Date: 11 September 2013

Numerous tests were done using our acid-etched glass, namely our four finishes: Satinlite, Satin, Velour and Opaque.Amongst others the ASTM-501 test, which is used to measure the wear resistance, was done.Based on the results, comparing acid-etched glass and clear float glass, acid-etched glass is actually more wear resistant than float glass. The results indicate that float glass has an abrasive wear index of 183.29, whereas acid-etched glass has an abrasive wear index between 198 and 215, depending on the finish tested. The lower the number, the more susceptible to wear it is, making it less resistant.

The resistance to staining was also tested, using the ASTM-1378 test. The classification is based on how easily the stain is removed or cleaned off using different products. The higher the rating with a letter is, the better the result. All our acid-etched products were classified “A”, a rating similar to un-etched float glass.

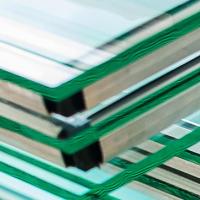

Clean-ability is affected by the pores in the glass. If we compare sandblast to acid-etching for example, we will see that the peaks and valleys are much bigger in sandblasted glass, than acid-etched glass. Even looking at different finishes of acid-etching, we can see the difference! This means the deeper the pores, the easier dirt can infiltrate, therefore making it more difficult to clean.

.jpg)

Sandblast

.jpg)

Satin

Using the MOHs test, scratch hardness was also measured. This is determined by a scale of minerals, ranked out of 1 to 10, a higher number indicating better scratch resistance. Float glass was rated a 5.5, while our acid-etched glass products rank from 5 to 7.

The final test of critical importance is the Modulus of Rupture. This test indicates that acid-etched glass is actually stronger than float glass. This is because the etching process rounds out and softens the “fractures” imbedded in the glass during the float process, making the glass able to withstand more tension, and therefore diminishing the risk of ruptures. Both etched and non etched side were tested in tension, and can endure more weight before breaking than clear float glass in tension. Please note that for this test the etched and non-etched glass came from the same float glass production batch.

Here is hoping the data from these tests provide a better understanding of the acid-etched glass properties!

Add new comment