Others also read

Unlocking energy efficiency potential: vacuum-insulated glazing for sustainable buildings - Glastory

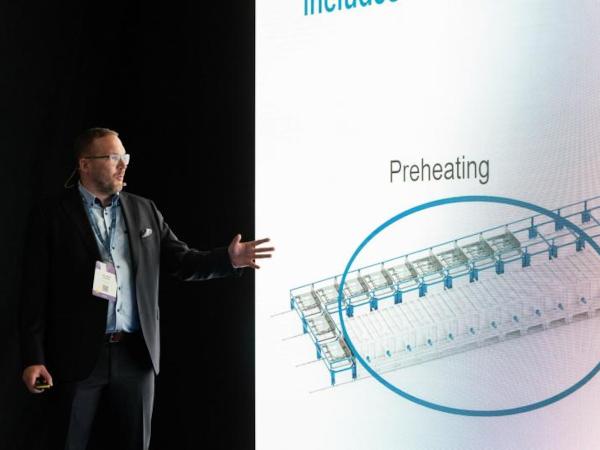

| Read more about Antti Aronen's presentation at Glass Performance Days (GPD) 2023, "An enhanced model of thermomechanical loading on a Vacuum Insulated Glazing".

| In the new Glastory post by Matthias Loppacher, we explore the evolving landscape of automotive glazing and display processing – and discuss strategies for keeping up with the changes.

| In the latest Glastory blog post, Antti Aronen introduces how the complexity of automotive windshields and sunroofs has significantly increased with evolving modern car designs.

| Christoph Timm, Principal at SOM New York, shared insights on decarbonizing the built environment and the evolving landscape of sustainable construction.

| This study provides important design guidance to the Photovoltaic (PV) solar panel development efforts using the finite element based computations of the PV module under the mechanical loadings.

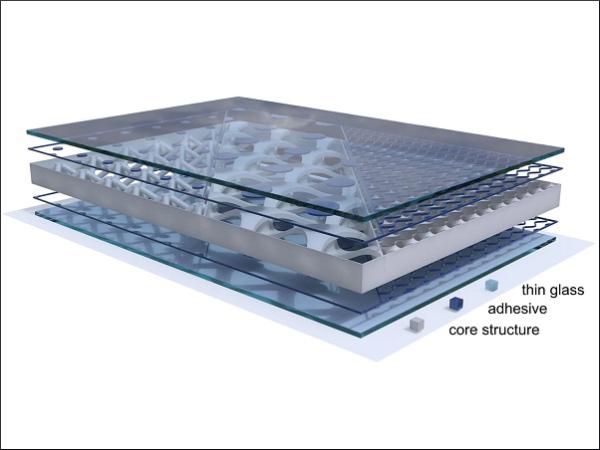

| The current paper explores how digital techniques can be used in the design and manufacturing of an innovative composite façade panel consisting of an additively manufactured polymer core and adhesively bonded thin glass outer sheets.

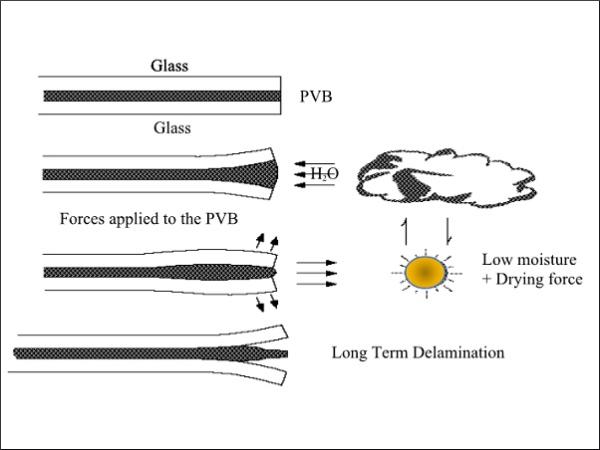

| In his blogs, Luc Moeyersons covered various subjects related to laminated glass, whether it is automotive, architectural, or photovoltaic.

| Automotive Glass Laminating Guide – Part 6

| Automotive Glass Laminating Guide – Part 5

| In the latest Glastory blog, Jukka Immonen shares some practical tips for optimizing energy consumption in automotive glass production. From preprocessing to final inspection, there is huge potential every step of the way.

| The history and benefits of laminated glass.

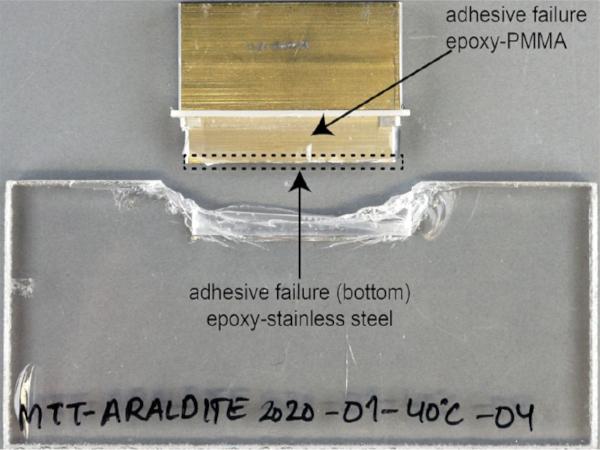

| An experimental study under tensile loading at +23, +40 and +60 °C and different glass build-ups

| In this post, we discuss what emerging designs require and how automotive glass processors can meet these requirements.

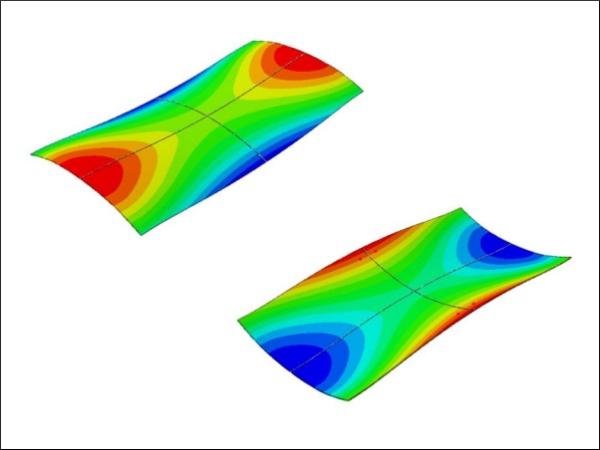

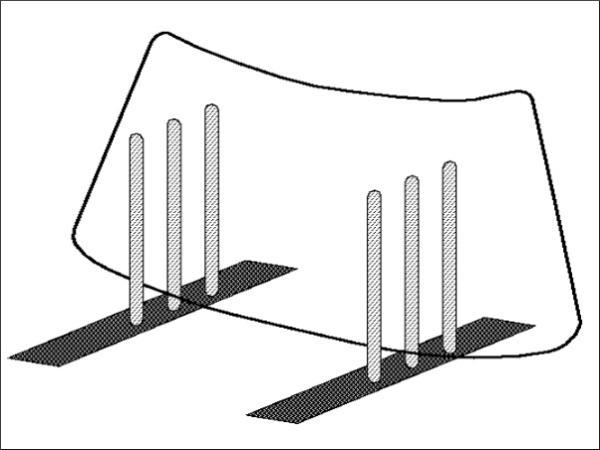

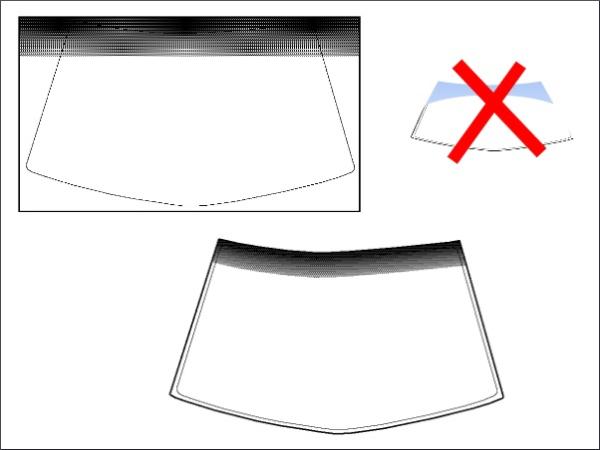

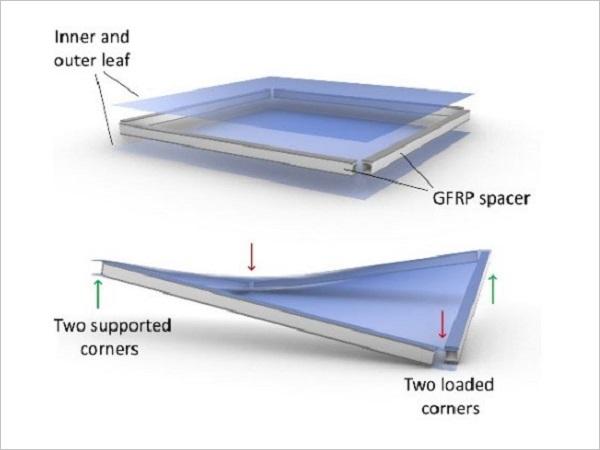

Investigations on the Cold Bending Behaviour of a Double Glazing Unit with a Rigid Edge-Spacer Frame

| In this study, the bending process of specially-fabricated double glazing units (‘panels’) is investigated with a focus on a local instability phenomenon.

| Industrial manufacture of solar building components and their integration into the building planning process

| Thin glass offers the possibility for lightweight and flexible glass façades that could change shape depending on external conditions.

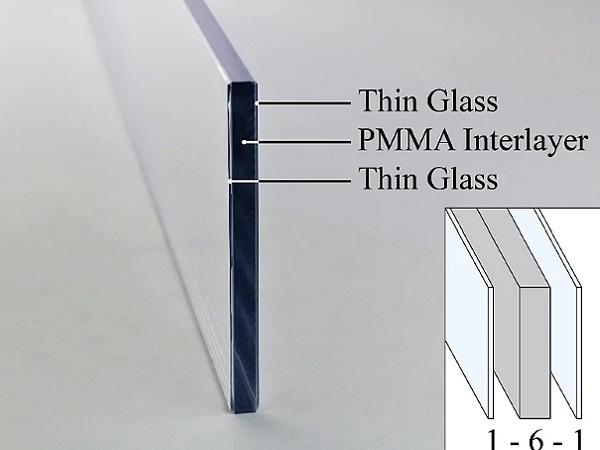

| Novel innovative glass–plastic-composite panels combining a lightweight polymer polymethylmethacrylate (PMMA) interlayer core and cover layers of thin glass are currently under development.

| The use of new generation thin, lightweight and damage-resistant glass, originally conceived for electronic displays, is moving its first steps in the built environment, in particular for adaptive and movable skins and façades.

| After seaming, grinding glass edges is another important work step in glass edge processing. The process is primarily used to remove overbreaks and underbreaks at the edges and to process the glass sheets to size.