Mechanical Features: Vibration free working and movement thanks to heavy and sturdy steel construction structure, Excellent precision table surface for perfect glass cutting and high quality glass breaking, Table surface made by 22mm thick, strong MDF Long-life and smooth cushion table surface All Axis has been processed by CNC machines all at one time to catch stable structure Perfect cutting quality with Helical pinion and rack gear system, Long-life metal head cutting diamonds, Precious Cutting bridge made of Aluminium material Hydraulic tilting feature of loading table Mechanical positioning system to make glass loading and referencing Laser scanner system with electronic positioning Laser scanner system for shaped glasses Automatic safety system against cutting head falling off the glass Straight and shape glass cutting feature Low-E Edge Deletion system for straight and shape glass, Long life Metalic brush system for Low-E glass edge deletion (Patented to CMS Glass Machinery) Automatic glass cutting speed for clear and Low-E glass Hi-Tech operating head with an automatic cutting pressure, High-tech buildings with a diamond head group Automatic pressure system according to different glass thickness and shape glass, Vinyl Glass cutting feature Pneumatic breaking bars on X axis and Y axis to break the glasses easily and safely, Hydraulic System: High pressure control and safety system 2 hydraulic cylinders structure that can move very fast and secure Automatic locking system in power outage Electronic slowing and smoothly stop movement feature at the end of the deceleration Air Cushion System: Vibration and balance taken fan structure High flow rate and pressure fan structure Powerful air cushion system with blowers, Homogeneous air distribution system tray on the table surface Energy saving system thanks to the Shut-off valve system Fast positioning system with shut-off valve system that showing the effect of vacuum to the glass Optimization Software: Perfect Cut Suite with 2 keys (for office and for operator).

The software has mirroring feature for Laminated Glass Cutting.

The optimization softwares includes the following modules:

Perfect CUT Optimization Software,

Perfect CAD Drawing Software,

Perfect DXF Importing DXF files into the software library,

Perfect LABEL Label preparing and printing software,

Perfect Shape A program for parametric shape management with ready library

Perfect TV Transfers the cutting layouts to the LCD screen for easy breaking (only software)

Control System:

- Axis are controlled by servo motors to achieve the high speed

- PC based control panel with Windows operating system,

- User friendly and multi language user interface

- Data transfer to cutting section by Network cable, flash disk or any any other portable device,

- Data transfer to Automatic Profile Bending Machines,

- Remote Control System for technical assistance purposes,

- CD/DVD-ROM driver, Network Card, Wireless, 1 GB Ram, Intel Atom Processor, 300 GB Hard Disk Driver,

- 19 inch LCD wide screen,

Options:

- Electronic Safety Barrier

![]() 600450

600450

CMS Glass Machinery

2011-02-10T12:00:00

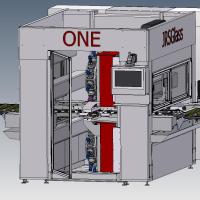

Automatic CNC Glass Cutting Table with Low-E Edge Deletion System

glassonweb.com

Add new comment