Date: 19 October 2007

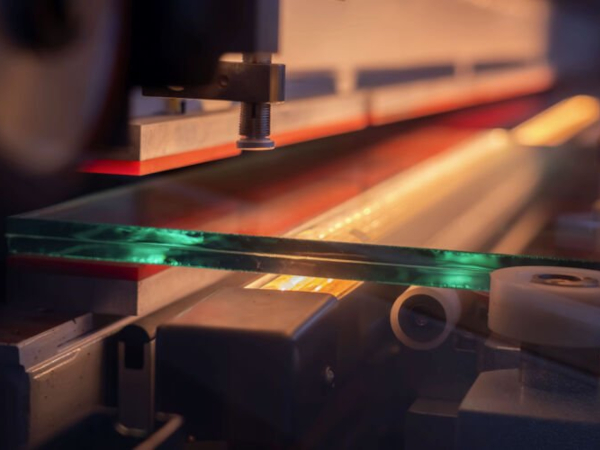

High precision edge quality is also delivered resulting in the elimination of scrap and waste.

KMT continues to pioneer the use of diamonds in the waterjet industry and these skills have been brought to bear in the design of the IDE that will define how the waterjet industry views abrasive cutting heads. For simplicity, it is designed with the fewest possible parts. The head body, orifice and mixing chamber are combined into one piece to eliminate guesswork on the wear and tear of individual parts, reduce the inventory and increase reliability. The integrated design is also a very effective and efficient way of mixing water and abrasive.

The performance of the diamond is far superior to sapphires. Longer orifice life means more uptime due to fewer orifice changes and it provides more consistent, precision cutting. Diamond orifices also improve pump performance by eliminating “orifice blowouts” which cause sharp pressure drops and pump overstroking. The venturi vacuum is very strong and consistent, eliminating problems caused by weak vacuums and leaking o-rings.

The diamond is classed at 10 on the MOHS Hardness Scale For Minerals and is virtually indestructible. The hole in the diamond is cut and shaped by an advanced process to further enhance the jet profile. It is always perfectly aligned to the centre of the focusing tube and the perfect alignment of the jet means all of the energy hits the workpiece and does not ricochet in the focusing tube. This results in a more consistent stream for a longer time, extending focusing tube life and providing a better, much more consistent cut edge to reduce scrap and eliminate waste. There is no risk of infiltration of grit during the cutting process.

The changeover from a pure water cutting head is fast and easy. Only the pure water nozzle tube has to be replaced by the IDE nozzle tube which fits into the nozzle valve. Although the IDE head is guaranteed for 500 hours, most customers can expect 1500-2000 hours.

The IDE is setting new benchmarks and industry standards in cutting head performance. As a result KMT already offers adapters so that the IDE head can be fitted to most types of waterjet systems.

Add new comment