Date: 18 May 2017

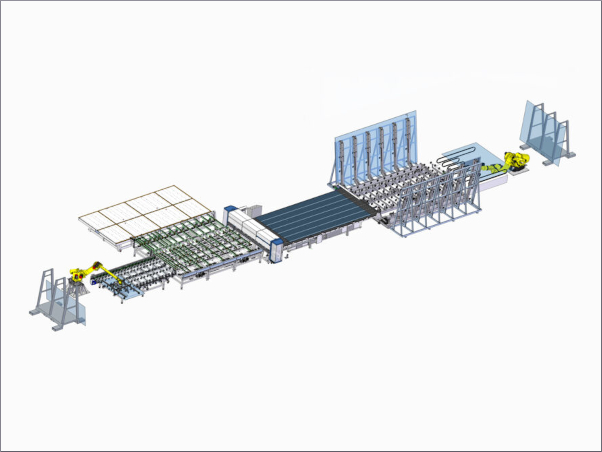

The next generation of glass production facilities in the "Cold End" achieves new efficiency levels. In the course of digitalization, self-learning systems are within striking distance.

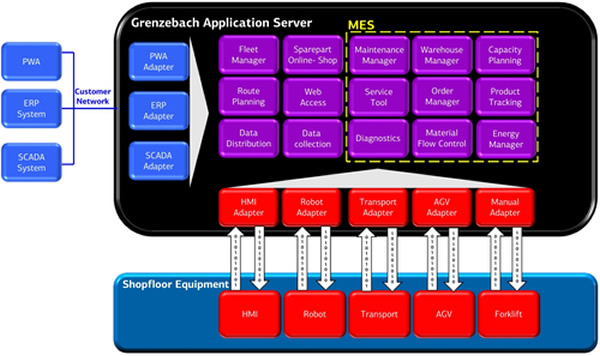

„The focus shifts from production equipment to increased efficiency of processes and monitoring of product quality“, says Christian Herfert, Director Technology & IP. The Grenzebach Application Server (GAS) is gathering all relevant data and connecting the various components as required.

In short: the GAS can be used as a highly modern, modular and centralized server for production. It integrates all equipment components and manufacturer’s devices. Thus, processes can be proactively controlled and influenced.

„Industry 4.0 has become reality in mechanical and plant engineering. With the help of the GAS, our customers can streamline tomorrow’s workflow. We also call it the Factory of the Future", says Herfert. With the use of modules, the system can be upgraded all the way to Cloud connection and refinement, for example with the Maintenance Manager.

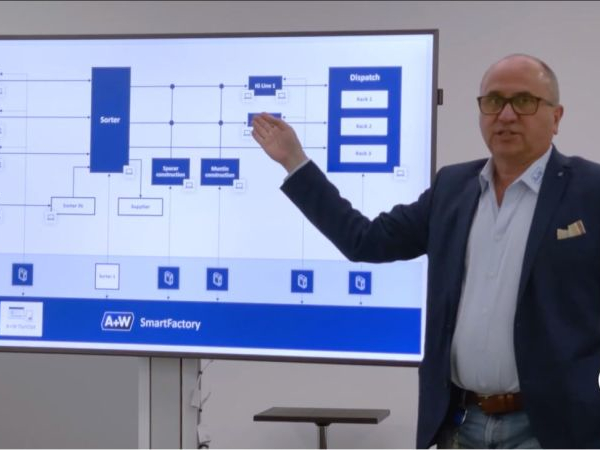

Strong, flexible and safe for personnel: Automated Guided Vehicles (AGV) are the mobile connecting links in the "Factory of the Future". The AGV fleet ensures the connection to the warehouse. The vehicles automatically transport the glass racks into the distributing stations.

Integrated laser scanners let the AGV navigate autonomously. These self-learning systems do not require any kind of modification. The transportation tasks are coordinated by the Grenzebach Fleet Manager, an application of the GAS.

Michael Haller, Industrial Security and Data Privacy, emphasizes: "In times of Industry 4.0, production routines and processes are still conducted by humans." We need a reassuring feeling regarding data protection and data privacy.

In order to protect know-how, Grenzebach focuses on transparency in data flow and business models. Industry 4.0 changes the network infrastructure and safety requirements.

In order to protect know-how, Grenzebach focuses on transparency in data flow and business models. Industry 4.0 changes the network infrastructure and safety requirements.

The currently valid security models, such as the "Guideline Industry 4.0 Security" of the VDMA (German Engineering Association), offer protection, but require further development.

Completely new tasks are being created, such as authentication, authorization or user and role management.

"Security is of great importance for all stages and for every single component of the system" says Haller.

For the "Factory of the Future", respective interfaces, various machinery and components all have to be considered and integrated into one system. Here, the Grenzebach Application Server serves as a data hub.

600450

600450

Add new comment