Date: 30 August 2024

Introducing Corner Overhang and Break Detection: Precision on Every Edge!

At LiteSentry-Softsolution, innovation is a continuous pursuit. The team of experts has been diligently working to push the boundaries of what’s possible. Today, they are excited to unveil a new feature that will revolutionize the inspection of glass edges.

What’s New?

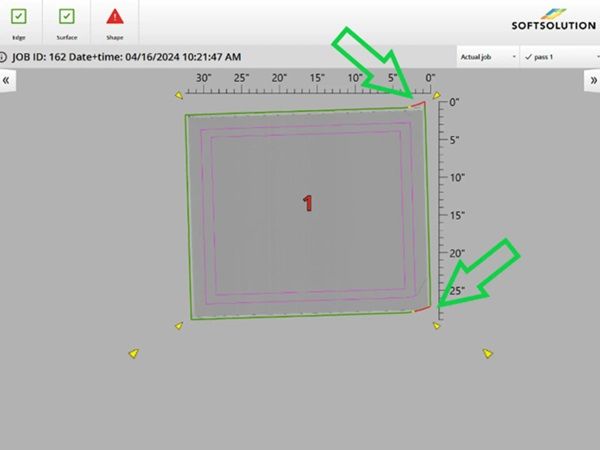

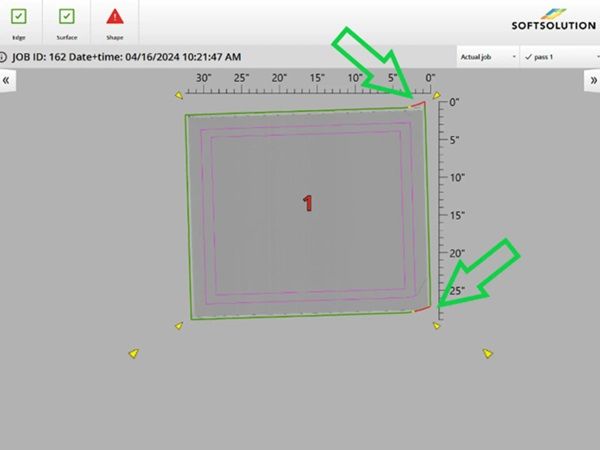

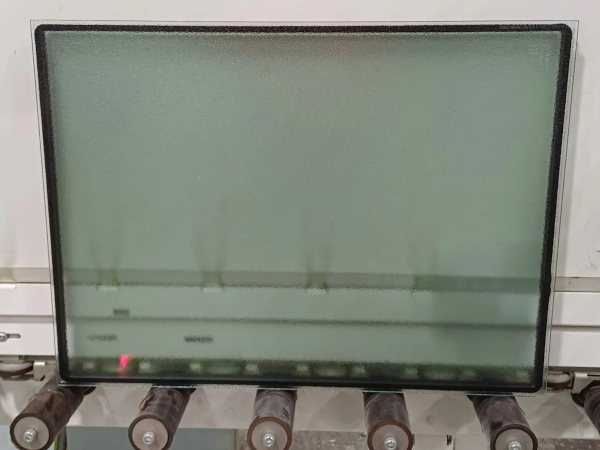

The latest development empowers the LineScanner to automatically detect corner overhangs (flares) and breaks (broken corners) with exceptional accuracy. Whether it’s a subtle overhang or a critical break, the advanced algorithms ensure that no flaw goes unnoticed. This translates to higher precision, fewer defects, and an overall boost in the quality of products.

Why This Matters:

- Enhanced Accuracy: The new feature ensures that every glass edge meets exact standards, eliminating missed imperfections.

- Increased Efficiency: Automated detection reduces the need for manual inspections, saving valuable time and resources.

- Improved Safety: Early detection of breaks helps prevent potential hazards in the production process.

This enhancement provides the reliability and confidence needed to consistently deliver top-quality products, reaffirming LiteSentry-Softsolution's commitment to helping customers achieve excellence.

Ready to Experience the Future?

This feature is now available for all LineScanner systems. For more information on how this update can benefit operations, the sales team is ready to assist.

600450

600450

Add new comment