Others also read

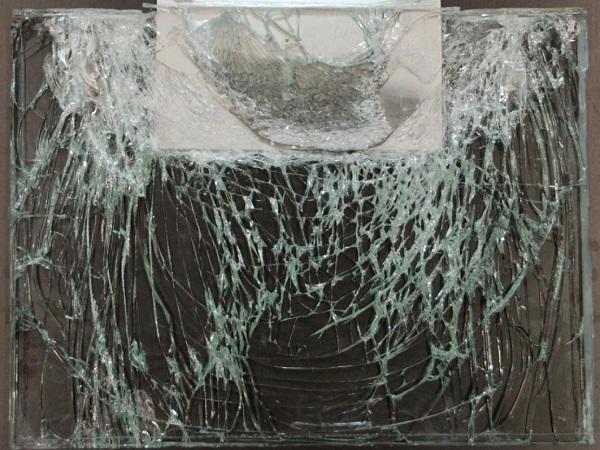

| This document provides an overview of the causes of sunburst delamination in laminated glass.

| The growing trend for transparency in contemporary architecture has fuelled the demand for load-bearing glass applications in the building industry.

| This text looks at the two systems of vertical and horizontal hot boxes, as well as the laminating cycles for PVB and EVA. It also compares the process to an autoclave PVB laminating process.

| In this text, we will discuss the advantages and disadvantages of single laminate and block autoclaving, suggested operational parameters, design of spacers, and the autoclave cycle.

| In this third episode of the #AskGlaston flat tempering series, Taneli Ylinen deals with the commonly asked question of how to handle the issues with mixed production.

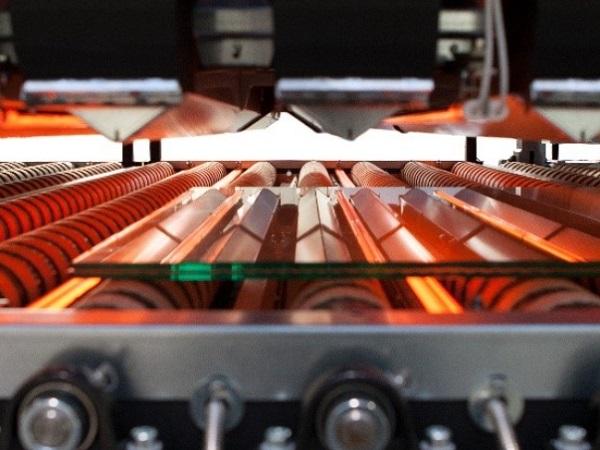

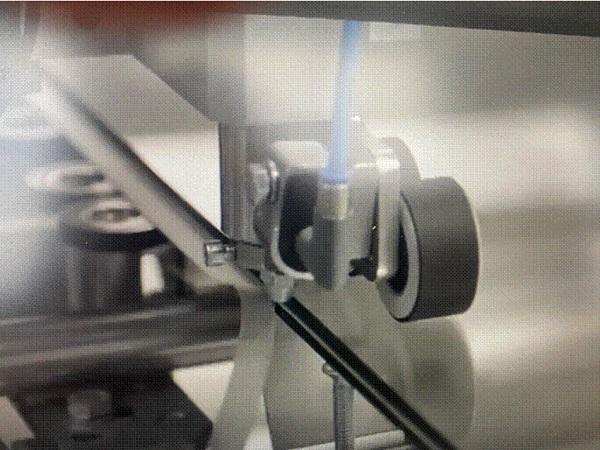

| This text takes a look at the roller process of lamination. It explores different heating concepts such as convection, long wave and short wave IR radiation, and micro-waves, as well as the importance of the correct IR radiation.

| In this post, we discuss what emerging designs require and how automotive glass processors can meet these requirements.

| This Glastory blog by Kalle Kaijanen is dealing with the processing of high-strength / structural laminates.

| Laminating glass is a process that requires precision and safety. In order to ensure that the glass is laminated safely and to a high standard, special cleanroom requirements must be met. This includes air pressure, clothing, static charges, and cleaning protocols.

| The results of the classification of hail resistance classes for different materials for greenhouse enclosures are presented in this paper.

| When we look at glass lamination, there are 3 basic systems: Nip roller system, Vacuum bag system and Autoclave free system.

| In the next session(s), Luc would like to take you through the 3 glass lamination processes in detail, going from glass and PVB requirements to design concepts.

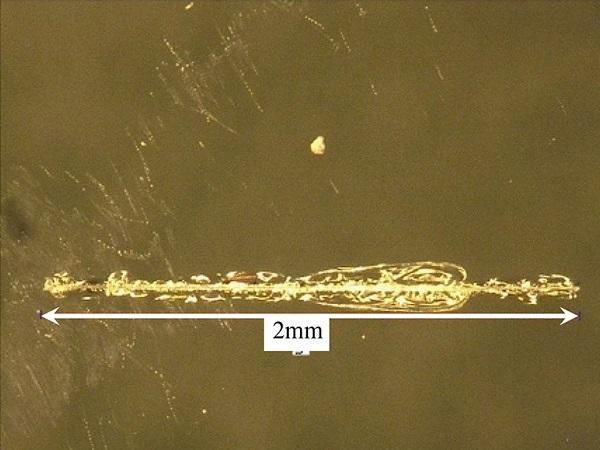

| The strength of glass plays an important role in the dimensioning of glass components in the building industry. A major factor determining float glass strength is damage such as scratches or cracks due to the brittle material behavior of glass.

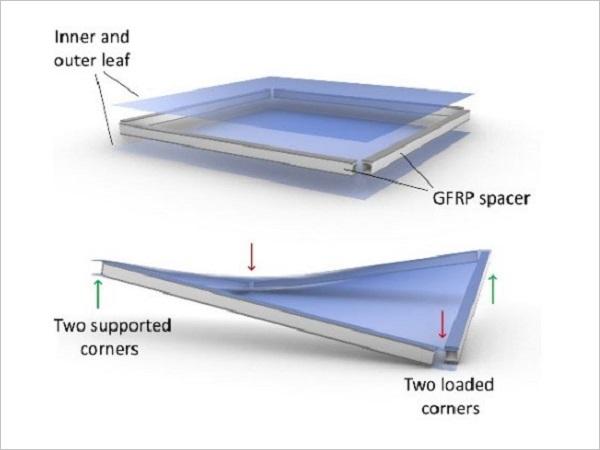

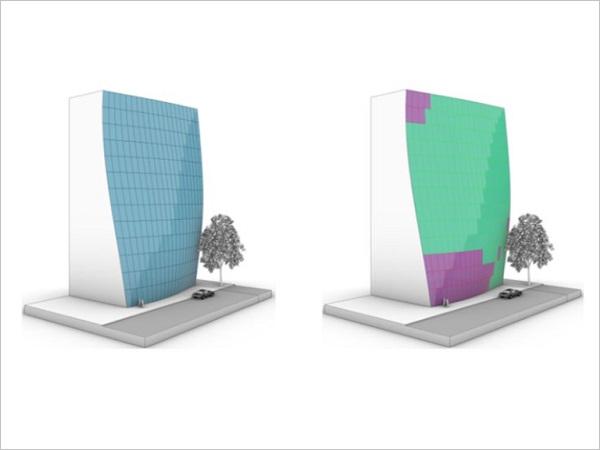

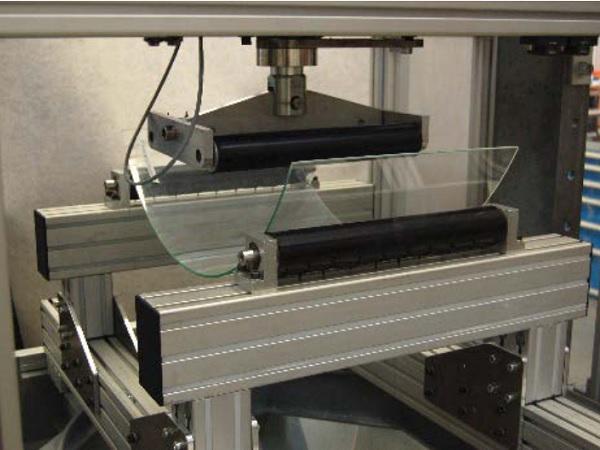

Investigations on the Cold Bending Behaviour of a Double Glazing Unit with a Rigid Edge-Spacer Frame

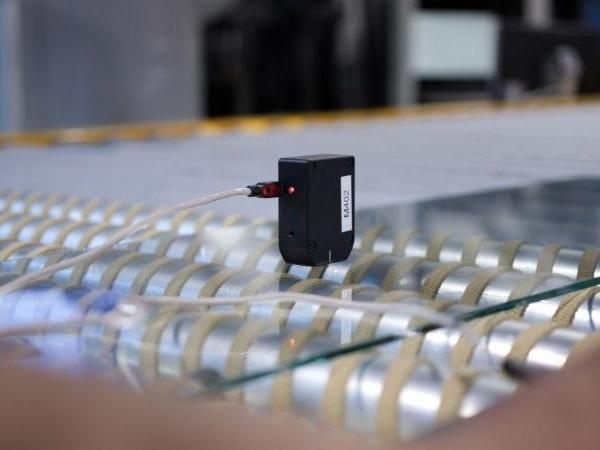

| In this study, the bending process of specially-fabricated double glazing units (‘panels’) is investigated with a focus on a local instability phenomenon.

| This paper presents work undergone for a set of four high-rise towers, featuring 11,136 unique cold-bentpanels, hundreds of which are pushed beyond 250mm.

| In this paper, we present the development of an intrinsic parameter σQM characterizing the sensitivity of a coating (or configuration) to the quench marks.

| The paper presents the results of FEM analysis as well as tests performed on double glazed units including Sikasil® IG-25 secondary sealing joints and SikaGlaze® IG-5 PIB as primary seal.

| The paper undertakes a review of basic interlayer stack data with regards to viscoelastic properties and adhesion, and the engineering hypotheses using recent preliminary fitting test results for various loading schemes.

| In the second episode of #AskGlaston Flat Tempering Series, we will talk about the new solution to estimate the stress level in glass – online.

| This first episode is devoted to the white haze phenomenon – one of the most asked about issues in the history of #AskGlaston.

| This latest Glastory blog by Miika Äppelqvist is dealing with the areas of the tempering process that can be improved to make operations more efficient.

| Industry demand for impeccable glass quality has increased notably over the last years. Customer expectations run high, forcing glass processors to strive for ever-stricter quality control and ensure minimal rejection rates for finished products.

| The most common quality issues that arise in tempered glass are roller waves, glass distortion, bad anisotropy and white haze. In this post, we want to focus on white haze and ways to control it.

| Research has shown that the general approach to determine the bending strength of thermally curved glass with the aid of the four-point bending test for flat glass according to EN 1288-3 is applicable.

| In 2015, the bold concept of a curvy tower at 252 East 57th Street, New York, was presented to an audience at the Glass Performance Days conference. At that time, building construction was just beginning, and no one was certain such a novel idea could be realized.