poor use of glass. This leads designers to avoid using it. Unfortunately, a piece of glass that breaks generates negative publicity, while in most cases breakage is caused by errors in measurement or installation. Even in the area of regulation, we feel vast improvements could be made. The regulations are there but often they are hard to interpret or hard to find. Here, too, we are working to draft regulations for metal-point suspended structural glazing, but there are still many other topics to be addressed.

We hope that in the near future the associations will also develop activities like those offered by the Polytechnic University; but, for the time being, the burden is still being borne by private enterprises.

One last question, obvious but nonetheless valid: How are you preparing for 2010? Will it be the year of the turnaround?

The year 2010 will mark our 20th anniversary and we are working on a new corporate image. We’ve planned some events that are still in the design stage, so we can’t say much about them.

Add new comment