Photo source

Softsolution – LiteSentry

Date: 24 April 2023

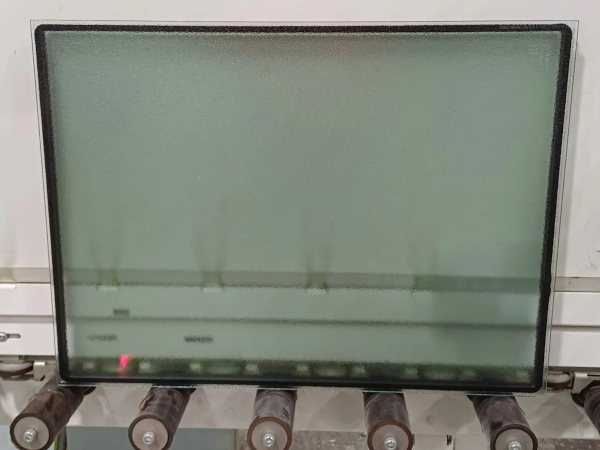

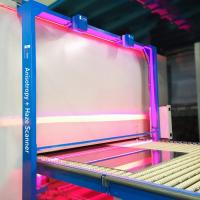

New dimensions and standards are built at the location in Waidhofen/Ybbs.

The Softsolution – LiteSentry team is currently building by far the largest LineScanner for a European customer.

With a remarkable length of 3400 mm, the vertical scanner proves an unprecedented scale for the automated quality inspection of glass.

600450

600450

Softsolution – LiteSentry

2023-04-24T07:30:00

Largest LineScanner sets new standards for glass quality control

glassonweb.com

Add new comment