Date: 9 July 2020

A lead-free silver composition that can be directly applied to standard conductive coating (ITO) on glass, Conductive Silver is an integral part of a package combining black and silver inks. It provides an ideal solution for printing heating grids, bus bars, antennas, demisters, and other conductive pads and contacts.

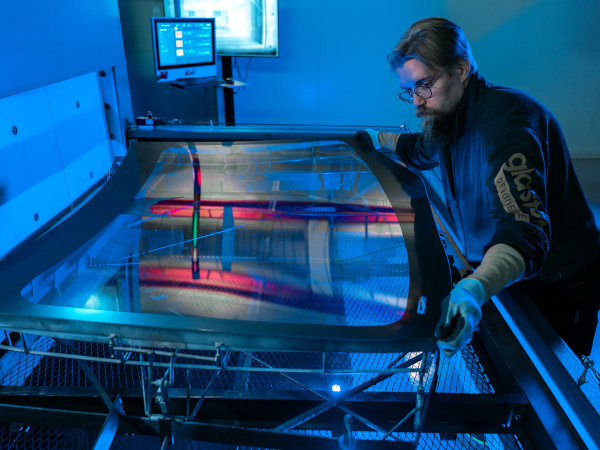

Used with Dip-Tech NEraV printers, Conductive Silver Digital Ink (CASS_0777) enables the application of high-quality conductive lines on glass with precise positioning and high speed. The printed ink layer is cured during firing, toughening, or tempering processes and provides highly conductive and tough mechanical film, enabling good soldering properties. Dip-Tech’s Conductive Silver Digital Ink’s conductivity and resistivity parameters are ideal for OEM, ARG, and specialty transportation applications.

Glass processors who have worked with Dip-Tech Conductive Silver Digital Ink say they value having a complete solution for robust and cost-effective digital printing for a wide range of automotive functions. Among other advantages, they note that using a Dip-Tech NEraV printer with Conductive Silver Digital Ink enables them to easily create the required conductivity and resistivity parameters.

Conductive Silver Digital Ink is part of Dip Tech’s automotive solution package. Comprising both machinery and a special set of inks for varied automotive applications, this comprehensive package meets the automotive industry’s most demanding standards and requirements for intensive mass production capacities.

High performance for architecture applications

Conductive Silver Digital Ink can also be used for architecture applications to create unique, high-performance elements such as electrical heated windows, glass heat radiators, alarm and security glass, anti-radiation glass, and glass illumination effects. Applied using the Dip-Tech NEraD printer, it enables glass processors to expand their offering, simplifies traditional procedures, and enables architects to work with greater creative freedom.

Used with Dip-Tech NEraV printers, Conductive Silver digital ink (CASS_0777) enables the application of high-quality conductive lines on glass with precise positioning and high speed. The printed ink layer is cured during firing, toughening, or tempering processes and provides highly conductive and tough mechanical film, enabling good soldering properties. Dip-Tech’s Conductive Silver digital ink’s conductivity and resistivity parameters are ideal for OEM, ARG, and specialty transportation applications.

Glass processors who have worked with Dip-Tech Conductive Silver ink say they value having a complete solution for robust and cost-effective digital printing for a wide range of automotive functions. Among other advantages, they note that using a Dip-Tech NEraV printer with Conductive Silver digital ink enables them to easily create the required conductivity and resistivity parameters.

Conductive Silver digital ink is part of Dip Tech’s Automotive solution package. Comprising both machinery and a special set of inks for varied automotive applications, this comprehensive package meets the automotive industry’s most demanding standards and requirements for intensive mass production capacities.

High performance for architecture applications

Conductive Silver digital ink can also be used for architecture applications to create unique, high-performance elements such as electrical heated windows, glass heat radiators, alarm, and security glass, anti-radiation glass, and glass illumination effects. Applied using the Dip-Tech NEraD printer, it enables glass processors to expand their offering, simplifies traditional procedures, and enables architects to work with greater creative freedom.

600450

600450

Add new comment