Date: 2 October 2019

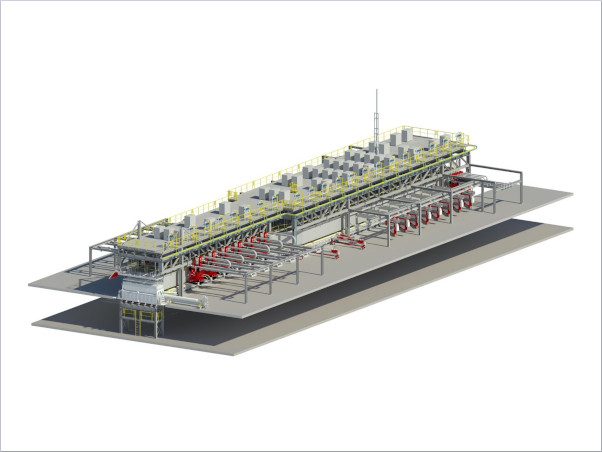

The driver and the HORN materials logistics team had to work with exceptional accuracy to load the tin bath casings onto the truck and to move them safely out of the shipping hall and the HORN factory premises.

The tin bath bottom casing is used as a support tank for the bottom refractories. It is designed to expand on heated up temperatures without flexing or distorting. When operating the hot tin bath it needs to be air-cooled continuously at the underside and at the lower side walls.

The refractory blocks are profiled to vary the tin depth. The profile design depends on the size of the bath, the products and thicknesses it is required to produce.

600450

600450

Add new comment