Date: 23 February 2018

Affiliated to a national defense university, the research team has undertaken many military related R&D projects. About half a year ago, they started on a project to test the mechanical properties of the missile engine propellant.

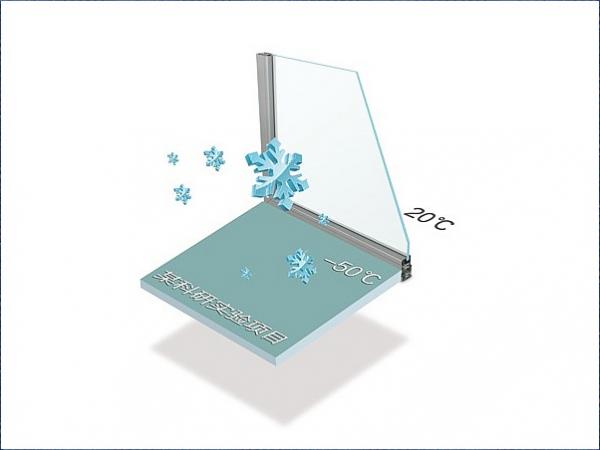

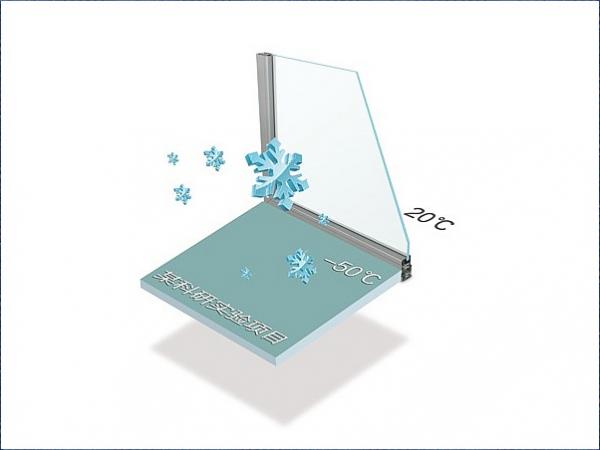

The project required a type of glass for the observation window that allow them to photo the changes in propellant morphology during mechanical testing carried out under -50℃.

They have tried various types of glass before, including triple-pane, quad-pane insulating glass and vacuum insulated glass manufactured by other companies. None of them can solve the condensation issue.

Later, the team heard about LandGlass. When they learned the performance of LandVac, they were skeptical but willing to give it a try. They ordered LandVac tempered vacuum insulated glass customized to the window size.

The first test after the installation of LandVac with almost 70℃ of temperature difference: -50℃ on one side of LandVac and 20℃ on the other side. During the test, there was no condensation in the primary visual area. The team leader felt relieved.

In the following month-long experiments, LandVac was proved to be the product that completely met the high precision optical requirements of Poisson’s ratio testing over propellant and solved the problem bothering the team for a long time. It effectively improved the team’s experimental ability and ensured the successful conclusion to the project.

Thanks to its outstanding performance, the application of LandVac in the military R&D project is a total success. As fully tempered vacuum insulated glass, LandVac adopts self-developed low temperature sealing, flexible sealing, and flat sealing technologies, demonstrating industry leading performance in thermal insulation, noise reduction, condensation resistance, safety and security, as well as superiority in product weight and thickness.

Applications of this product can be found in areas such as science research, construction, and home appliances. At present, LandVac has passed ISO9001 quality system certification, ift thermal transmittance test, sound isolation test, ATI wind resistance test, and ANSI impact resistance test. It is also the first domestic glass product that received certification approval from the Safety Glazing Certification Council (SGCC) in USA.

In the future, LandGlass will seize this opportunity and continue assisting the national military R&D projects by actively responding to the call for civil-military integration in innovation and development. In the meantime, through our innovative technologies and outstanding products, we will strive to fulfill our commitment to improve the quality of life for our users around the world.

600450

600450

Add new comment