Article Information

- Digital Object Identifier (DOI): 10.47982/cgc.9.653

- Published by Challenging Glass, on behalf of the author(s), at Stichting OpenAccess.

- Published as part of the peer-reviewed Challenging Glass Conference Proceedings, Volume 9, June 2024, 10.47982/cgc.9

- Editors: Christian Louter, Freek Bos & Jan Belis

- This work is licensed under a Creative Commons Attribution 4.0 International ( CC BY 4.0) license.

- Copyright © 2024 with the author(s)

Authors:

- Gertjan Peters

- Erwin ten Brincke

- Josefien van der Laan Dijkhuijs

ABT Adviseurs in bouwtechniek, The Netherlands

Abstract

The adoption of glass reuse in construction faces challenges due to higher costs and more perceived risks compared to new glass. This conflicts with the goal of a circular economy. To challenge this status quo, this article explores a hypothetical scenario where glass becomes a scarce commodity. What if the float glass production process ceases to exist due to energy resource depletion, raw material scarcity, or carbon budget constraints? In such a context, glass reuse will be crucial. This article discusses the design, logistics and quality related challenges of reusing float glass, including structuralintegrity and energy performance considerations. Additionally, this article investigates the potential for glass reuse by analysing ongoing and future research, supply-demand dynamics, innovative building design, the concept of the future glass factory, and the re-evaluation and promotion of regulatory frameworks. To promote glass reuse, the article emphasizes customization over standardization. Considering the diverse dynamics of projects, from high-rise buildings to terraced houses, and varying regional construction requirements, solutions must be specific and adaptable, rather than standardized.

1.Introduction

1.1. The future scenario

Currently, the world faces the effects of ongoing climate change. To mitigate this, there is an increase in governmental regulations and other measures to reduce climate change emissions. An example is the MPG (Environmental Performance of Buildings) requirement in The Netherlands which forces engineers and architects to decrease the environmental footprint of new buildings. Additionally, natural resources are becoming increasingly scarce and their extraction has a detrimental effect on the environment as well. Sand, one of the key ingredients in the production of glass, is the second most exploited natural resource in the world (UNEP, 2022). Moreover, the current extraction rate of naturally occurring sand exceeds replenishment rates and the extraction of sand from dynamic systems has a significant impact on the environment (UNEP, 2022). In this light, it is imaginable that the current float glass process will have to change and possibly even cease to exist in the future. In this hypothetical scenario glass would become a scarce commodity that would significantly increase the value of glass. Therewith, reuse of glass would suddenly become value-enhancing rather than cost-increasing. This paper explores the questions how the increased reuse of glass will change the industryand the design of buildings. It will necessitate a different design perspective from architects and engineers as well as a substantial adjustment from the glass industry. Currently, the production of glass is based on standardization and a continuously operating float oven. In the future, however, the less predictable supply of used glass would form the basis of the production process. How would stakeholders handle this situation? And what would be the effect on the built environment? This paperexplores this intriguing future scenario.

1.2. State of the art of glass reuse

In recent years, the Netherlands has witnessed a surge in the adoption of glass reuse research. Researchers and industry stakeholders are actively engaging in exploring various aspects related to glass recycling and its sustainable applications. For example, the safety of reused glass in relation to the structural strength is researched by the TU Delft (TU Delft) and the potential for reusing glass related to the energy performance of Insulated Glass Units (IGUs) is studied by Amsterdam University of Applied Sciences. The glass industry, represented by prominent entities such as AGC and GSF, actively participates in these ongoing studies. Their involvement extends beyond mere observation, as they contribute valuable expertise and resources to advance our understanding of glass reuse.

Moreover, there are various successful applications evident in the Netherlands: GSF is producing new IGUs of 50% existing panes (e.g., in the circular renovation of 70 homes in Aalsmeer / Eigen Haard), and office windows were reused in the Natural Pavilion in Almere (see fig. 1).

2. The challenge

The challenge of this hypothetical future scenario lies both in the technical aspects of glass reuse andin matching supply with demand. How do we provide designing parties - architects and engineers - with the information they need during the design process? Furthermore, how can we guarantee the availability of suitable glass during the construction of a project? Finally, ensuring the safety of reused glass without the need for extensive destructive testing for each project emerges as a critical concern.

2.1. Supply and demand

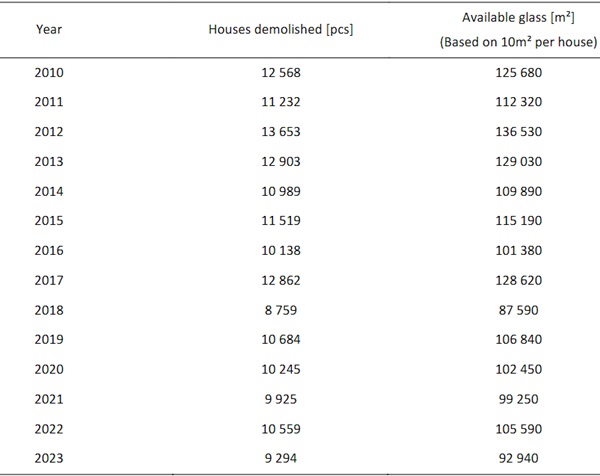

Drawing upon available data, it is possible to derive estimations regarding the quantity of glass that will become accessible for reuse. According to statistics from the Dutch government (Statline, n.d.)approximately 155,000 houses were demolished between 2010 and 2023, averaging 11,000 houses per year. Given an assumption of 10 m² of insulated glass per house during demolition, it can be inferred that approximately 110,000 m² of insulated glass could have been recovered from these buildings (as indicated in Table 1). It is reasonable to hypothesize that in the foreseeable future, equivalent quantities of glass will be available for the purpose of reuse. This corresponds to estimated annual CO2 savings of 4,400,000 kg (NMD database, n.d.).

Table 1: Estimation of the amount of used glass potentially available per year based on data on demolished houses per year (Statline, n.d.)

Alternatively, estimates on the future availability of used glass can be made using five key indicators.

- Warranty period: 10 years

- Decline in energy performance: 15 years (Amsterdam University of Applied Sciences, 2024)

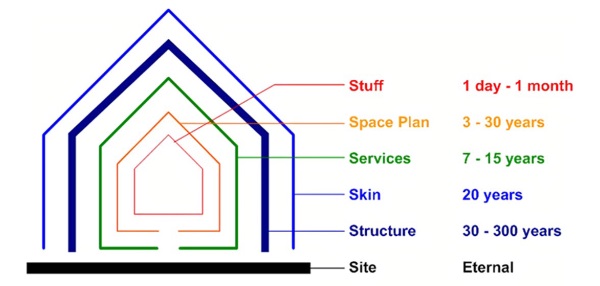

- S-layers model by Brand: 20 years (Brand, 1994)

- Technical lifespan of glass in façades: 30 years (SBR, 2012)

- Technical design lifespan of float glass: 50 years (NEN 2608:2014)

The S-layers (shearing layers) concept was initially mentioned by Frank Duffy, and later further developed by Steward Brand in his book “How Buildings Learn: What Happens After They're Built"(Brand, 1994). The idea of this concept is that different processes within a building operate on different timescales. For example, the “structure” layer of a building has a lifespan of thirty to three hundredyears whereas the “space plan” layer has a lifespan of just three to thirty years. To accommodate these different timescales, slower layers should not obstruct (the replacement of) faster layers. Otherwise,there is a risk that the whole building is retired early. Within this framework, glass in the façade is classified as a “skin” layer, a category alleged to have a lifespan of 20 years (Brand, 1994).

Based on the indicators above, it is reasonable to assume that insulated glass in most buildings will be replaced between 15 and 25 years. Applying this information to data on the construction dates of buildings can predict more specifically when and how much glass will be available in the future.

In the future, making predictions of the quantity and quality of available glass will be easier and more accurate by implementing artificial intelligence. For example, by collecting knowledge over the coming years on the structural strength of existing glass and the possibilities for enhancing its energy performance and linking this to building stock data (including construction year, location, dimensions, orientation, and environmental factors), we can develop a model that allows quick and reliable predictions of the quantity and quality of available glass in a given period.

2.2. Design for reuse

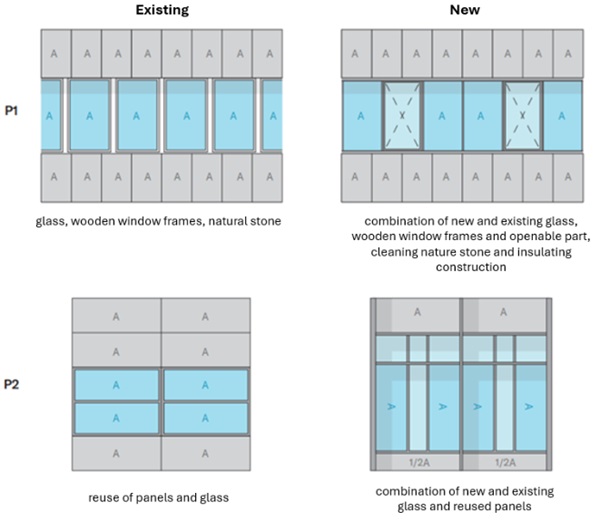

If we can predict the supply of reusable glass, we can use this information for design purposes. The reuse of glass will require additional creativity from architects to create contemporary architecture with existing materials and design new façades with predetermined dimensions. It also demands ingenuity from engineers to ensure a safe façade using materials whose strength has decreased over time (TU Delft n.d.) and is further compromised by damage and contamination. Another challenge is to restore the desired energy properties in new insulated glass units (IGUs). Currently, we observe that the reuse of glazing is gradually taking off. The renovation of the Palace of Justice in The Hague is an example of what such a design process can look like (Nudus, n.d.). Here we are designing with existing glass from the same building which results in an entirely new façade appearance (see fig. 3). We observe that currently, the reuse of glass is primarily being explored in the renovation of utility buildings. However, glass reuse also presents significant opportunities for residential construction. The dimensions in serial housing construction are often modular, making them highly interchangeable and particularly suitable for applying used glass.

2.3. Development of technology

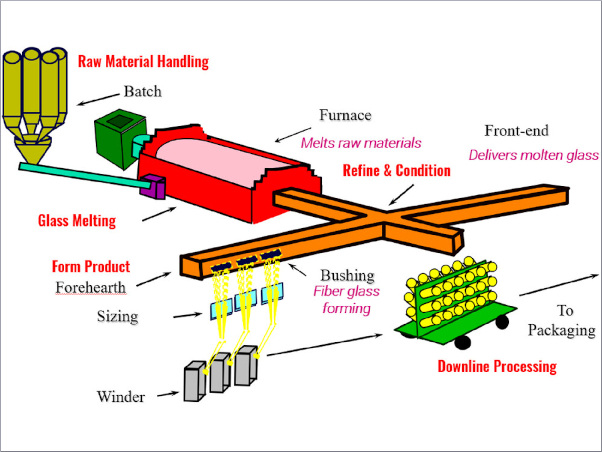

Producing new IGUs with reused glass requires a new production process. This begins with the dismantling of existing glass, a task that must be executed with care to prevent damage and maintain quality. Subsequently, the glazing needs to be separated, cleaned, and scanned for damages and impurities. Glass which meets quality standards can then be directly incorporated into new IGUs. For glass with minor structural damages, repair methodologies will need to be developed. Similar methodologies are already used in the automotive industry (e.g., HPX4® / Carglass), but alternative technologies are conceivable. Moreover, technology for the reuse of coatings need to be developed. Initially, this pertains to low-e coatings, followed by solar control coatings. A significant portion of the current glass stock in buildings consists of coated glass. For this to be reused in new IGUs, further research is required (oxidation processes, scanning techniques, repair methods, warranties).Concerning safety glass, PVB interlayers and other types of interlayers must be detachable and reusable. This also necessitates extensive research, drawing upon expertise from across the glass market. The glass factory of the future (see fig. 4) will need to be highly flexible regarding supply and demand. Additionally, new scanning and repair techniques will be introduced. Ideally, all processes are to be performed at a single location and to minimize transportation, the locations of new glass factories must be strategically determined.

3. Conclusion and next steps

To stimulate the reuse of glass, various measures and initiatives are necessary:

- Understanding the future availability and quality of reusable glass is necessary for architects and engineers to design effectively with used glass. An AI model that integrates supply and demand data with technical quality information can facilitate the incorporation of reused glass into design projects.

- It is essential that the industry is motivated to reuse glass as part of the circular economy. This requires a shift in the mindset and market strategy of companies, offering business opportunities for glass manufacturers shifting from global to local.

- Investing in research and the development of new technologies and methods for glass reuse can improve the efficiency and effectiveness of the process, making it more attractive for companies to reuse glass. By combining these measures, we can promote glass reuse and contribute to a more sustainable and circular construction sector.

- Government regulations can play a significant role in encouraging glass reuse. For instance, tightening the Environmental Performance of Buildings (MPG) standards and establishing legal requirements for CO2 budgets per project can positively impact glass reuse. An alternative could be the implementation of a CO2 tax, though this might not be preferable due to its potential impact on project feasibility. However, the process of changing legislation requires considerable time, a luxury we cannot afford given the climate challenges we are facing.

Acknowledgements

The authors would like to thank TU Delft and the Amsterdam University of Applied Sciences for allowing ABT to contribute to research projects related to glass reuse. Additionally, ABT wishes to thank AGC for their practical support with project-related inquiries. We hope that linking these studies to current and future projects will accelerate the reuse of glass.

References

Amsterdam University of Applied Sciences: https://www.hva.nl/kc-techniek/gedeelde-content/projecten/circular-transition/elke-ruit-een-tweede-leven-hergebruikt-isolatieglas.html (n.d.) Accessed 30 May 2024

Brand, S.: How Buildings Learn: What Happens After They're Built. (1994)

Carglass: https://www.carglass.nl/resource-center/krachtige-ruitreparaties-met-hpx4r (n.d.) Accessed 30 May 2024

GSF: https://gsfglasgroep.nl/circulair-bouwen-is -de-toekomst/ (n.d.) Accessed 30 May 2024

Nationale Milieudatabase: https://milieudatabase.nl/nl/viewer/ (n.d.). Accessed 30 May 2024

NEN 2608:2014 Vlakglas voor gebouwen. (1 October 2014)

Nudus: Preliminary Design – Renovation Palace of Justice The Hague. https://nudus.eu/project/paleis-van-justitie (n.d.) Accessed 30 May 2024

The Natural Pavilion: https://www.thenaturalpavilion.eu/materialisatie/ (n.d.) Accessed 30 May 2024

Sofokleous, I.: Methodology for the prediction of the strength of naturally aged glass based on surface flaw characterization https://repository.tudelft.nl/islandora/object/uuid%3Ab6ad7619-da9c-448c-aaf4-10cd065bbe14 (n.d.) Accessed 30 May 2024

SBR: Levensduur van bouwproducten, methode voor referentiewaarden. (2011)

StatLine: Voorraad woningen; standen en mutaties vanaf 1921. https://www.cbs.nl/nl-nl/cijfers/detail/82235 NED (n.d.). Accessed 30 May 2024

Stuurstraat, N.: Strength of naturally aged glass units determined by experimental testing: Glass Reuse. https://repository.tudelft.nl/islandora/object/uuid%3A1f5681dc-785e-4f1f-b047-499c83ddc46d (n.d.) Accessed 30 May 2024

UNEP: Sand and Sustainability: 10 strategic recommendations to avert a crisis. (2022)